Method for preparing aln green ceramic sheet for multilayer wiring substrate by tape casting method and prepared aln green ceramic sheet

A multi -layer wiring substrate and flowing technology, which is applied in the field of Aln raw porcelain and its current preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

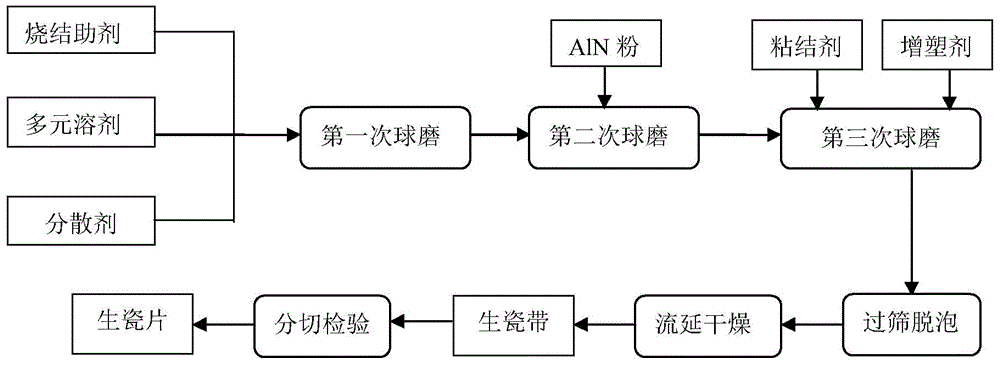

Method used

Image

Examples

Embodiment 1

[0042] Cast 0.100mm thick green ceramic sheet

[0043] The average particle size of AlN powder is 1.2μm, the specific surface area (BET) is 3.4㎡ / g, the oxygen content is less than 0.9% (weight percent), Y 2 o 3 , CaO powder particle size are in the range of 0.8 ~ 3.0μm.

[0044] In this example, the ingredients are prepared according to the following proportions:

[0045] AlN powder weight percentage is 47%

[0046] The weight percentage of sintering aid is 2.5%

[0047] The weight percentage of dispersant is 0.95%

[0048] Binder weight percentage is 8.5%

[0049] Multicomponent solvent weight percentage is 37.3%

[0050] Plasticizer percentage is 3.75%

[0051] 1) Prepare a 3.5kg batch for casting. Weigh the dispersant, sintering aid and multi-component solvent according to the above ratio. The solvents are mixed and poured into a ball mill jar, and then the sintering aid and the dispersant are respectively added to the multi-component solvent and stirred. Carry ou...

Embodiment 2

[0066] Cast 0.168mm thick green ceramic sheet

[0067] The average particle size of AlN powder is 1.2μm, the specific surface area (BET) is 3.4㎡ / g, the oxygen content is less than 0.9% (weight percent), Y 2 o 3 , CaO powder particle size are in the range of 0.8 ~ 3.0μm.

[0068] In this example, the ingredients are prepared according to the following proportions:

[0069] AlN powder weight percentage is 47%

[0070] The weight percentage of sintering aid is 2.5%

[0071] The weight percentage of dispersant is 0.95%

[0072] Binder weight percentage is 8.5%

[0073] Multicomponent solvent weight percentage is 37.3%

[0074] Plasticizer percentage is 3.75%

[0075] 1) Prepare a 3.5kg batch for casting. Weigh the dispersant, sintering aid and multi-component solvent according to the above ratio. Mix the solvents and pour them into the ball mill tank, then add the sintering aid and dispersant to the multi-component solvent and stir, and then perform the first ball mill af...

Embodiment 3

[0089] Cast 0.270mm thick green ceramic sheet

[0090] The average particle size of AlN powder is 1.2μm, the specific surface area (BET) is 3.4㎡ / g, the oxygen content is less than 0.9% (weight percent), Y 2 o 3 , CaO powder particle size are in the range of 0.8 ~ 3.0μm.

[0091] In this example, the ingredients are prepared according to the following proportions:

[0092] AlN powder weight percentage is 48.3%

[0093] The weight percentage of sintering aid is 2.58%

[0094] The percentage of dispersant is 0.97%

[0095] Binder percentage is 5.8%

[0096] Multicomponent solvent weight percentage is 38.4%

[0097] Plasticizer percentage is 3.95%

[0098] 1) Prepare a 7kg batch for casting. Weigh the dispersant, sintering aid and multi-component solvent according to the above ratio. The solvents are mixed and poured into a ball mill jar, and then the sintering aid and the dispersant are respectively added to the multi-component solvent and stirred. Carry out ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com