Additive manufacturing device and method

A technology of additive manufacturing and fixing seat, applied in the field of additive manufacturing, can solve the problems of poor structure and mechanical properties of workpieces, and achieve the effect of simple and convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

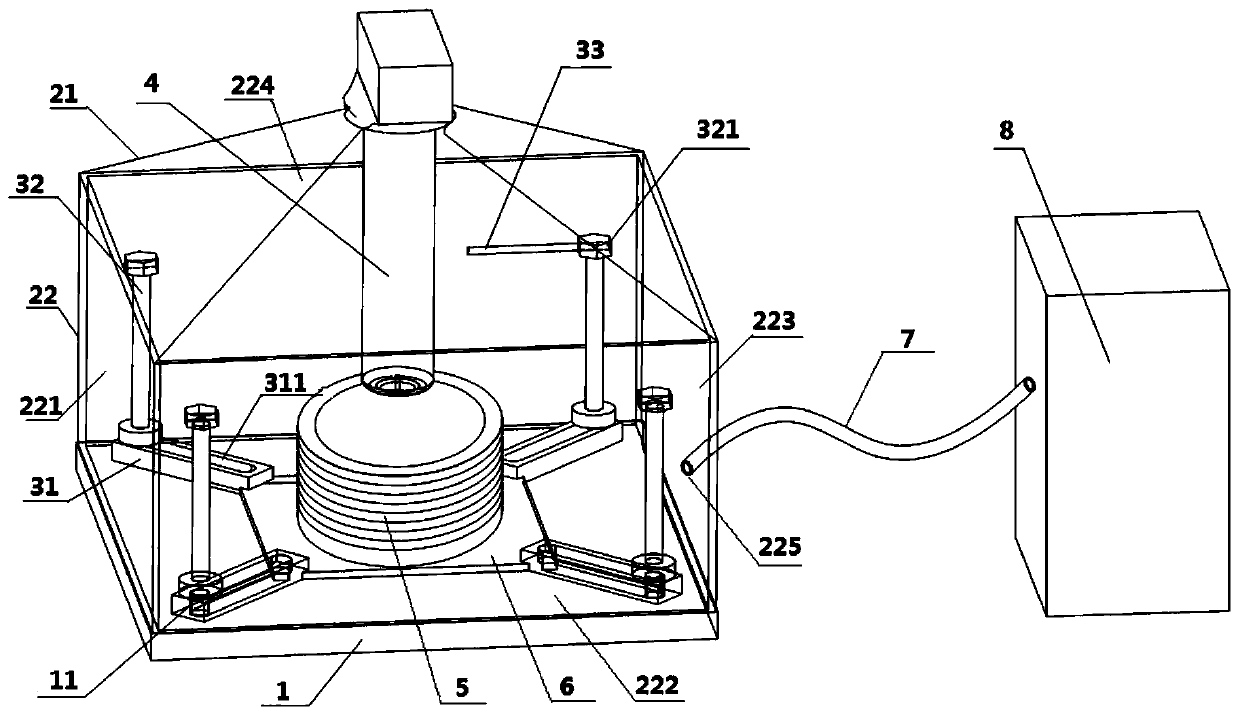

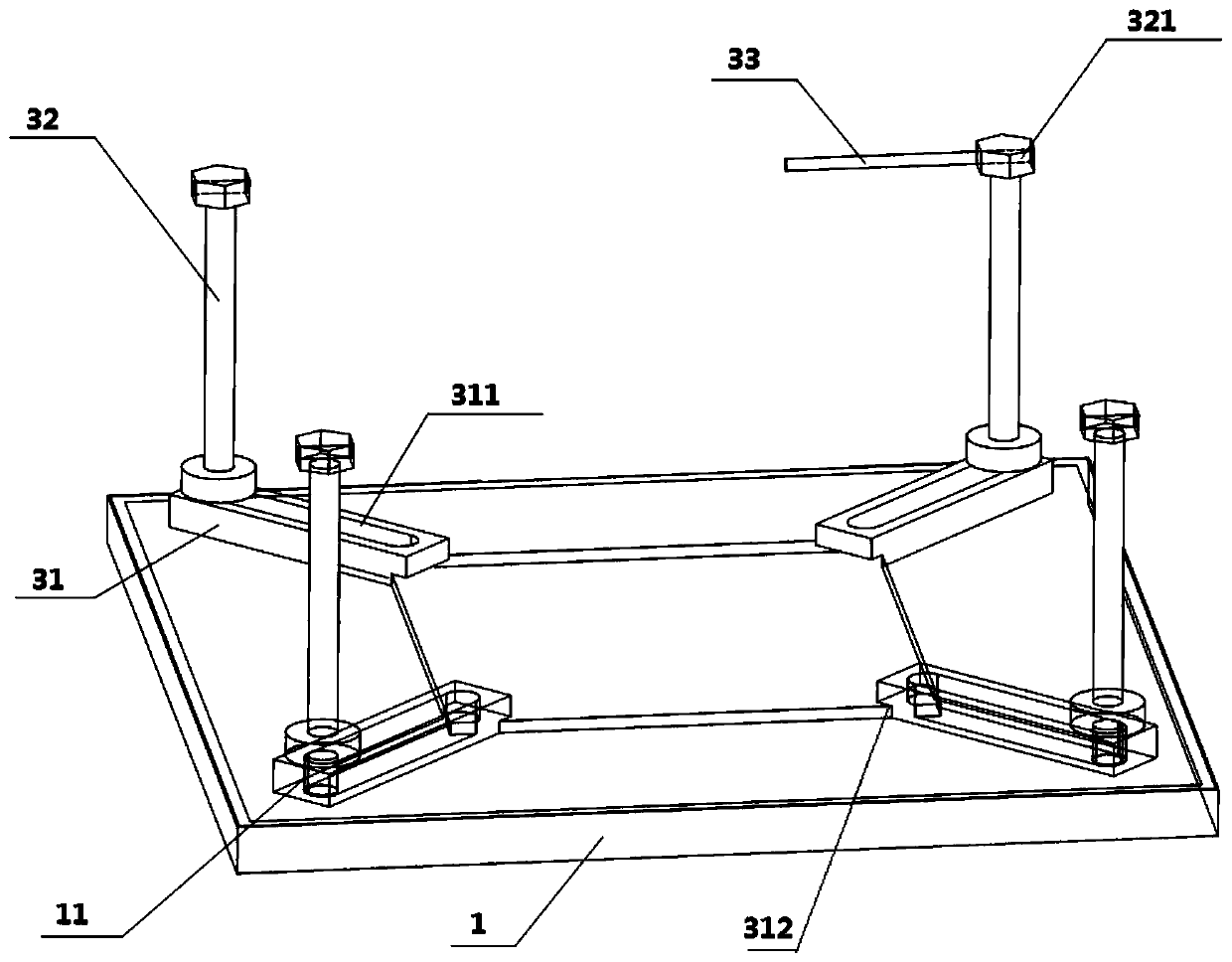

[0103] Please also refer to figure 1 and figure 2 , the present embodiment provides an additive manufacturing device, which includes a protective cabin and a metal fixing seat 1 . The protective cabin includes a connecting portion 21 and a transparent protective cover 22. One end of the connecting portion 21 is used to connect with the mechanical arm holding the welding torch 4, and the other end is connected with the transparent protective cover 22; The seat 1 is connected, and a manufacturing space for additive manufacturing is formed between the transparent protective cover 22, the connecting portion 21 and the fixed seat 1, and the transparent protective cover 22 is provided with an air hole 225 communicating with the manufacturing space for introducing protective gas. The shielding gas is input into the manufacturing space through the hose 7 communicating with the shielding gas supply device 8 and the manufacturing space.

[0104] Wherein, the connection part 21 is a f...

Embodiment 2

[0108] This embodiment provides an additive manufacturing method, using the additive manufacturing device provided in Embodiment 1 to perform additive manufacturing on the substrate 6 according to the following steps:

[0109] A. Install the substrate 6 on the fixing seat 1 and fix it by clamping parts. Wherein, the fixed seat 1 is placed on the turntable of the positioner.

[0110] B. Put the protective cabin on the fixed seat 1 to cover the base plate 6 . Adjust the mechanical arm so that the moving range of the welding torch 4 is within the range of the protective cabin.

[0111] C. Determine the starting position of the welding torch 4 (that is, the arc starting point), and write the additive manufacturing program.

[0112] D. The flexible connection part 21 is connected and fixed to the mechanical arm, and an appropriate gap is left during the connection process to facilitate the discharge of harmful gases.

[0113] E. Connect the other end of the hose 7 filled with ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transverse strength | aaaaa | aaaaa |

| Longitudinal strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com