Water-based double-component epoxy self-leveling floor paint and preparation method thereof

A water-based two-component, epoxy technology, used in epoxy resin coatings, coatings, polyamide coatings, etc., can solve problems such as volatilization of organic solvents, and achieve the effect of eliminating air bubbles, good fullness, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

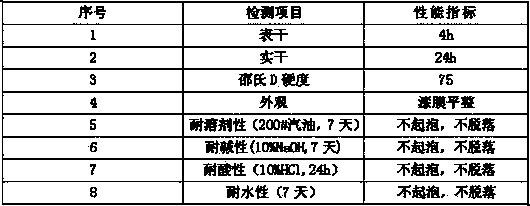

Image

Examples

Embodiment 1

[0031] Embodiment 1--making 1100 kilograms of water-based two-component epoxy self-leveling floor paint:

[0032] Raw materials used:

[0033] Component A, modified self-emulsifying water-soluble polyamide resin 100 kg, polycarboxylate sodium salt 8 kg, polyether modified siloxane 5 kg, titanium dioxide 60 kg, precipitated barium sulfate 150 kg, quartz powder 250 kg kg, 300 kg of quartz sand, 5 kg of alkali thickening rheology additive, and 122 kg of water;

[0034] Component B, national standard E51 epoxy resin 85 kg, glycidyl ether 15 kg.

[0035] The production steps are as follows:

[0036] A component

[0037] A, first inject 100 kilograms of modified self-emulsifying water-soluble polyamide resins and 122 kilograms of water into the reactor;

[0038] B. Start the mixer and add 8 kilograms of polycarboxylate sodium salt and 5 kilograms of polyether-modified siloxane into the reaction kettle successively at a stirring speed of 400-600 rpm, and stir for more than 10 min...

Embodiment 2

[0046] Embodiment 2--making 1100 kilograms of water-based two-component epoxy self-leveling floor paint

[0047] The raw materials used are:

[0048] Component A, modified self-emulsifying water-soluble polyamide resin 150 kg, polycarboxylate sodium salt 5 kg, polyether modified siloxane 2 kg, titanium dioxide 40 kg, precipitated barium sulfate 100 kg, quartz powder 300 kg Kilogram, 350 kilograms of quartz sand, 3 kilograms of alkali thickening rheology additive, 50 kilograms of water;

[0049] Component B, national standard E51 epoxy resin 90 kg, glycidyl ether 10 kg;

[0050] The production steps are as follows:

[0051] A component

[0052] A, first inject 150 kilograms of modified self-emulsifying water-soluble polyamide resins and 50 kilograms of water into the reactor;

[0053] B. Start the mixer and add 5 kilograms of polycarboxylate sodium salt and 2 kilograms of polyether modified siloxane to the reaction kettle successively at a stirring speed of 400-600 rpm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com