Biomass particle fuel machine with vertical conical roller and conical die

A biomass particle and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of heat and wear of components, power consumption, large torque, etc., to reduce the starting overload part, reduce the processing difficulty, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

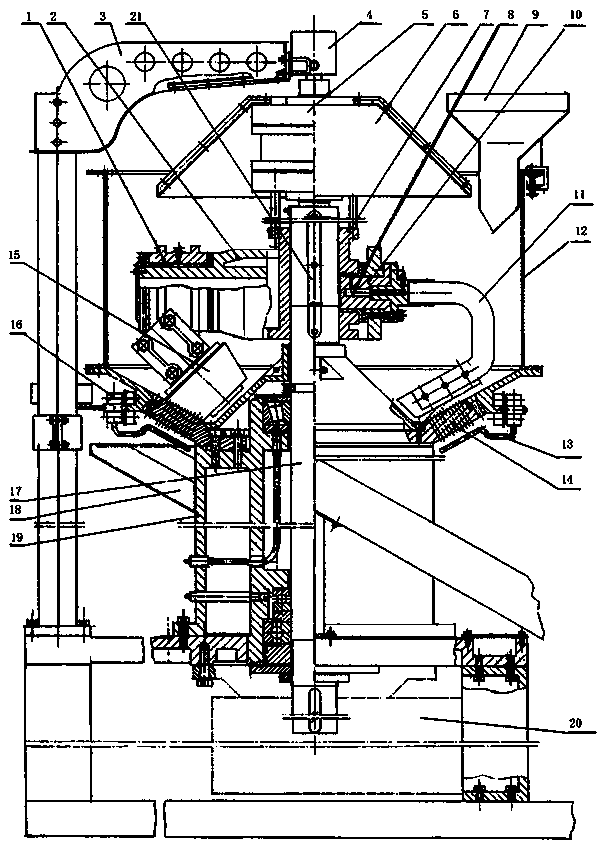

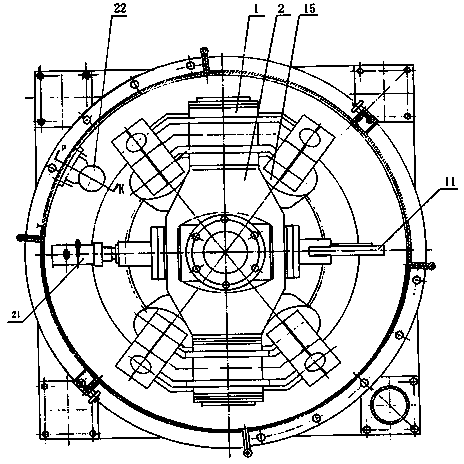

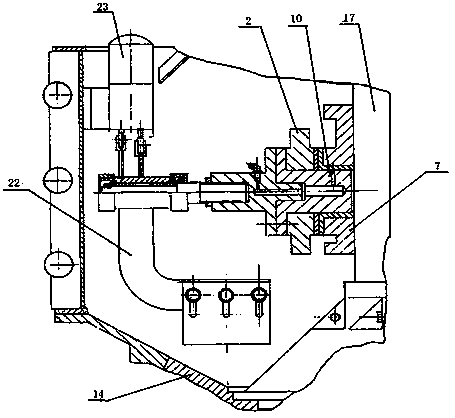

[0025] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

[0026] The invention includes a cross arm 1, a swing shaft 2, an oil guide cylinder stopper bracket 3, an oil guide cylinder 4, an oil cylinder 5, a cone cover 6, a pressure sleeve 7, a pressure short shaft 8, a feeding hopper 9, a pressure short shaft 10, and a material spreader Laying swing scraper 11, silo 12, feeder 13, conical ring die 14, pressure roller 15, feeder roller 16, main shaft 17, discharge chute 18, frame 19, motor reducer 20, flat Key 21, Swing scraper 22, Material quantity control switch 23, Swing arm 24, Roller 25, Gear iron tappet 26, Connecting rod 27, Stop iron 28, Travel switch 29, Tappet 30, Pressure roller sleeve 31, Bearing cover 32. Pressure roller shaft 33, seal ring 34, seal ring 35, screw plug 36, bearing 37, oil cup 38, oil guide cylinder 39, oil guide rod 40, oil inlet and outlet 41, oil outlet 42, ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com