Immobilized algal toxin degrading enzyme as well as preparation method and application thereof

A technology for degrading enzymes and fossils of algae toxins, applied to chemical instruments and methods, fixed on or in inorganic carriers, water pollutants, etc., can solve the problems of less reuse times, low enzyme stability, and difficult control of the reaction process, etc. problems, to achieve the effect of increasing the number of reuse, high degradation rate, and strict control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing an immobilized algae toxin-degrading enzyme, wherein the method comprises the following steps:

[0022] (1) In the presence of the first solvent, the graphene oxide is activated and separated from solid and liquid with a carboxyl activator to obtain activated graphene oxide;

[0023] (2) In the presence of the second solvent, the activated graphene oxide obtained in step (1) is contacted with the functionalized iron ferric oxide nanoparticles and separated into solid and liquid to obtain a solid phase carrier;

[0024] (3) loading algae toxin-degrading enzymes on the solid phase carrier,

[0025] Wherein, the functionalized iron ferric oxide nanoparticles are amino functionalized iron ferric oxide nanoparticles, carboxyl functionalized iron ferric oxide nanoparticles, azido functionalized iron ferric oxide nanoparticles and sulfhydryl One or more of the functionalized iron ferric oxide nanoparticles; the weight ratio of the...

preparation example 1

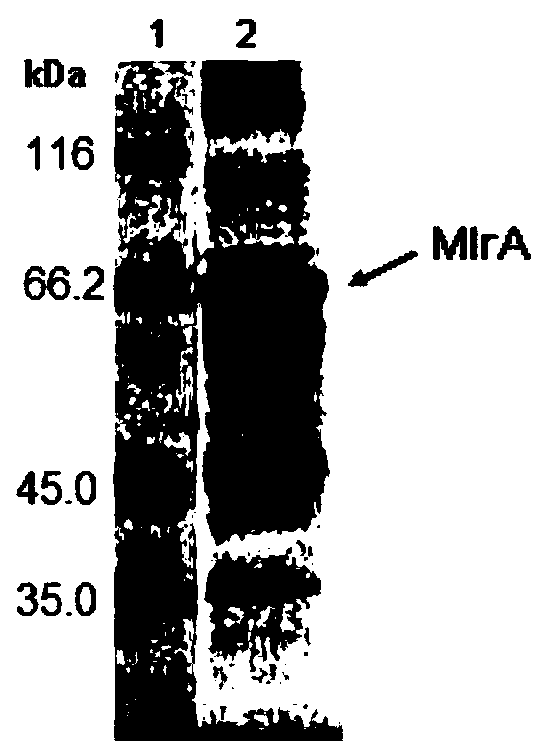

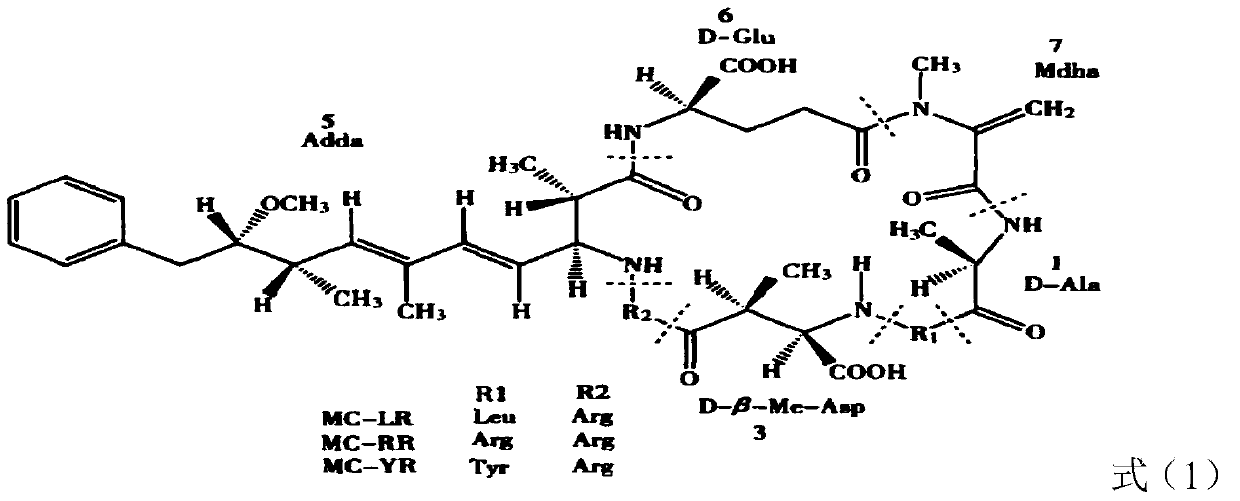

[0071] This preparation example is used to illustrate the preparation method of algae toxin degrading enzyme.

[0072] The MlrA coding sequence (Accession Number: AF411068) was constructed on the prokaryotic expression vector pMAL-C2X (inserted between the BamHI and HindIII restriction sites) to obtain the expression vector pMAL-C2X-MlrA expressing MlrA. For the specific construction method, see Molecular Cloning Experimental Guide, Third Edition (J. Sambrook et al., Science Press, 2002) Chapters 1 and 15.

[0073] Take the prepared competent DH5α out of the refrigerator and freeze-thaw on ice, add 10 μL of the ligation product (expression vector pMAL-C2X-MlrA), reset the EP tube in ice for 30 minutes, and then put it in a 42°C Place in a water bath for 90 seconds, then put it in ice and let it stand for 5 minutes. Add 600 μL of LB medium to each tube, incubate in a shaker at 37°C and 180 rpm for 70 min; then centrifuge at 4000 rpm, take 600 μL of supernatant, mix the precipi...

Embodiment 1

[0079] This example is used to illustrate the immobilized algal toxin degrading enzyme and its preparation method of the present invention.

[0080] 2 mg GO (5 μm, purchased from Nanjing Xianfeng Nano Material Technology Co., Ltd., XF002) was added to 2 ml of water, and ultrasonically dispersed at 100 W and 25 ° C for 3 h to obtain a GO solution. 20 mg of EDC (purchased from Shanghai Covalent Chemical Technology Co., Ltd.) and 10 mg of NHS (purchased from Wuhan Chucheng Zhengmao Technology Engineering Co., Ltd.) were dissolved in 1 mL of MES (pH=5.2) and added to the above GO solution , contacted at 30° C. for 30 min, then separated the solid from the liquid, and washed the obtained solid phase with PBS (pH=7) for 3 times. Disperse the washed solid phase with 2mL of PBS (pH=7.4), add 0.4mg of amino-functionalized iron ferric oxide nanoparticles (100nm, purchased from Tianjin Beisile Chromatography Technology Development Center, trademark 3611), at 25 It was contacted at ℃ for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com