Biomedical TiNbSn-HA composite material with low elastic modulus and preparation method of biomedical TiNbSn-HA composite material

A low elastic modulus, biomedical technology, applied in the field of composite materials and their preparation, can solve problems such as implant shedding, elastic modulus mismatch, stress shielding, etc., and achieve low elastic modulus, excellent compressive strength and compression. Effects of elastic modulus, good biocompatibility and bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: A low elastic modulus biomedical TiNbSn-HA composite material described in this embodiment, a low elastic modulus biomedical TiNbSn-HA composite material consists of 34.0% to 37.0% by weight of Nb, 2.0%-5.0% of Sn, 5%-20.0% of HA and the balance of Ti are prepared.

[0016] The beneficial effects of this embodiment are: the low elastic modulus titanium alloy / HA composite material of this embodiment is a TiNbSn-HA composite material, and the composite material belongs to the composite material with β-type titanium alloy as the matrix. The low elastic modulus biomedical TiNbSn-HA composite material of this embodiment has a compressive strength of 830MPa to 880MPa and an elastic modulus of 20Gpa to 30Gpa, exhibiting excellent compressive strength and compressive elastic modulus, which are comparable to the elastic modulus of natural human bones. Therefore, the TiNbSn-HA composite material prepared in this embodiment not only has a lower elastic modulus but al...

specific Embodiment approach 2

[0018] Specific embodiment 2: The preparation method of a low elastic modulus biomedical TiNbSn-HA composite material described in this embodiment is specifically carried out according to the following steps:

[0019] 1. Weighing: 34.0% to 37.0% by weight of Nb, 2.0% to 5.0% of Sn, 5.0% to 20.0% of HA and the balance as Ti, weigh Nb powder, Sn powder and nano HA powder respectively and Ti powder as raw materials;

[0020] 2. Preparation of mixed powder: Under an alcohol protective atmosphere, the raw materials weighed in step 1 were ball-milled at a low speed and dried to obtain a uniform mixed powder;

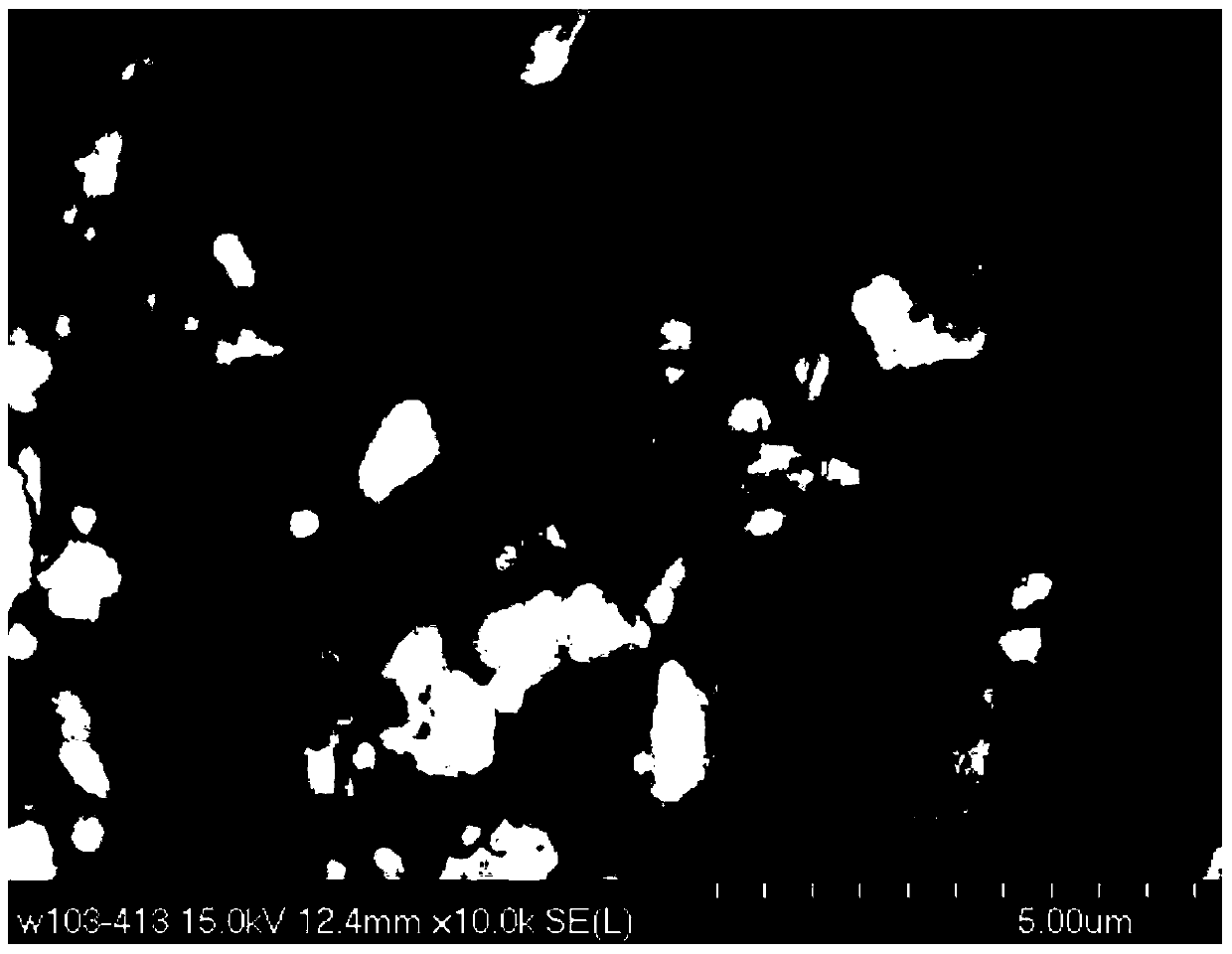

[0021] 3. Preparation of nanocomposite powder: Under the condition of argon protection, the uniformly mixed powder obtained in step 2 is subjected to high-speed ball milling to obtain a composite powder with a nanostructure;

[0022] 4. Preparation of high-density composite material block: After compacting the composite powder with nanostructure obtained in step 3 in a graphi...

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step one, by weight percentage, be 35.0% Nb, 2.5% Sn, 15.0% HA and the balance are Ti, take Nb powder, Sn powder, nano HA powder and Ti powder are used as raw materials. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com