A two-way prestressed concrete prefabricated hollow slab and its manufacturing method

A technology of hollow slabs and concrete, which is applied in the manufacture of tools, building structures, ceramic molding workshops, etc., can solve the problems of longitudinal splitting cracks, end crack hole walls, poor performance of shear force, etc., and achieve a reasonable structure. Rod, less exhaust gas and waste residue discharge, strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

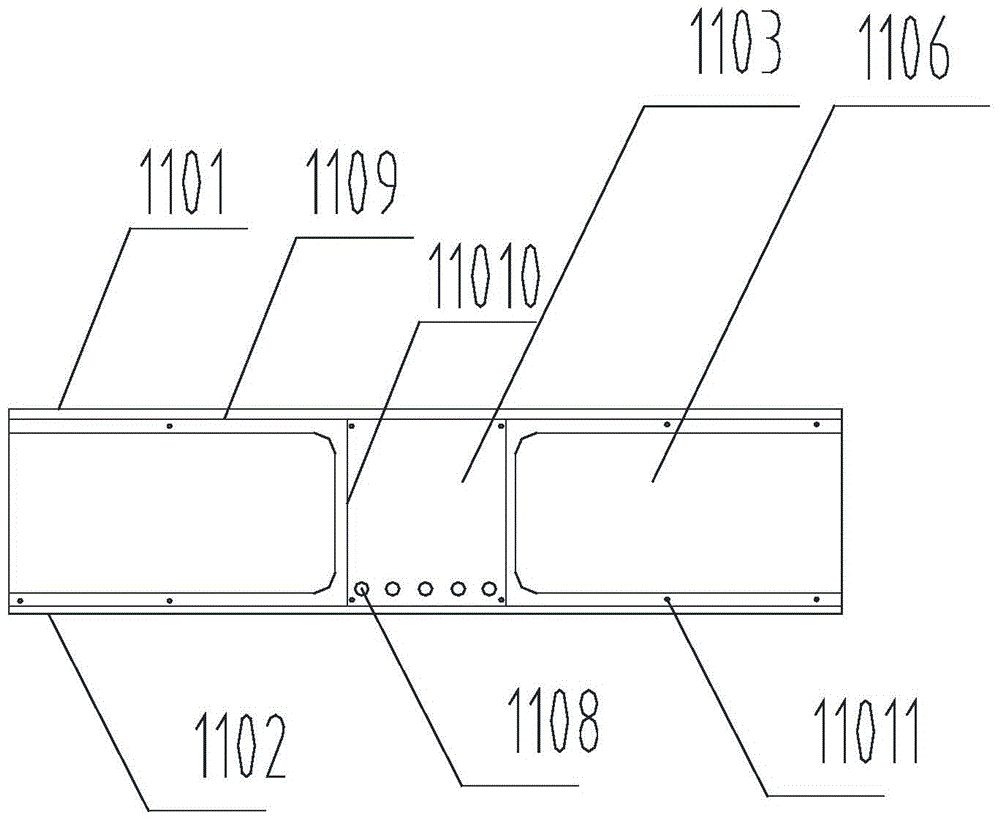

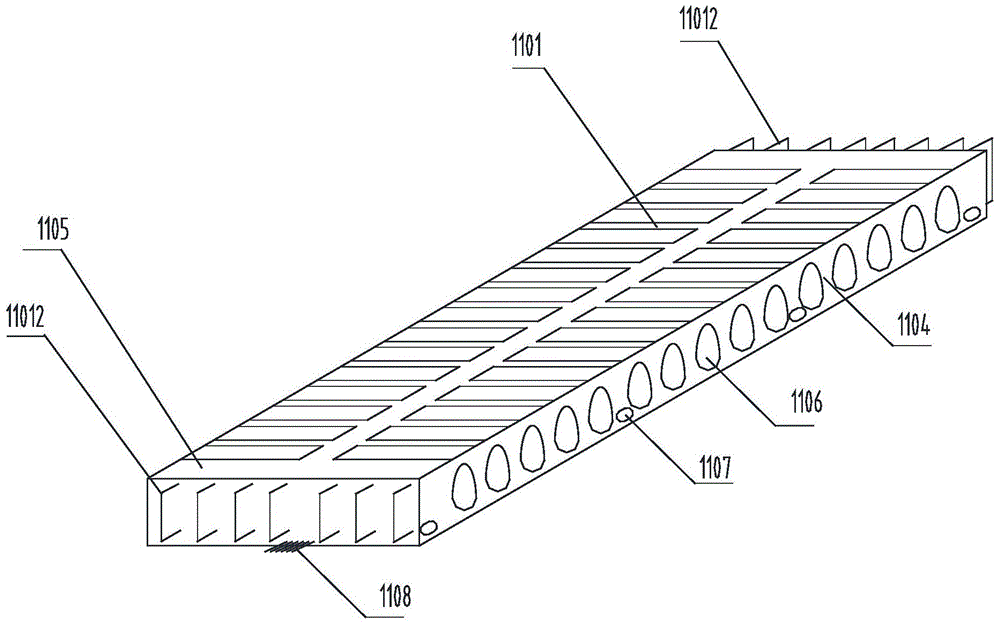

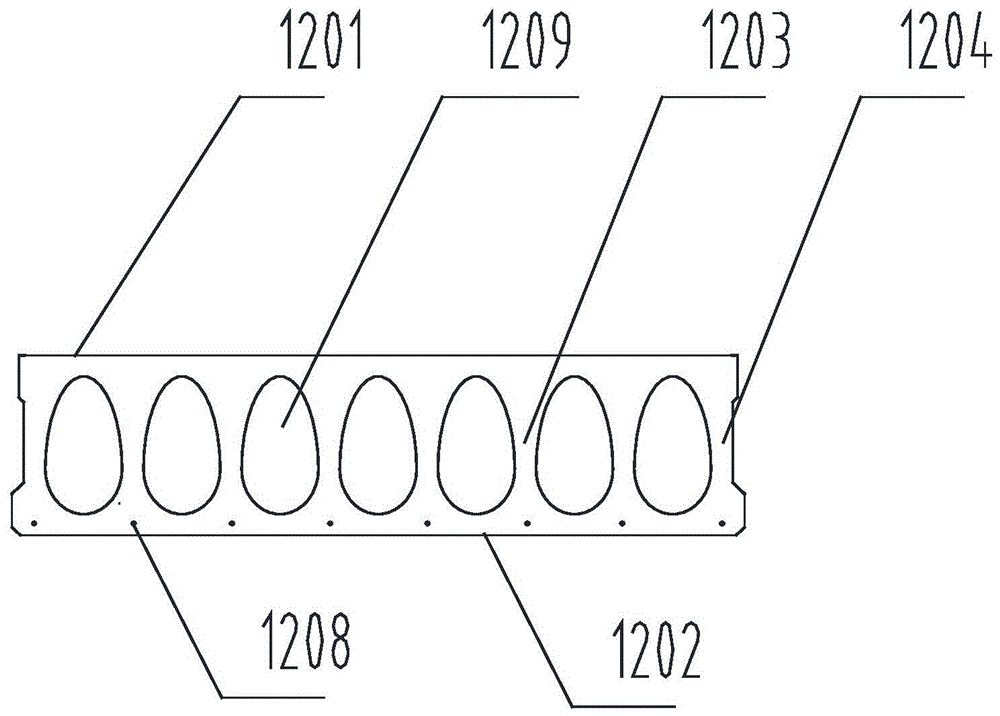

[0040] Such as Figure 1-11 As shown, a two-way prestressed concrete precast hollow slab includes a transverse hole prestressed concrete precast hollow slab 11 and a longitudinal hole prestressed concrete precast hollow slab 12. The transverse hole prestressed concrete prefabricated hollow slab 11 includes an upper panel 1101, a lower panel 1102, a longitudinal rib 1103, a transverse rib 1104, and an end rib 1105, and the transverse hole hollow slab is formed by pouring into one body. Holes 1106 are transversely provided on the hollow plate with transverse holes, and they are symmetrically and evenly arranged on both sides of the longitudinal rib 1103. In the transverse ribs 1104, a corrugated tube 1107 is provided with holes or buried in the transverse ribs every 1m to 2m. The longitudinal ribs 1103 have pre-stressed steel strands 1108 and a steel bar frame 11010. The upper panel has an upper steel wire mesh sheet 1109, the lower panel has a lower steel wire mesh sheet 11011,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com