Conveying belt type material drying machine

A conveyor belt and material technology, applied in the direction of dryers, drying, drying solid materials, etc., can solve the problems of uneven drying, incomplete drying, large floor space, etc., and achieve high drying efficiency and compact structure , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

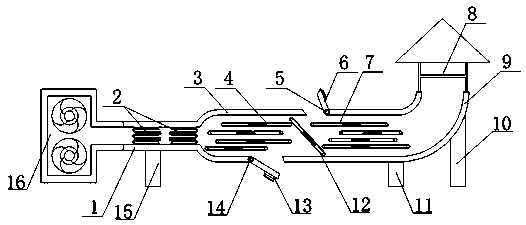

[0018] The present invention will be described below with reference to the drawings. figure 1 It is a schematic diagram of the structure of the present invention.

[0019] A conveyor belt type material drying machine of the present invention includes an air supply pipe 1, a drying chamber 3, a left conveyor belt 4, a right conveyor belt 7, an air outlet 9 and a rain cover 8, wherein the air supply pipe 1 is provided in the inner cavity There are heating wires 2, which are fixedly connected to the inner wall of the air supply pipe 1. The number of heating wires 2 are two groups and are electrically connected to an external power source. The lower part of the air supply pipe 1 is welded and fixed with an air supply pipe support 15 and an air supply pipe 1. One end is fixedly connected to the air box 16, and the other end is welded and fixed with a drying chamber 3, the upper middle of the drying chamber 3 is provided with a feed door hinge 5, and a feed door 6 is provided on the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com