A remote phosphor performance testing device and testing method

A remote phosphor and testing method technology, applied in the field of remote phosphor performance testing devices, can solve problems that affect the accuracy of phosphor testing, do not consider the impact of phosphor film light transmission, and cannot truly reflect the characteristics of remote phosphors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

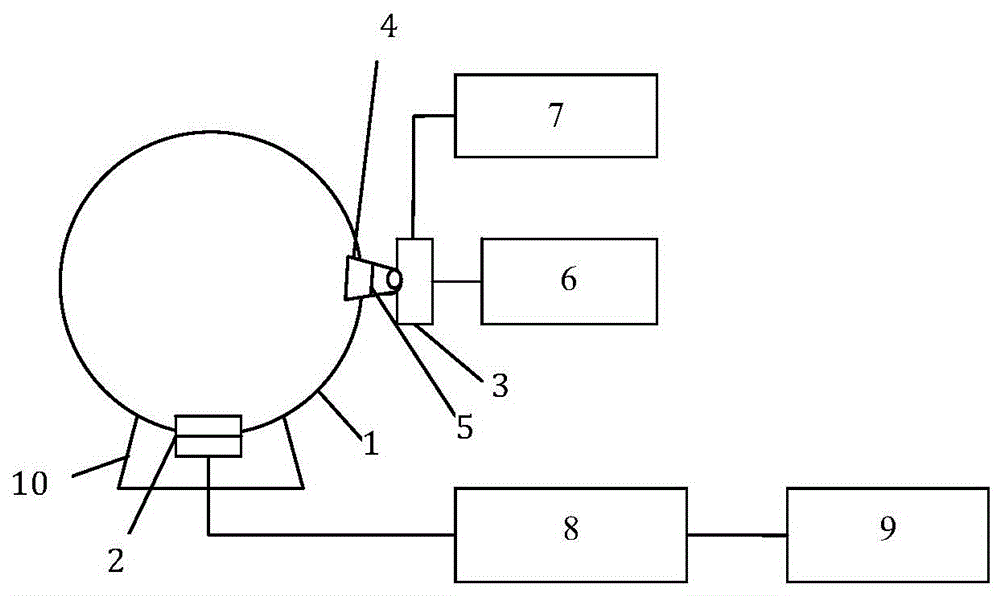

[0026] see figure 1 , The embodiment of the remote phosphor performance testing device is provided with an integrating sphere 1, a cosine collector 2, a blue LED light source 3, a reflective cup 4, a phosphor sheet / silica gel sheet 5, a TEC temperature control fixture 6, a constant current source 7, and a spectrometer 8 , a computer 9 and a base 10; the integrating sphere 1 is fixed on the base 10, the integrating sphere 1 is provided with a light entrance and a light exit, and the cosine collector 2 is connected to the spectrometer 8 by an optical fiber at the light exit for collecting incident light, The output terminal of the spectrometer 8 is connected to the computer 9 for spectrum acquisition and data analysis; the blue LED light source 3 is connected to the constant current source 7, and is fixed on the TEC temperature control fixture 6 as an excitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com