A heavy ion microporous membrane etching device

A heavy-ion microporous film and etching device technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high labor intensity, reduced winding pass rate, film breakage, etc., and achieve high temperature control accuracy. , Reduce the labor intensity, and the effect of rolling the edges neatly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

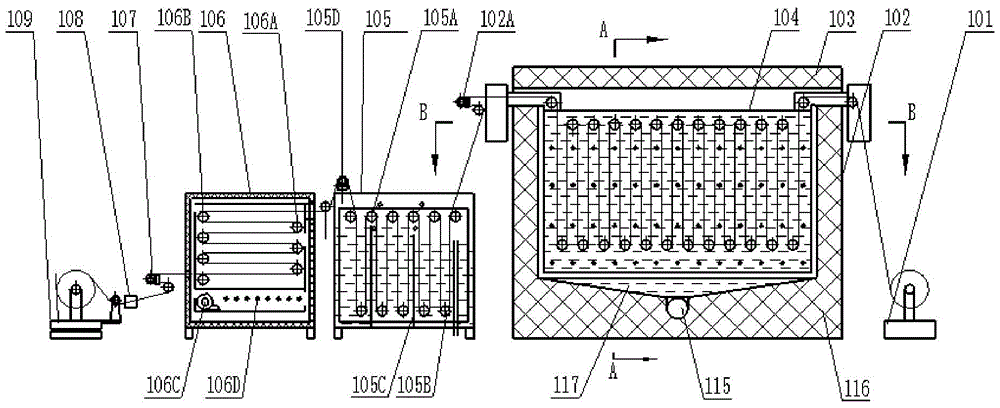

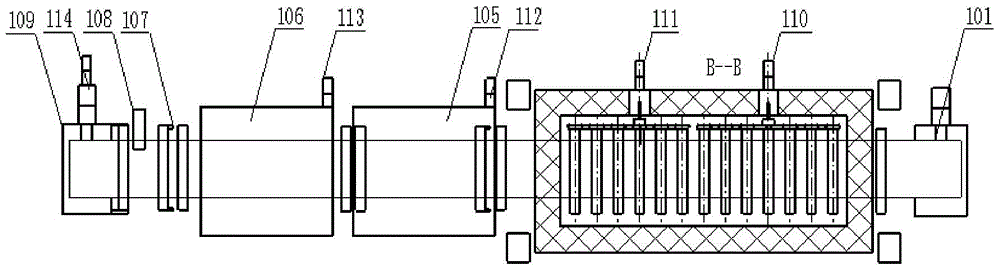

[0071] see Figure 1a and Figure 1b A heavy ion microporous membrane etching device provided in Embodiment 1 of the present invention includes an unwinding device 101, an etching box 102, a cleaning box 105, a drying box 106, a winding device 109 and a heavy ion microporous membrane etching device arranged in sequence. The control system of the hole film etching device;

[0072] Wherein, the control system includes a PLC control system and an HMI human-computer interaction device electrically connected to the PLC control system;

[0073] The etching box 102 includes a box body and a shaft support device arranged in the box body; The pedestal structure described in , the two can be replaced by each other);

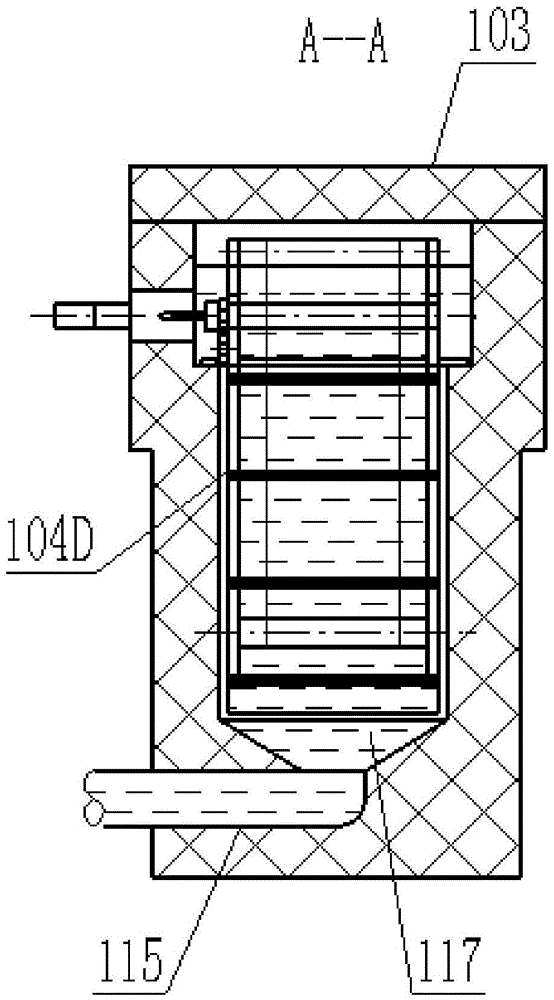

[0074] see image 3 , the shaft support device is in the etching liquid, the top is fixed with a plurality of transmission shafts 104A, and the bottom of the shaft support device is fixed with a plurality of follower shafts 104E; the drive shaft 104A and the follower s...

Embodiment 2

[0116] Figure 5 Shown is another etching box 202 provided by Embodiment 2 of the present invention. Except for the installation of the heater and the installation of the lower follower shaft, the structure is the same as that of the etching box 102 shown in FIG. 1 , and its functions and functions are consistent. . Wherein, the shaft support device is a shaft frame 205; each shaft frame 205 is composed of a top beam and two ladder frames, and the bottoms of the two ladder frames are respectively equipped with the follower shaft 205A and the follower shaft 205B. A transmission shaft 207 is arranged in the space between the two ladder frames and below the top beam. The stainless steel pipe 204A is sealed and welded to the box body, and is socketed with the heater 204 . And adopt to directly weld the stainless steel pipe 204A in the etching box body, the stainless steel pipe 204A and the box body are sealed and welded, and then penetrate the heater 204, and the power lead wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com