Method for improving PERC (passivated emitter rear contact) battery back slotting contact

A back and battery technology, applied in the field of solar cells, can solve problems such as thermal damage, reduced minority carrier life, and poor battery performance, and achieve the effects of reducing production costs, improving matching, and reducing fragmentation rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

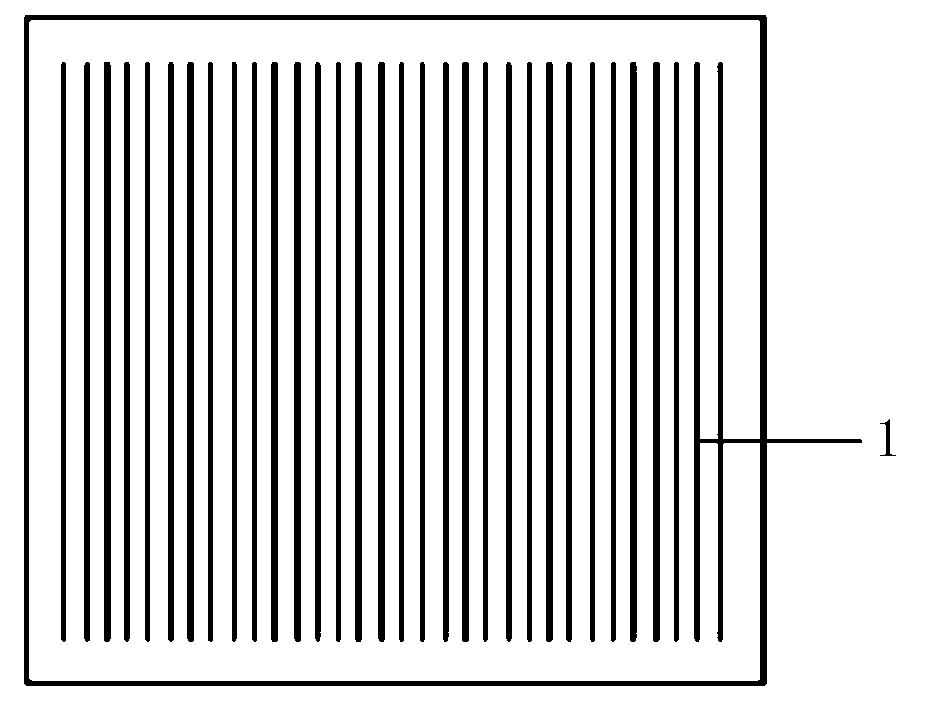

[0010] as attached figure 1 Shown is a method for improving PERC battery back slot contact, including silicon wafer polishing, texturing, diffusion, edge removal and PSG removal, double-sided passivation, screen printing electrodes and sintering steps in sequence, characterized in that : After the step of de-edge junction and PSG removal, the step of screen-printing Al paste on the back and forming a grid-shaped aluminum back field is added, and after the silicon wafer prepared with a grid-shaped aluminum back field is passivated, the back electrode is printed on the back The busbar burns through the passivation layer so as to be in contact with the grid line-shaped aluminum back field, which can fully collect carriers and save the back slotting step after the conventional double-sided passivation step; the grid line-shaped aluminum back field is composed of It consists of a number of neatly arranged thin grid lines 1 . The side length of the grid-shaped aluminum back field i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com