Method for improving p-type ohmic contact performance of GaN-based light-emitting device

A technology for ohmic contact and light-emitting devices, applied in semiconductor devices, electrical components, circuits, etc., can solve the difficulty of increasing p-type ohmic contacts, the difficulty of high-concentration doping of p-type GaN materials, and the ohmic contacts of p-type GaN materials need to be further improved Improvement and other issues, to achieve excellent ohmic contact characteristics, reduce the effect of height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments, but the scope of protection of the present invention is not limited to this. If there are processes that are not specifically described below, all Those skilled in the art can refer to the prior art.

[0022] A method for improving the ohmic contact performance of p-type GaN material in this embodiment includes the following steps:

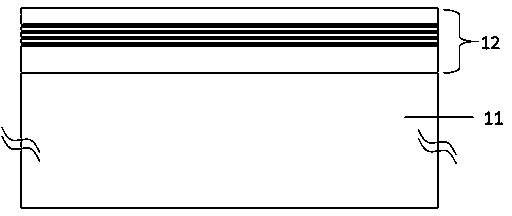

[0023] 1. Provide a GaN-based light-emitting epitaxial layer with sapphire as the base, and activate p-type GaN;

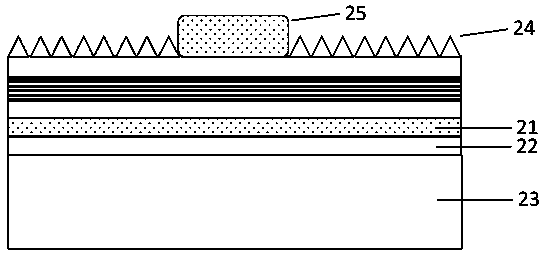

[0024] 2. Clean and process the sample, and make an indium tin oxide (ITO) layer with a thickness of 100 nm to 300 nm on the p-type GaN side;

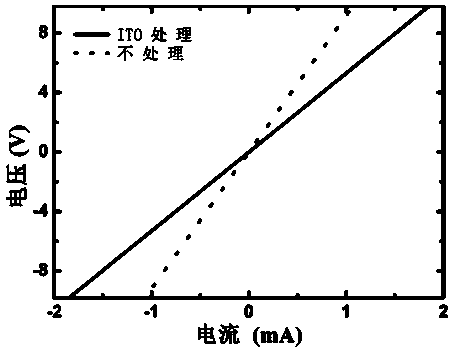

[0025] 3. In a nitrogen environment, the sample is annealed, the annealing temperature is constant between 450°C and 550°C, and the annealing time is 1 minute to 15 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com