Interface transition layer composite structure used for P-SiC ohmic contact and preparation method thereof

A composite structure and transition layer technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low specific contact resistivity and difficult ohmic contact of P-type SiC materials, so as to reduce the impact and avoid The influence of tunneling mechanism and the effect of increasing carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

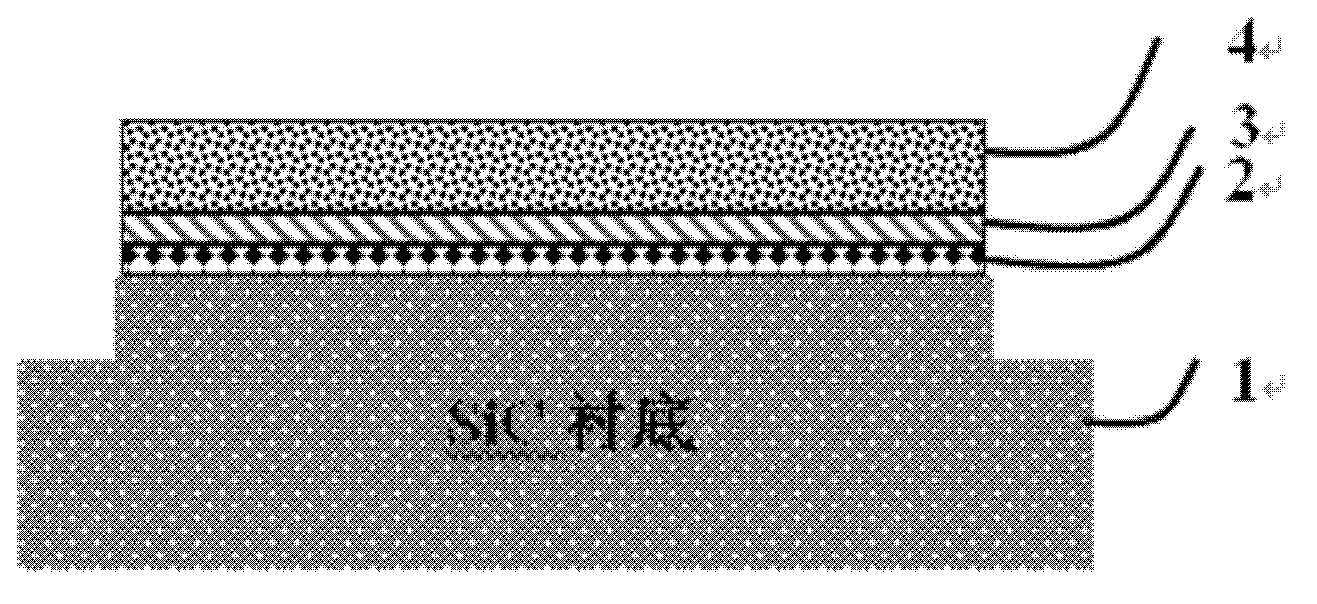

[0062] 1) Interfacial transition layer composite structure. Through the analysis of the energy band model of the composite structure of the interfacial transition layer, the selected composite structure is Al-rich layer plus Ti 3 SiC 2 carbide structure.

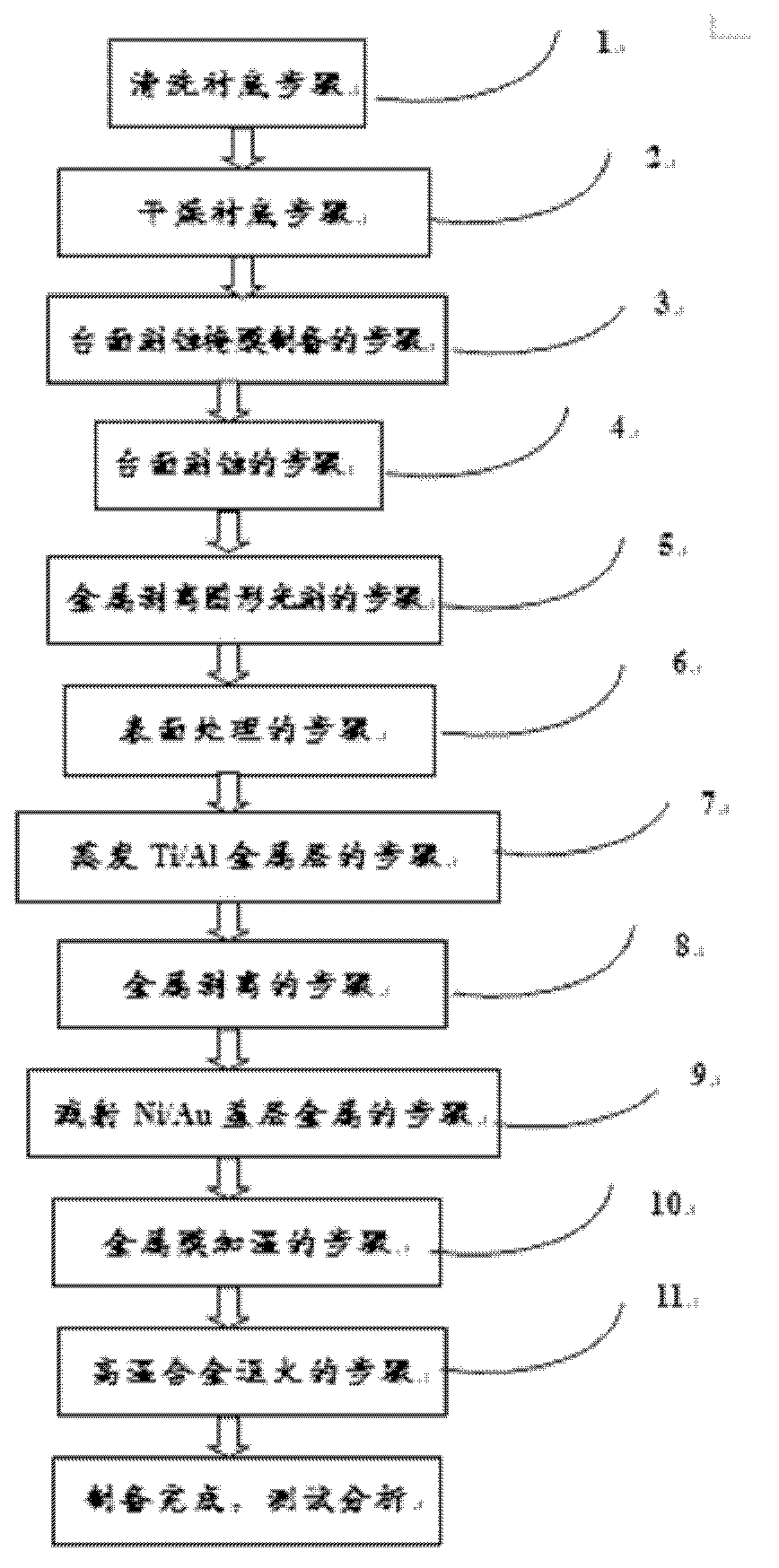

[0063] 2) The preparation process of the interfacial transition layer composite structure.

[0064] The main steps include: for ion implantation with a maximum energy of 550Kev (the thickness of the P-type implantation layer is about 0.7um) to activate the sample at high temperature, perform strict cleaning steps, and dry it in an oven at 120°C for 10 minutes; use 9920 photoresist , 2000rpm, produced a 3.1um thick photoresist as a mask for mesa etching; used ICP etching for 400s, and the mesa etching depth was about 0.8um; using AZ5214E photoresist, produced a photoresist with a thickness of about 2.2um Peel off layer; using HF:H 2 The solution of O(1:10) corrodes about 30sec, N 2 Blow dry fully; use an evaporation ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com