High temperature pressure sensor technology based on heavy doping 4H-SiC substrate

A pressure sensor and heavy doping technology, which is applied to the measurement of the property and force of piezoelectric resistance materials, electric solid-state devices, semiconductor devices, etc., and can solve the problems of incomplete varieties and low output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

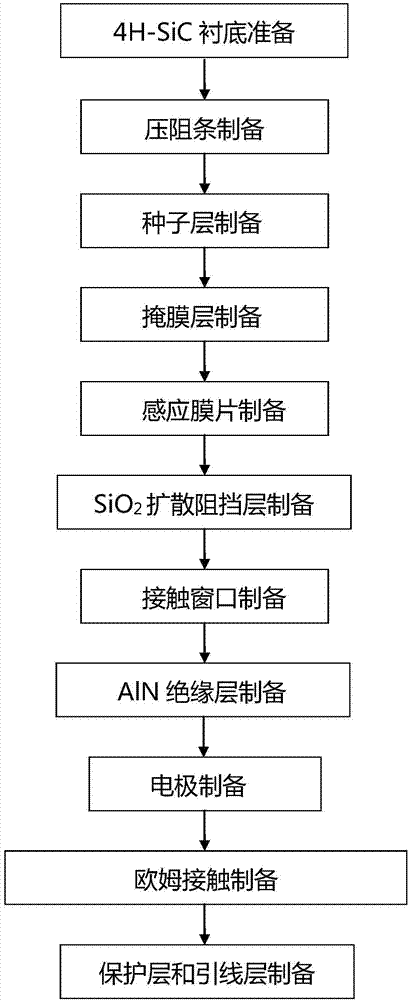

[0008] A kind of preparation process of the high-temperature pressure sensor based on heavily doped 4H-SiC substrate described in the present invention, especially n-type heavily doped 4H-SiC substrate (such as figure 1 shown), including the following steps:

[0009] Step 1, preparing a 4H-SiC substrate: the substrate is a SiC wafer, polished on both sides, and cleaned by RCA.

[0010] Step 2, preparation of piezoresistive strips: pattern the substrate by photolithography, magnetron sputtering Ni, peel off the photoresist to realize pattern transfer, RIE (reactive ion etching) shallow etching of 2 μm, soak in Ni corrosion solution 10min, rinse with deionized water, N 2 blow dry.

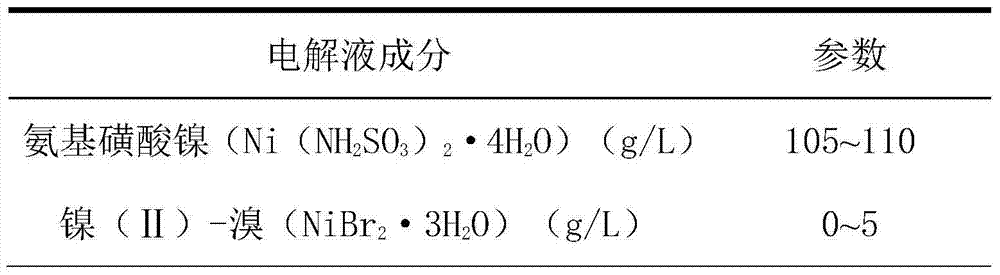

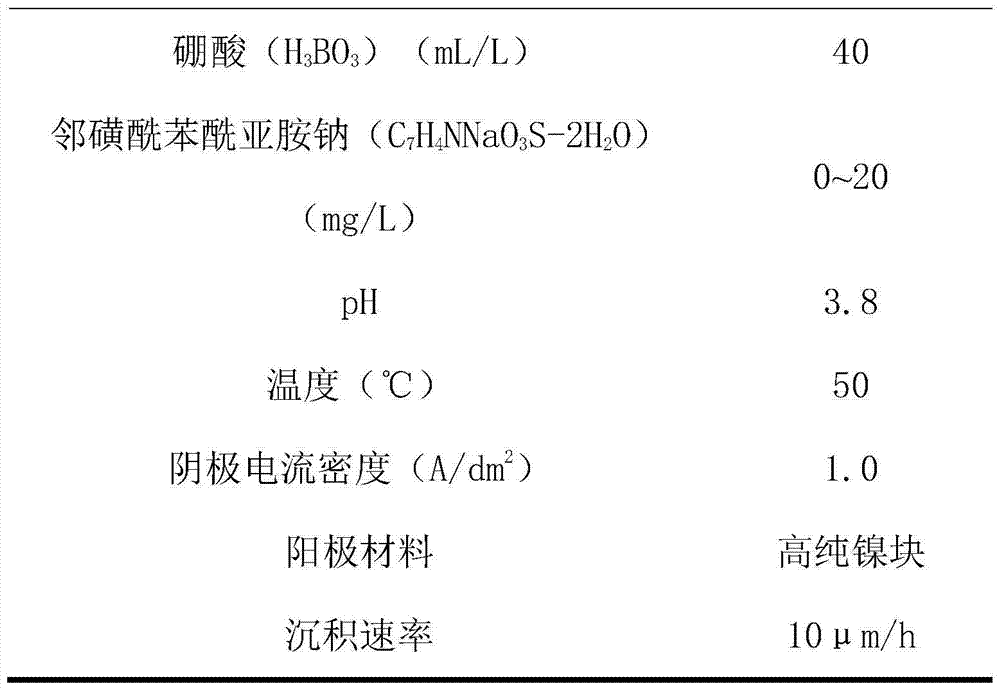

[0011] Step 3, prepare the seed layer: use photolithography to pattern the substrate, use ultra-high vacuum magnetron sputtering equipment, radio frequency target position, 75W, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com