Laminated ceramic capacitor

A technology of ceramic capacitors and laminates, applied in the direction of multilayer capacitors, capacitors, fixed capacitors, etc., can solve the problem that capacitors cannot obtain capacity, and achieve the effect of improving high-density stacking and ensuring grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

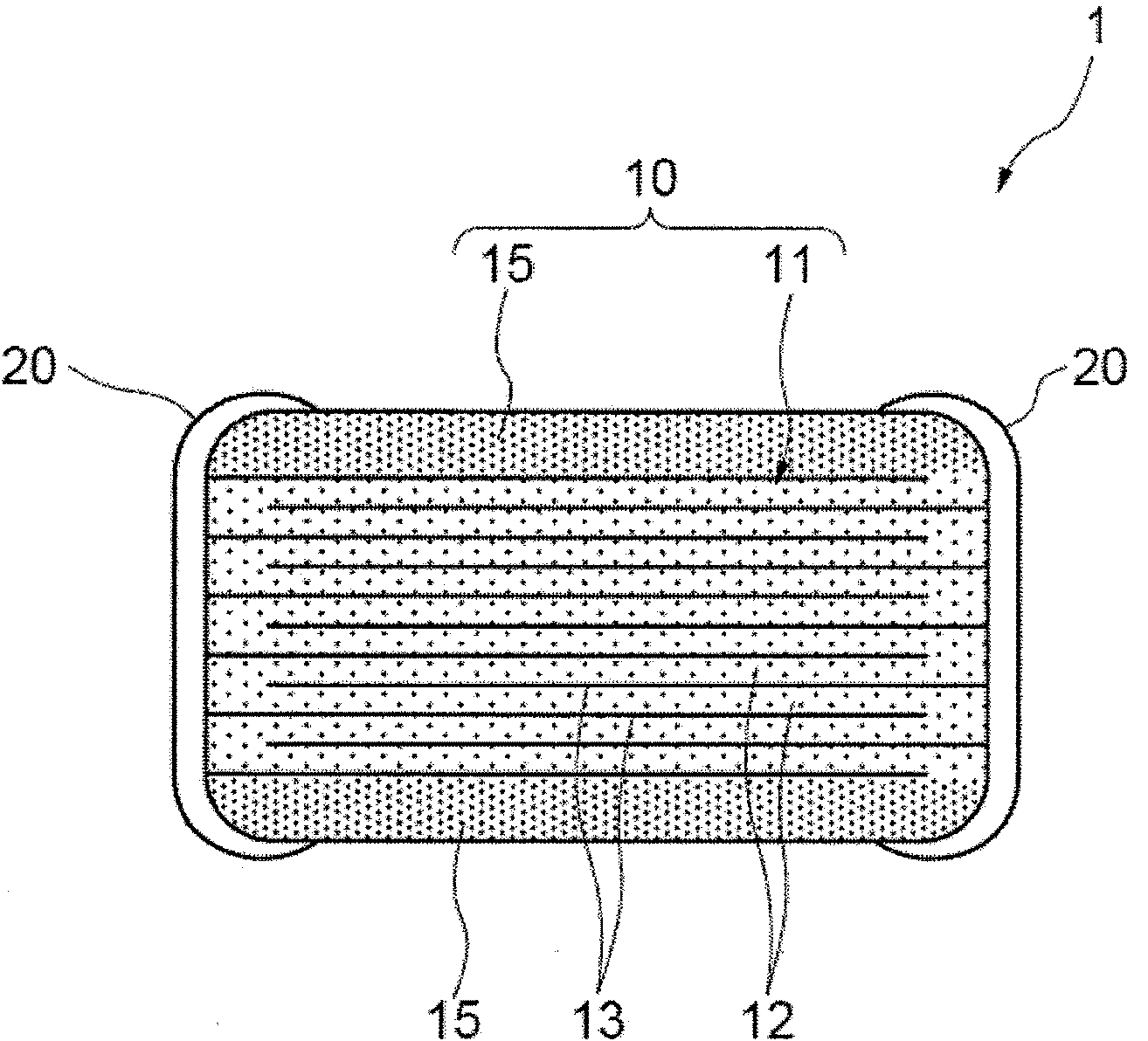

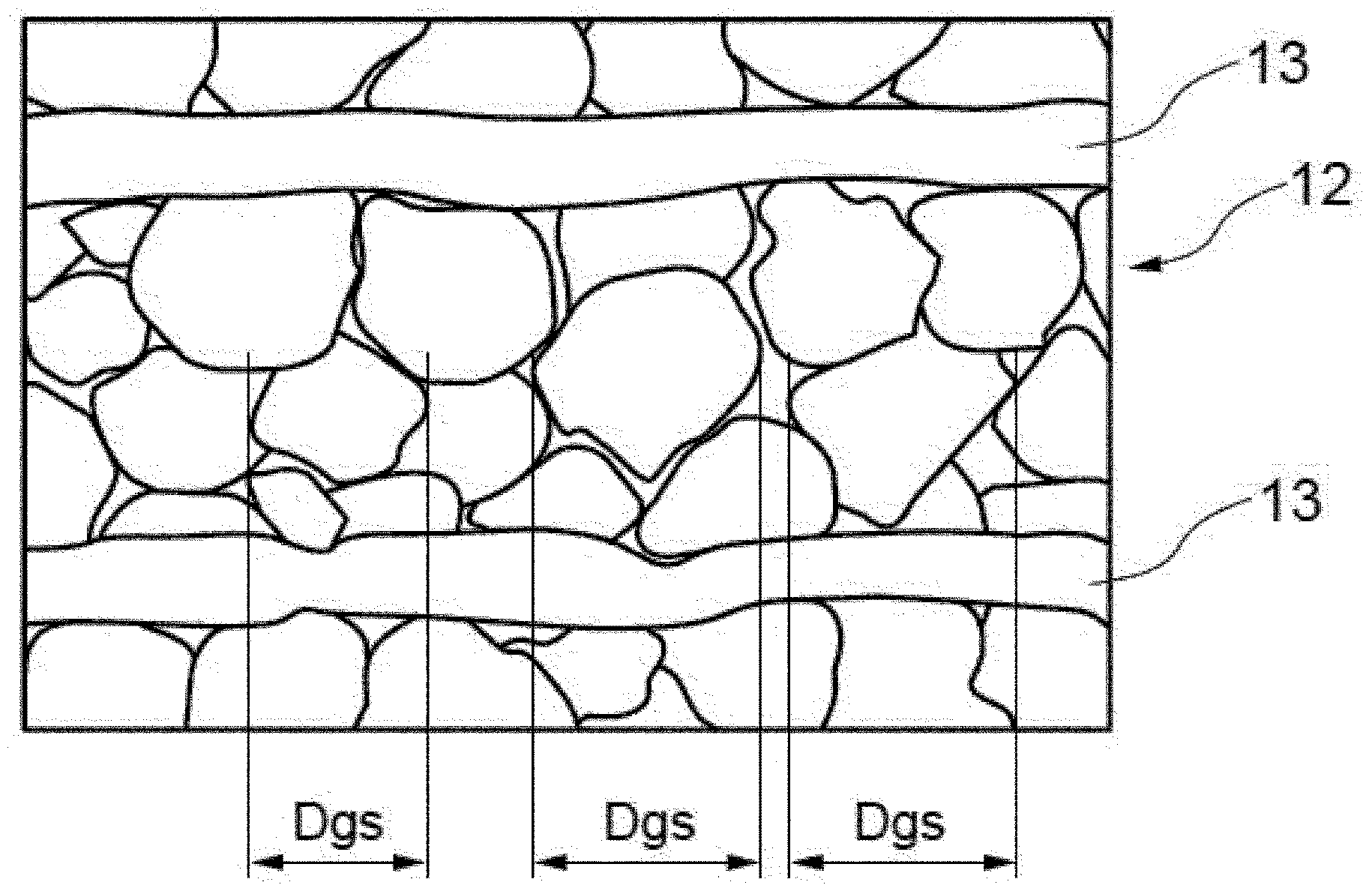

[0038] Next, examples of the multilayer ceramic capacitor (hereinafter referred to as "MLCC") of the present invention will be described.

[0039]

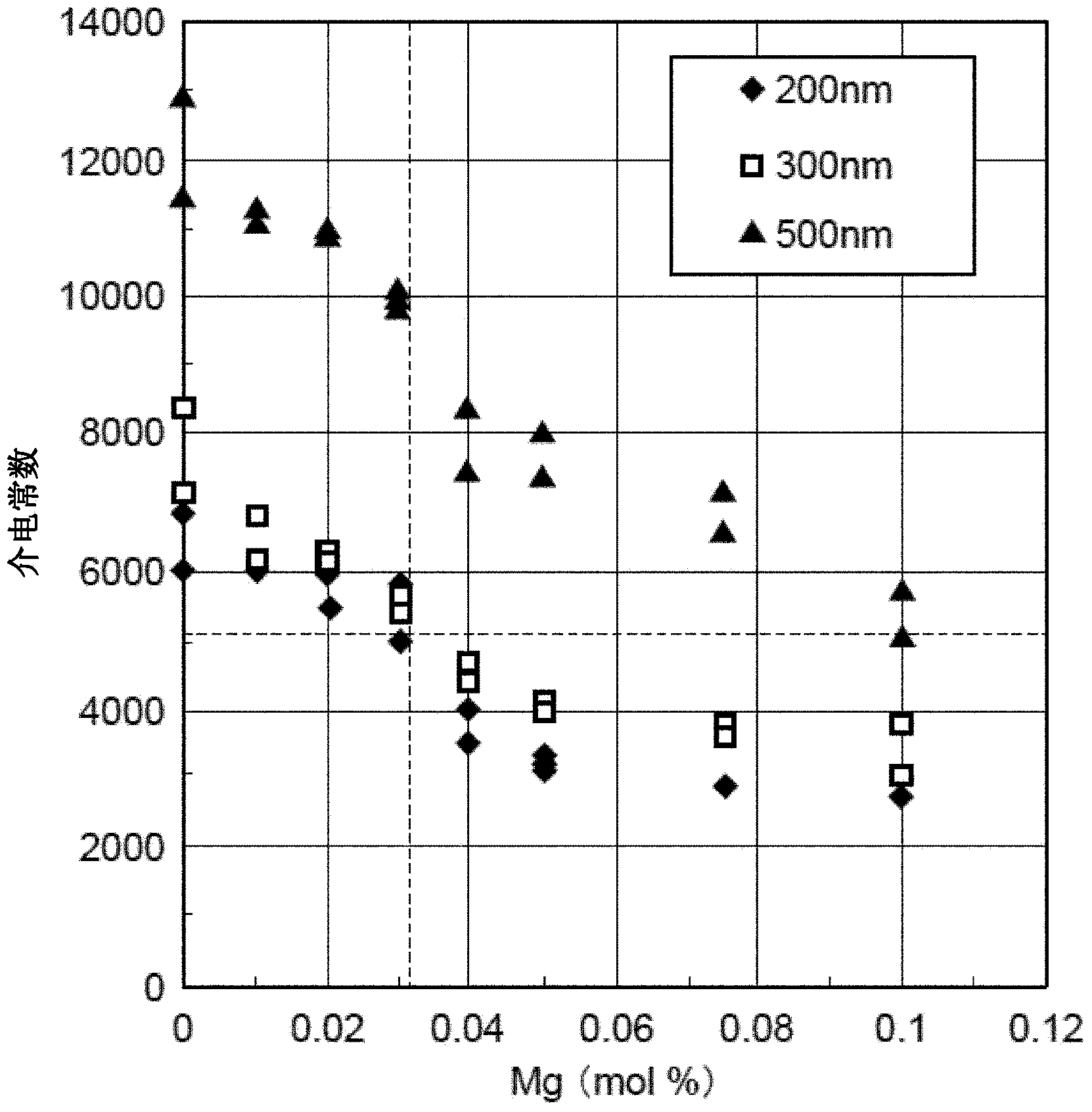

[0040] (1) Preparation of dielectric raw material powder

[0041] First, as the raw material powder of the dielectric, high-purity BaTiO with an average particle size of 110 nm 3 Powder, ReO shown in Tables 1 to 7 3 / 2 , SiO 2 , MO X (to be used as MnCO 3 ; by roasting CO 2 Separation into MnO), ZrO 2 Each compound of MgO and MgO is prepared as a raw material powder for a dielectric. The average particle diameter of the raw material powder was obtained by observing the powder samples of barium titanate with SEM, the number of samples was 500, and the median particle diameter was taken. Next, the respective compounds were weighed and mixed so that the composition ratio of the dielectric layer of the MLCC, that is, the sintered body became the composition ratio shown in Tables 1-7. The raw material powders of the respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com