Flow dividing type filter device

A filtration device, the technology of split flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

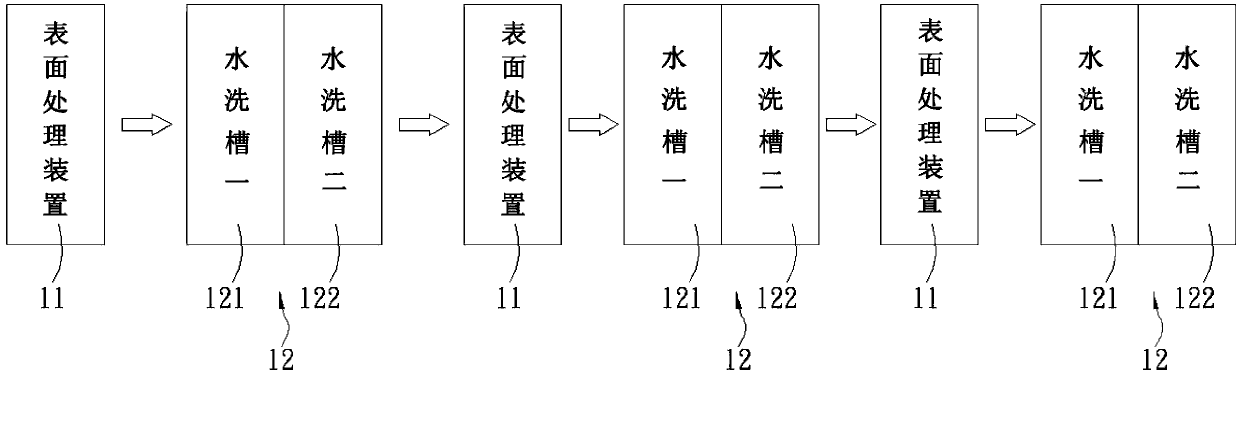

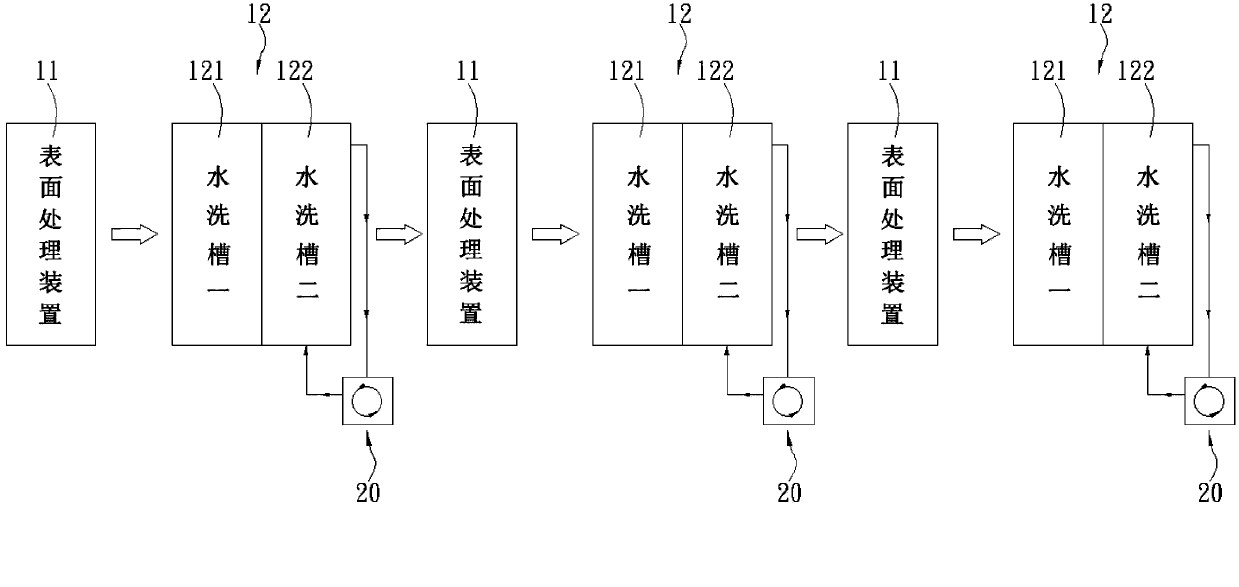

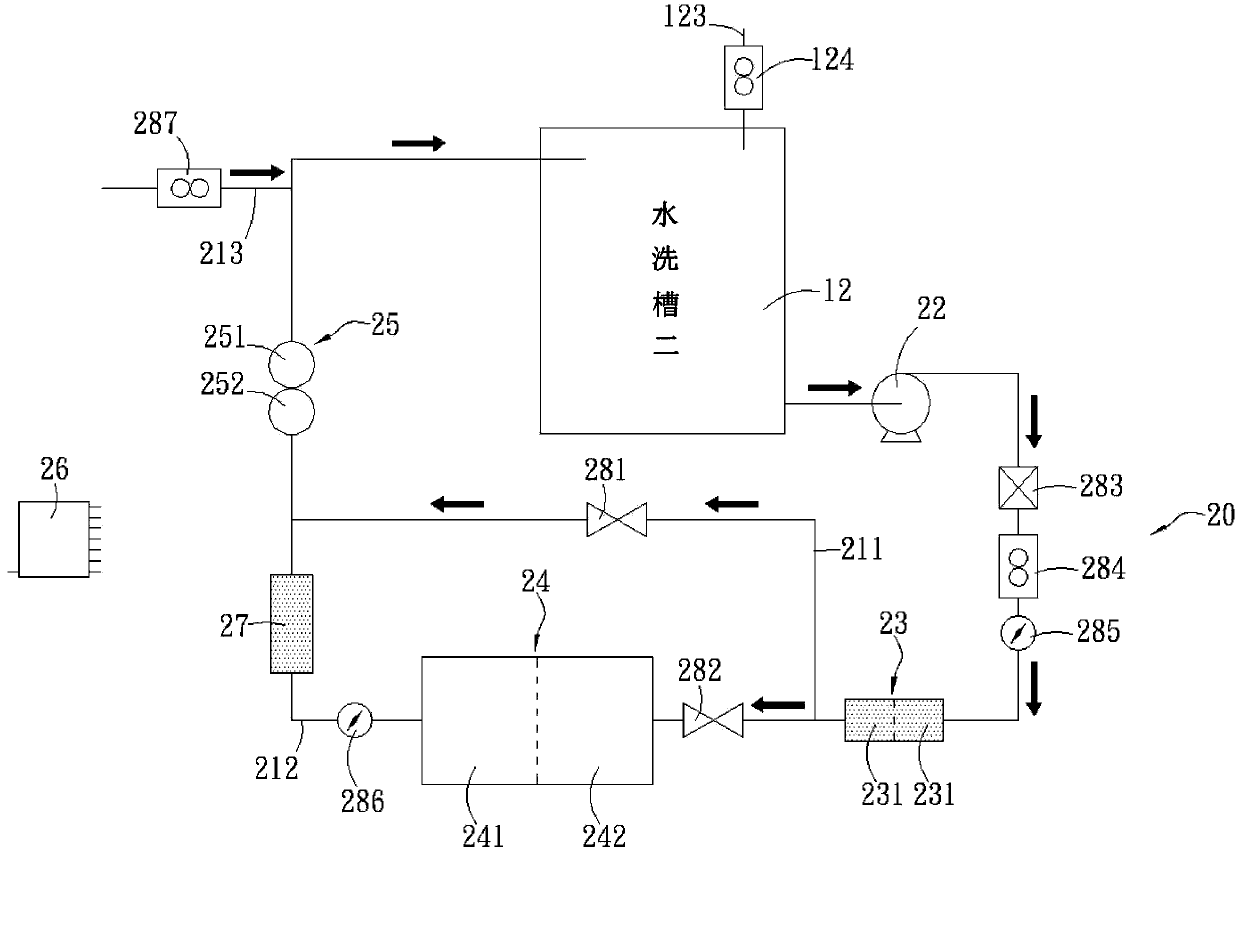

[0051] Such as figure 1 As shown, the split-flow filter device 20 of the present invention can be widely used in the processing process. It can be connected to the washing tank 12 provided at the rear of the surface treatment device 11 to produce a real-time circulating filtering effect on the water in the washing tank 12. Please also refer to figure 2 As shown, the split-flow filter device of the present invention basically includes: a set of return water pipelines 211, a pressure pump 22, a pre-filter module 23, a component flow pipeline 212, and at least one water quality adjustment module 24. A water quality detection module 25 and a control circuit 26; wherein: the head and tail ends of the set of return water pipelines 211 are connected to the applied washing tank 12, and a middle section of the entire set of return pipelines 211 is provided The first valve 281 that controls whether the associated pipeline is on or off.

[0052] The pressurizing pump 22 is set at a predete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com