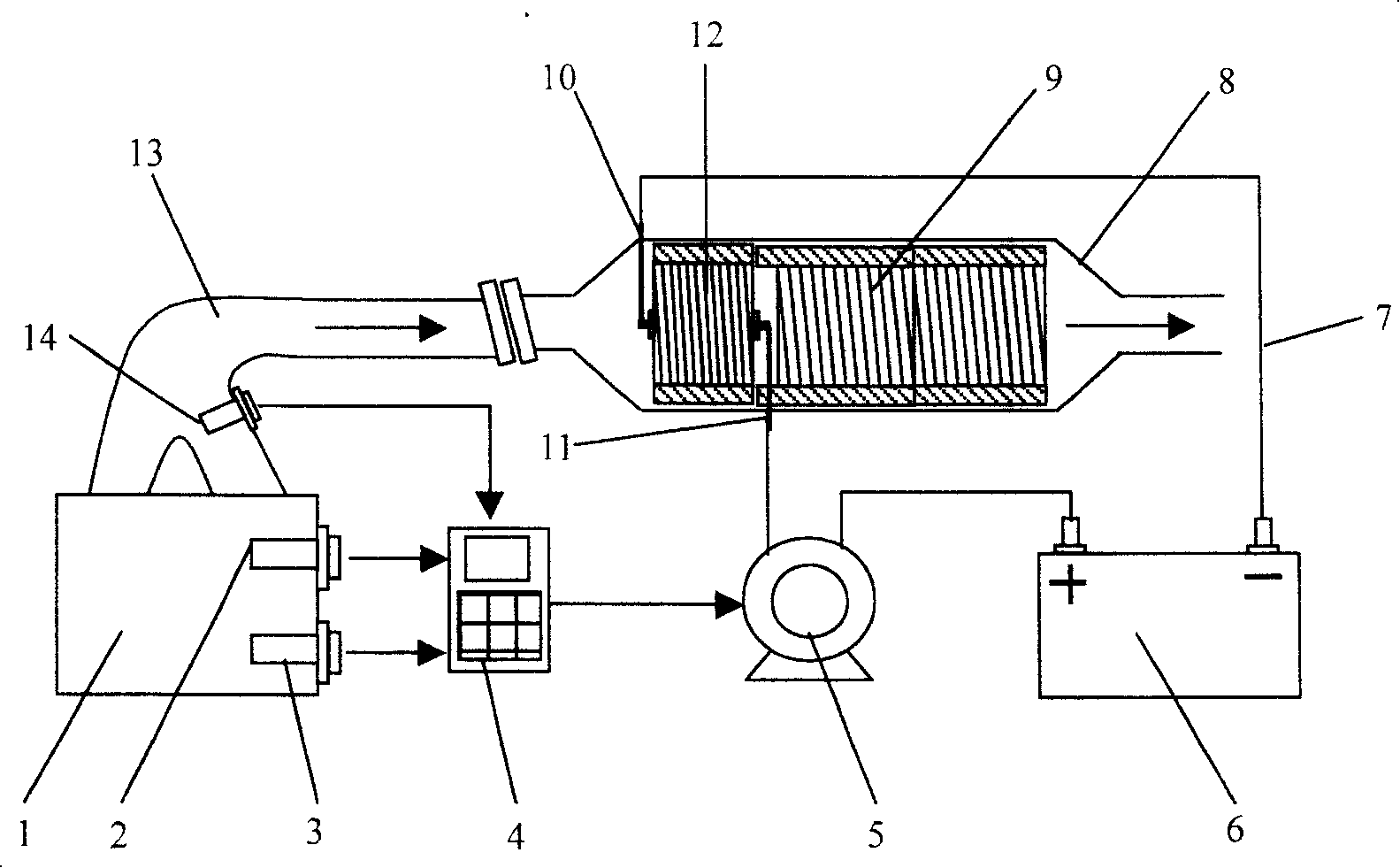

Spiral type filtering-regeneration device for particulates in exhaust gas from diesel vehicle

A technology of regeneration device and particle filter, which is applied to exhaust device, muffler device, engine components, etc., can solve the problems of particle filter melting and explosion, and achieves the effect of easy assembly, long service life and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

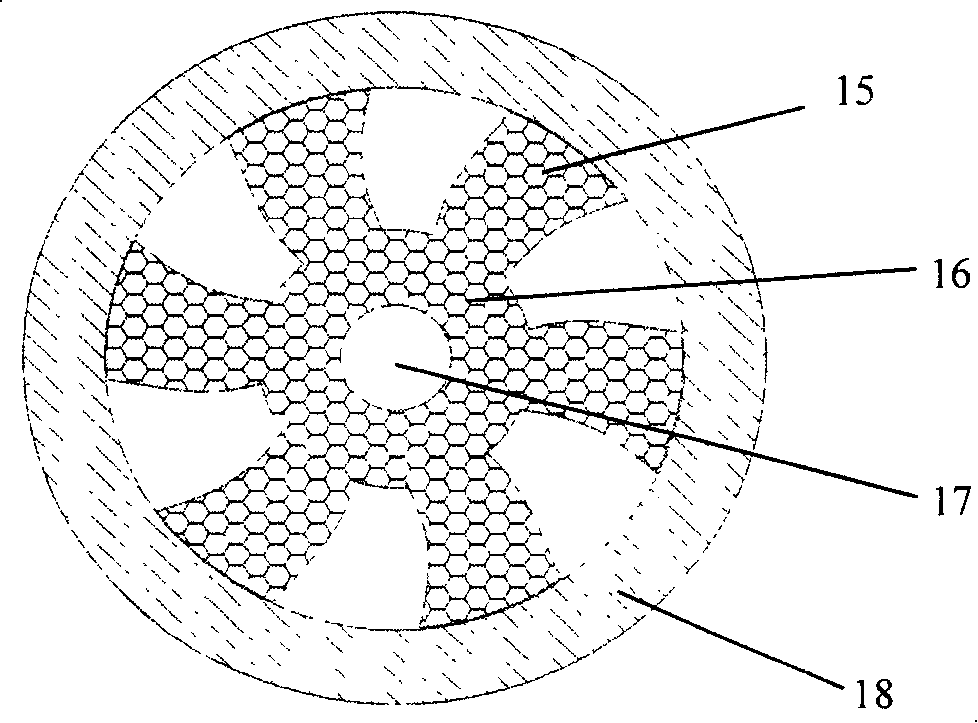

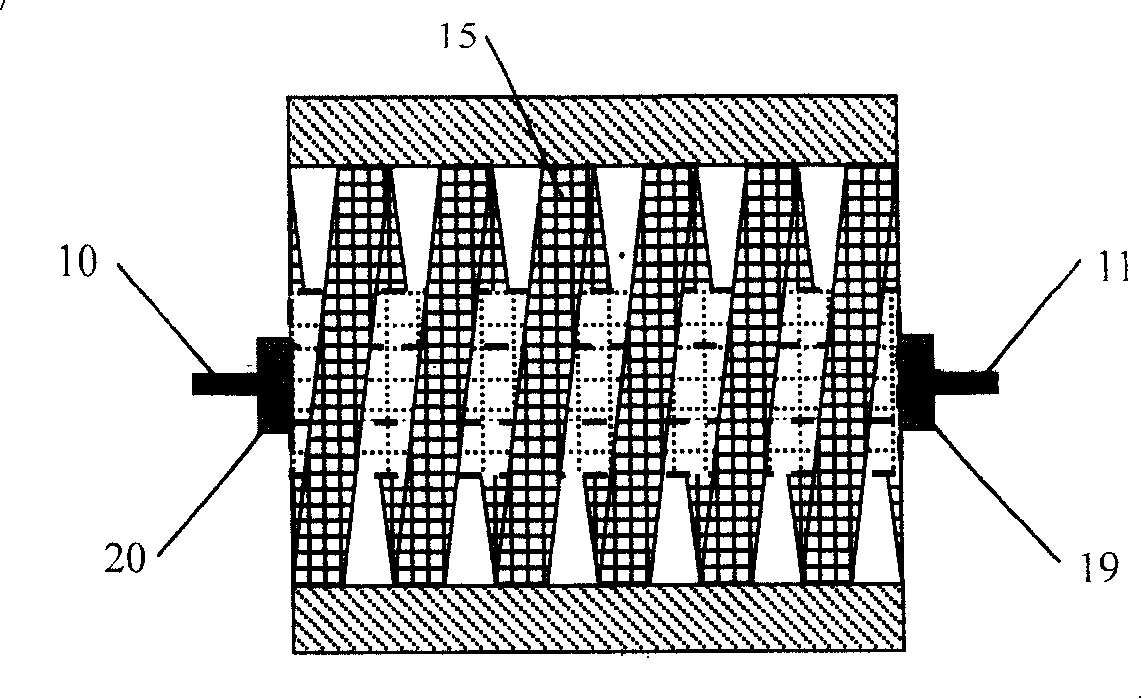

[0045] ①Machining silicon carbide foam ceramics with a volume fraction of 30% and an average foam pore diameter of 1mm into a helical structure with six helical blades, the outer diameter of the helix is φ140mm, the helix depth is 50mm, the thickness of the blades is 10mm, the distance between the blades is 10mm, and the lead is 120mm , Center hole φ10mm.

[0046] ② Machining tubular silicon carbide foam ceramics with an outer diameter of φ180mm and an inner diameter of φ140mm.

[0047] ③ Put the tubular silicon carbide foam ceramic obtained in ② on the periphery of the spiral structure obtained in ①, and bond the two firmly with ethyl silicate to obtain a spiral turbulent particle filter. There are two dimensions: φ180mm×100mm and φ180mm×250mm. The former can have electric heating function after welding electrodes.

[0048] ④ On the silicon carbide ceramic electrode bases at both ends of the φ180mm×100mm spiral turbulent particulate filter mentioned in ③, weld a stainless ...

Embodiment 2

[0052] The difference from Example 1 is:

[0053] Before the test, the spiral diesel vehicle exhaust particulate filter-regeneration device was installed at the designated position of the diesel engine exhaust passage, and the engine speed was kept at 2160rpm, the torque was 188Nm, and the power was 42.5kW for 5 hours to make the spiral diesel vehicle exhaust particulates The filter-regeneration device fully accumulates soot, and then connects the electric heating circuit for electric heating regeneration. Carry out the 13 working condition tests with embodiment 1 again after regeneration.

Embodiment 3

[0055] The difference from Example 1 is:

[0056] The volume fraction of silicon carbide foam ceramics constituting the spiral turbulent particle filter is 40%, and the average pore diameter is 1.0mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com