Special wrench for high-voltage line inspection robot operation

A technology for inspecting robots and high-voltage lines, which is applied in the direction of wrenches, hand-held tools, wrenches, etc., can solve the problems of lack of dexterity of the end effector of the operating arm, difficulty in using ordinary wrenches, and difficulty in direct operation of the operating arm, etc., to achieve convenience for robots Effects of operation, reduced range of motion, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

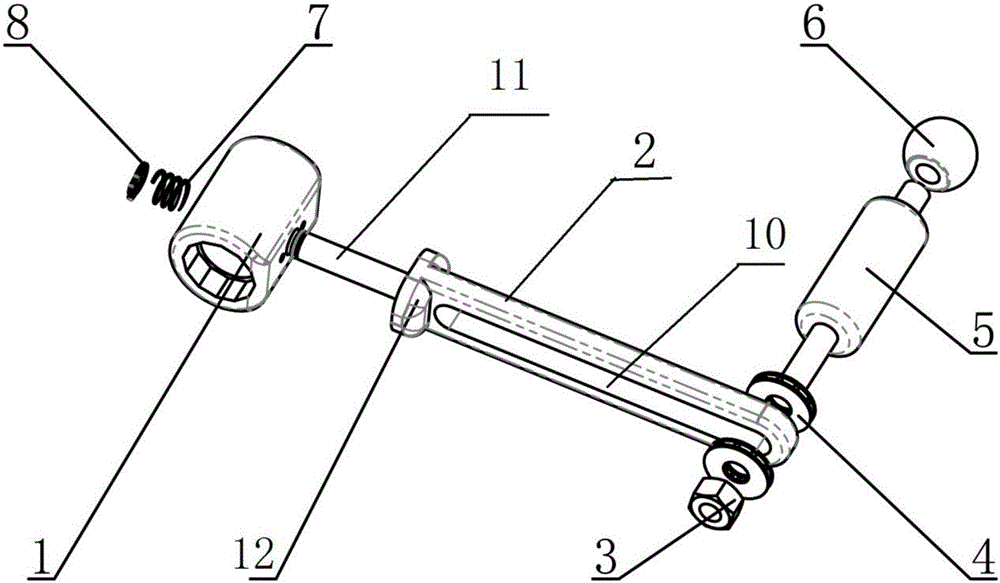

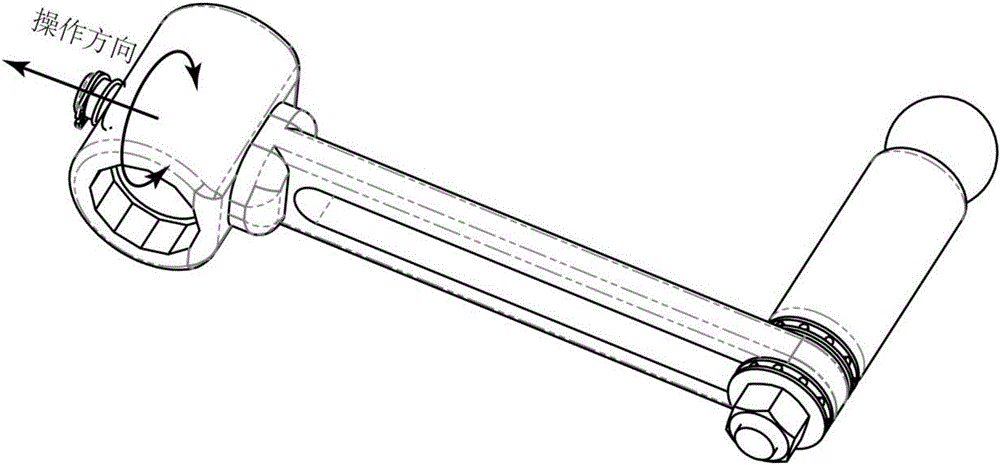

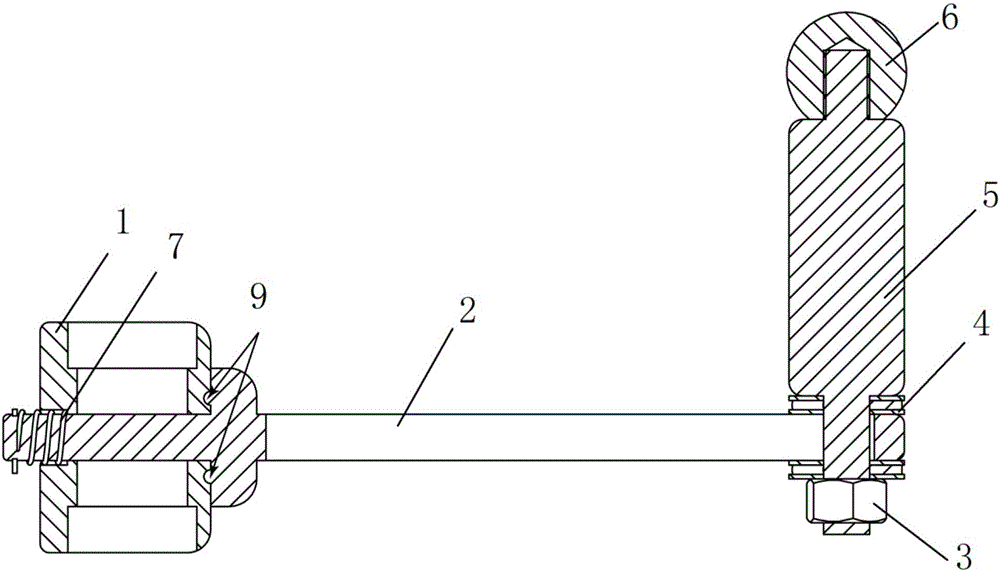

[0035] like figure 1 The exploded view of the special wrench is shown, and the parts include wrench head 1, wrench arm 2, handle 5, handle ball 6, thrust needle roller bearing 4, etc. The handle ball 6 is a spherical body provided with threaded holes along its radial direction, and the threaded holes are blind threaded holes. The handle ball 6 is fixed on the handle 5 through threads, the handle 5 is fixed on the chute 10 of the wrench arm 2 through the thrust needle roller bearing 4 and the nut 3, the wrench head 1 is pressed on the wrench arm 2 through the compression spring 7, and the wrench as a whole is Zigzag.

[0036] There is a chute 10 on the wrench arm 2 along its length direction, and the chute 10 is a transparent elongated groove along the front and back sides of the wrench arm 2 length direction. The handle 5 is installed in the chute 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com