Colorful crystal glass compounded with plate layer

A technology of colored crystal glass and plate, applied in the direction of synthetic resin layered products, glass/slag layered products, layered products, etc., can solve the problems of color film bubbles around the glass, lower product yield, lower product quality, etc. Achieve strong adhesion, improve quality, and resist ultraviolet radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

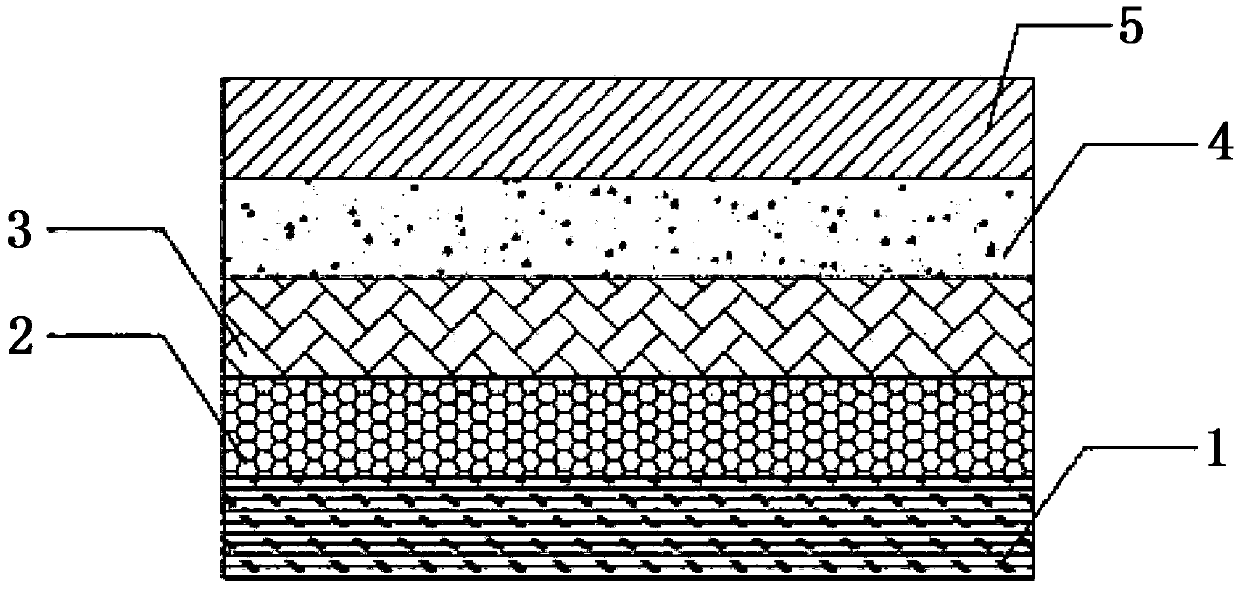

[0023] Such as figure 1 As shown, it is a color crystal glass compounded with a sheet material layer in accordance with the present invention, including a glass layer 1, and a first glue layer 2, a color filter layer 3, and a second glue layer 4 are sequentially arranged on the glass layer 1 and sheet layer 5. Because the contact surface is the plate layer 5, it is no longer the direct contact between the traditional glass and the foam material, so that the pulling force of the foam material during shrinkage can be effectively blocked in the subsequent production process, and there will be no bubbles in the color film around the glass. , thereby improving the quality of the product accordingly, reducing the defective rate of the product in subsequent production, and bringing good economic benefits to the enterprise.

[0024] Preferably, the first glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com