Gas phase fluidized bed process LLDPE catalyst, preparation and application thereof

A gas-phase fluidized bed and catalyst technology, which is applied in the field of gas-phase fluidized bed method LLDPE catalyst and its preparation and application, can solve the problems of unfavorable production equipment running smoothly, poor copolymerization ability, easy to generate static electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

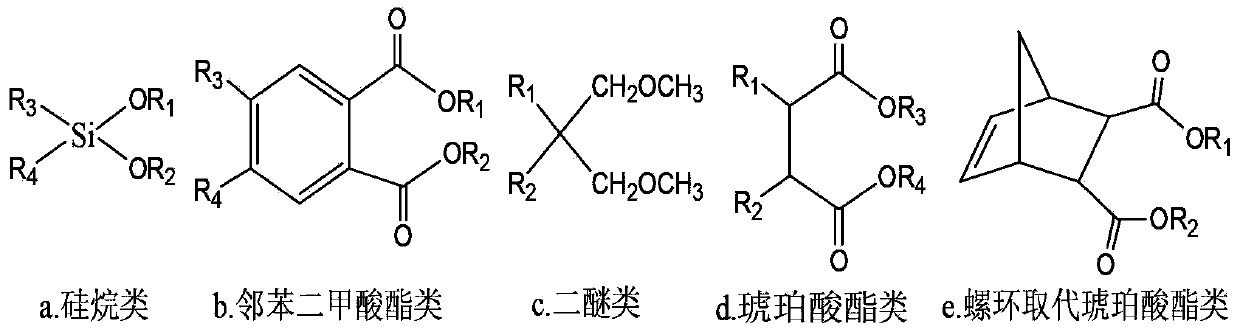

Method used

Image

Examples

Embodiment 1

[0027] Catalyst preparation:

[0028] (1) Under the protection of high-purity nitrogen, 1.6 L of n-decane, 80.0 g of anhydrous magnesium chloride and 331 mL of isooctyl alcohol were sequentially added to a 5 L reactor with a mechanical stirrer, and the temperature was raised to 130 ° C for 3 h to obtain a Homogeneous solution A.

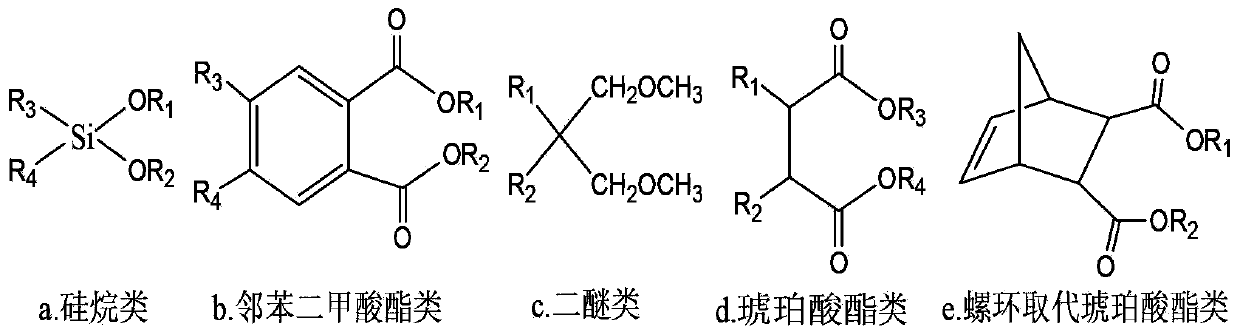

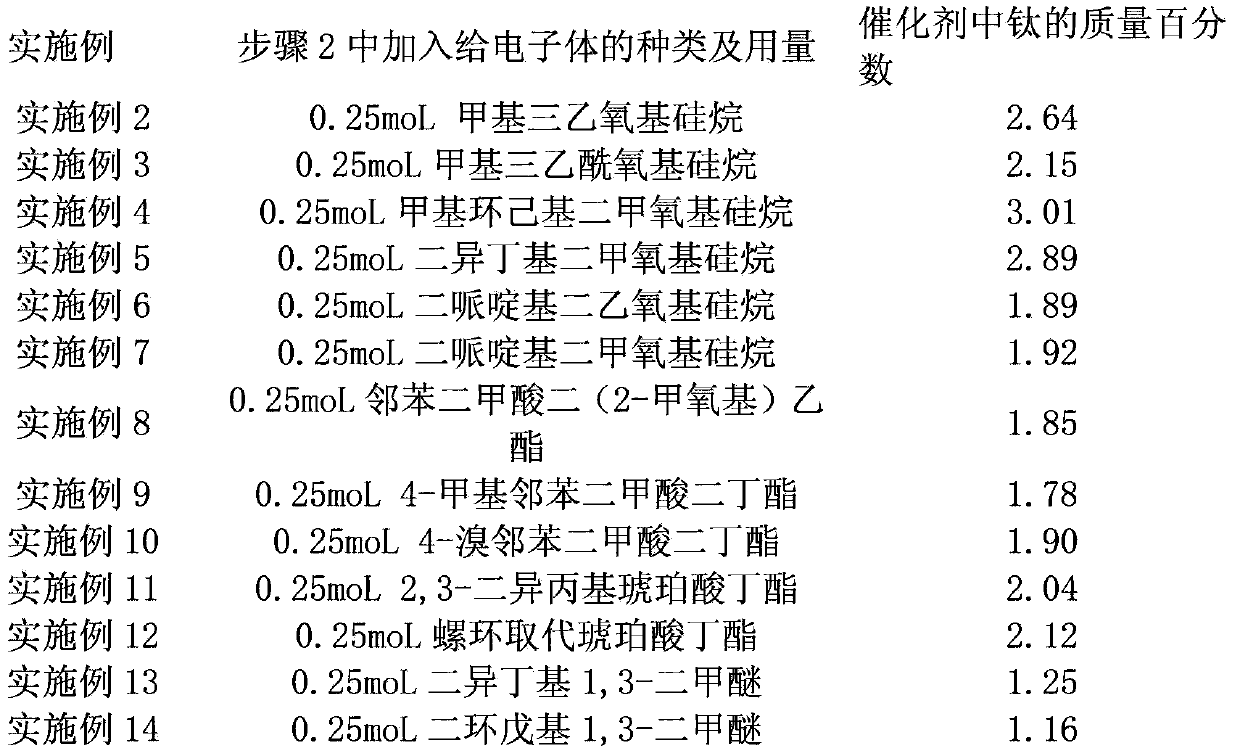

[0029] (2) Cool the above-mentioned reactant A solution to 90°C, add 89ml (0.25moL) tetrabutoxysilane, and react for 1 hour to obtain reactant B,

[0030] (3) At 90°C, add 400 g of heat-activated SiO 955 to reactant B 2 , reacted for 5h to obtain reactant C,

[0031] (4) Cool the reactant C obtained above to -7°C, and add 500 mL of TiCl dropwise within 2 hours 4into reactant C, and kept at this temperature for 0.5 hours, then slowly raised the temperature to 110°C for 2 hours, and removed the upper liquid by suction filtration to obtain reactant D,

[0032] (5) At 100°C, wash the reactant D2 times with toluene, then wash the reactant D7 times wit...

Embodiment 15

[0053] The preparation method of the catalyst is the same as that in Example 2. In the gas-phase polymerization evaluation method of ethylene, except that the molar ratio of hydrogen to ethylene is changed, the others are the same as in Example 1. The molar ratio of hydrogen to ethylene here is 0.28, and the gas-phase polymerization of ethylene results in See Table 3.

Embodiment 16

[0055] The preparation method of the catalyst is the same as that in Example 2. In the gas-phase polymerization evaluation method of ethylene, except that the molar ratio of hydrogen to ethylene is changed, the others are the same as in Example 1. The molar ratio of hydrogen to ethylene here is 0.38, and the gas-phase polymerization of ethylene results in See Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com