Steel framework light-duty building board

A technology of steel skeleton and building board, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of unfavorable building use, poor use effect, short service life, etc., and achieve production cost saving, low production cost and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

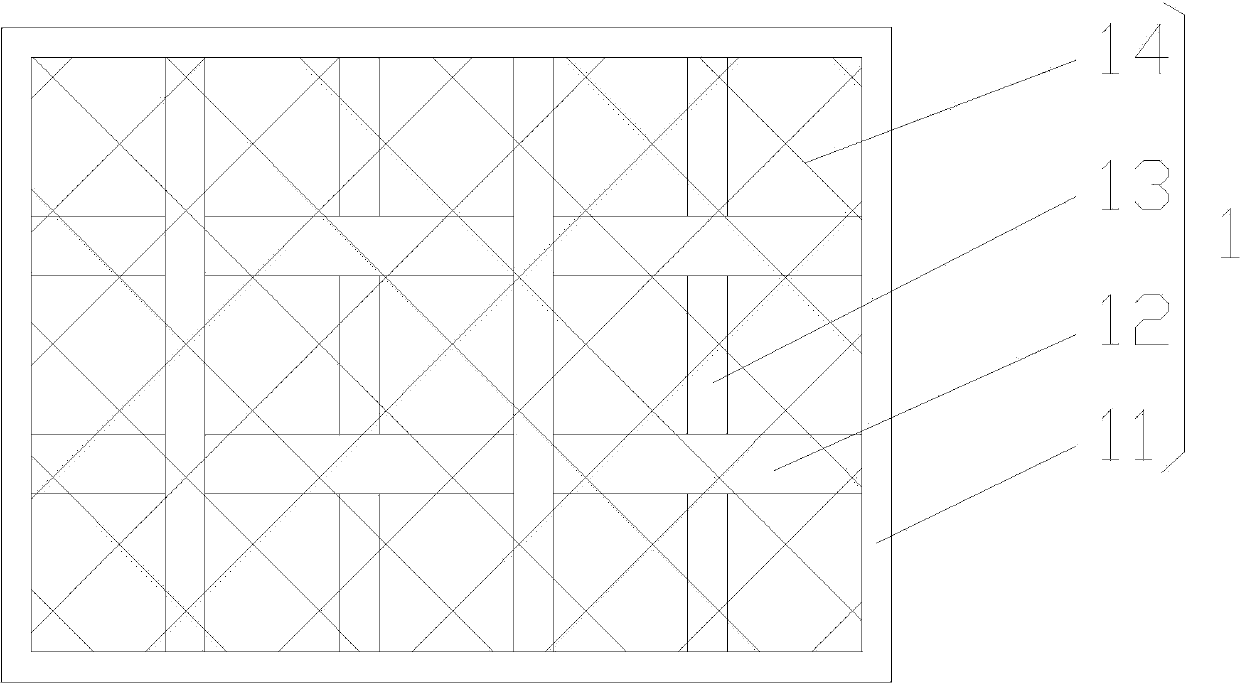

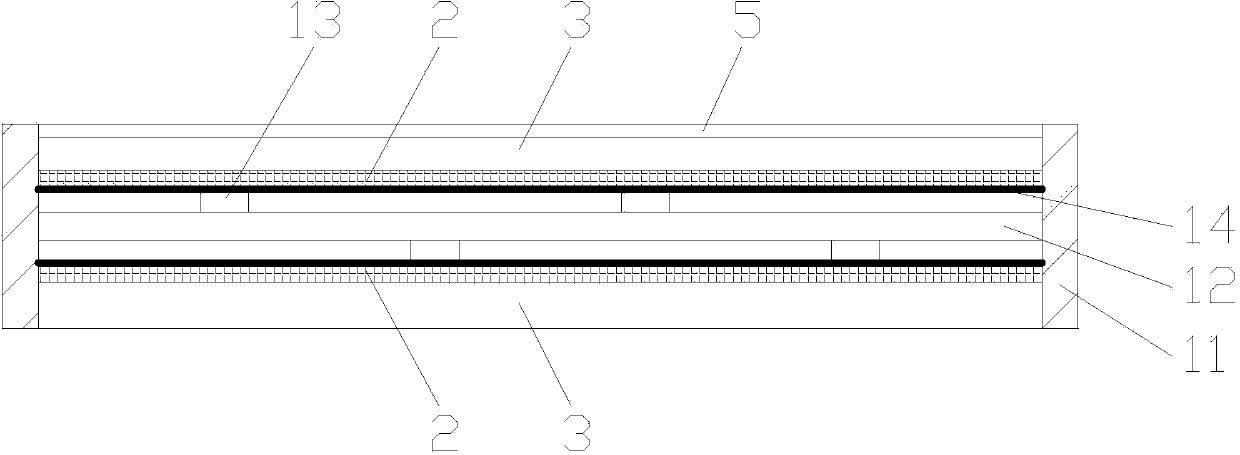

[0015] Such as Figure 1~2 as shown, figure 1 It is a structural schematic diagram of a steel skeleton in a steel skeleton light construction panel proposed by the present invention; figure 2 It is a schematic diagram of the side section structure of a steel frame light building panel proposed by the present invention.

[0016] refer to Figure 1~2 , a kind of steel frame light building board that the present invention proposes, comprises steel frame 1, insulation layer 2, and foamed cement layer 3, steel frame 1 surface is provided with anticorrosion coating, steel frame 1 includes hollow frame 11, two beams 12. Four vertical beams 13 and two reinforcing nets 14. The hollow frame 11 is surrounded by steel plates to form a rectangular frame. Two cross beams 12 are arranged in parallel at equal intervals along the vertical direction of the hollow frame 11. Both cross beams 12 are fixed. In the middle part of the inner side wall of the hollow frame 11, four vertical beams 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com