Smoothing reactor end-to-end capacitor discharge test system and transient wave trapper thereof

A technology of smoothing reactor and wave trap, which is applied in the field of smoothing reactor end-to-end capacitor discharge test system and its transient wave trap, which can solve the requirements of unreachable discharge time and short capacitor discharge duration, etc. problem, achieve the effect of improving voltage waveform, weakening voltage overshoot, and ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

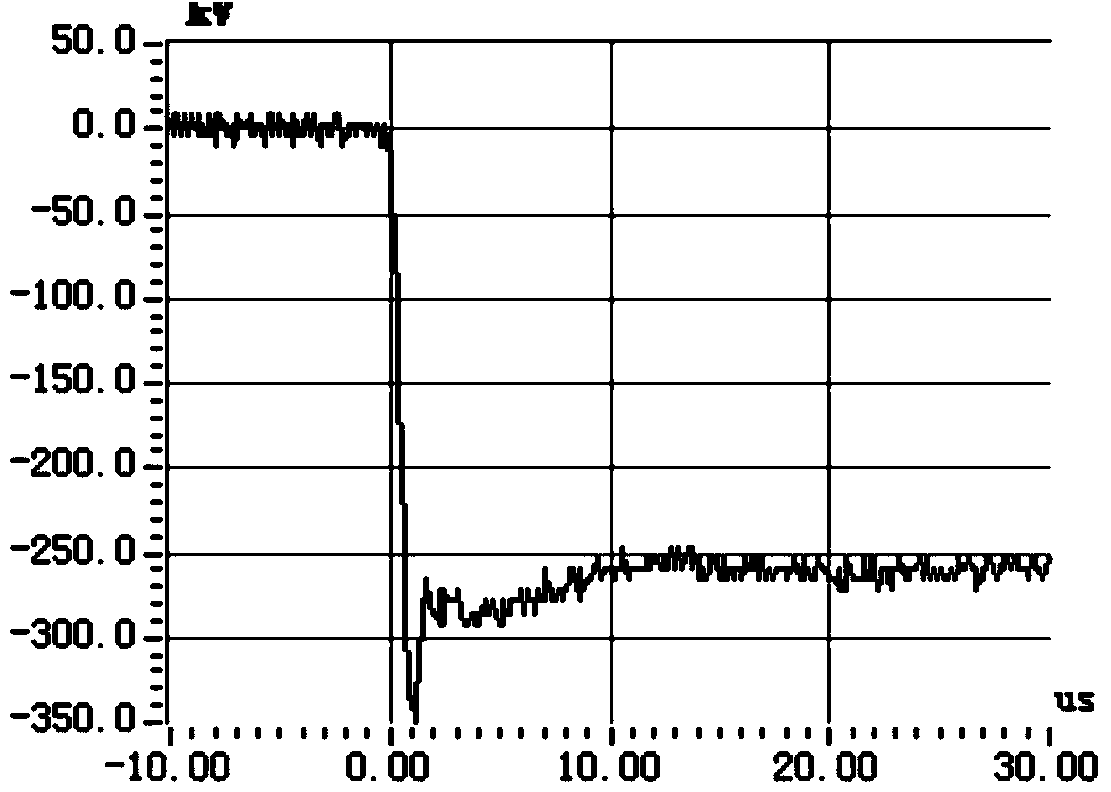

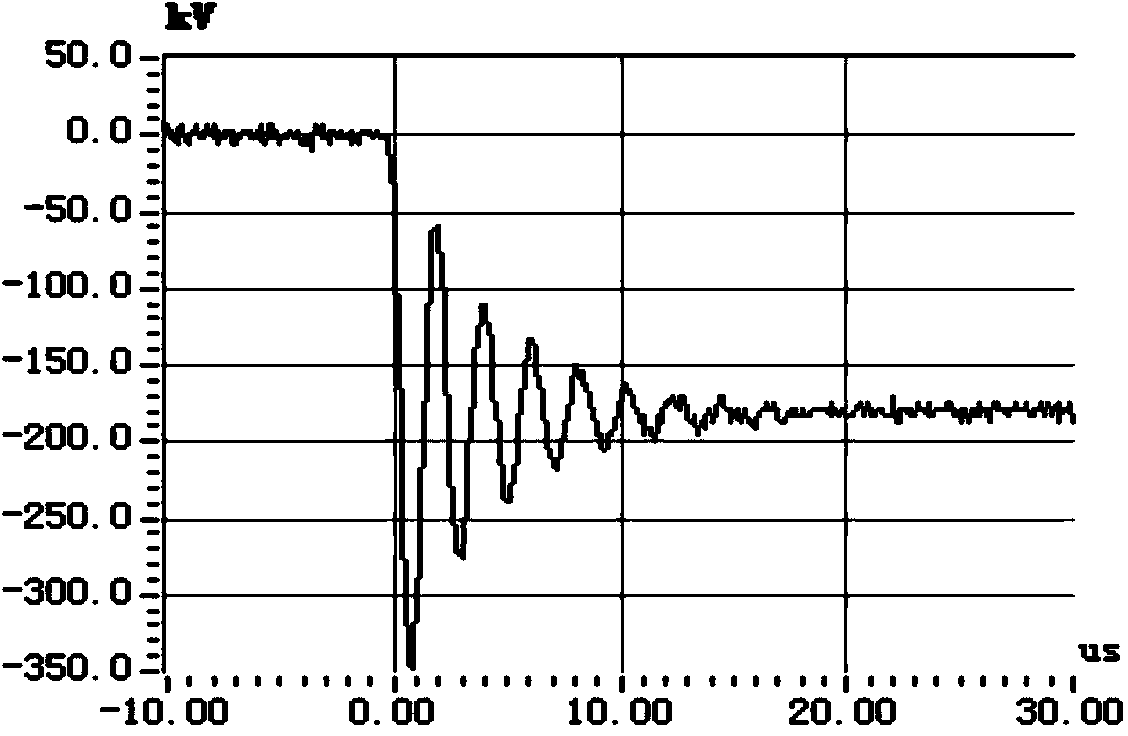

[0015] As we all know, in the end-to-end capacitor discharge test circuit of dry-type air-core smoothing reactor, stray capacitance, lead inductance, etc. will produce a strong high-frequency transient process on the rising edge of the wave front, forming a 1.8 times or even higher overshoot voltage. Usually, during the test process, the high-frequency overshoot is suppressed by increasing the damping resistance of the wave head, but the effect is not good. If the damping resistance value is increased blindly, the discharge duration will be seriously shortened, resulting in waveforms that do not meet the requirements of relevant standards for test duration.

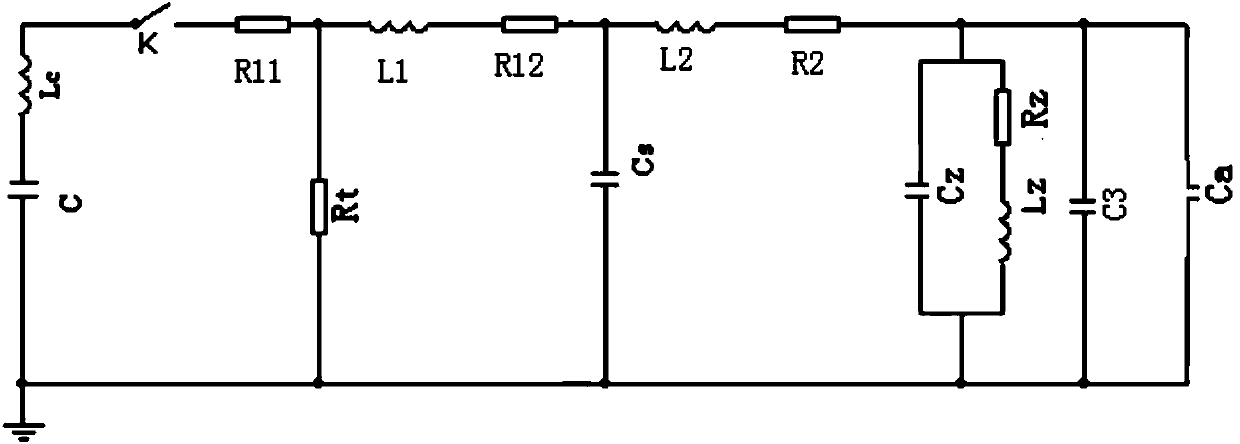

[0016] In view of this, the present invention provides a smoothing reactor end-to-end capacitor discharge test system. Such as figure 1 as shown, figure 1 The illustrated embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com