Selection optimization method of temperature measurement point combination for positioning errors of numerically-controlled machine tool under thermal effect

A positioning error, CNC machine tool technology, applied in program control, computer control, general control system, etc., can solve problems such as affecting calculation accuracy, large correlation of output signals, and increasing workload of measuring points, to simplify modeling Process, robustness and accuracy, the effect of saving temperature sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and implementation process.

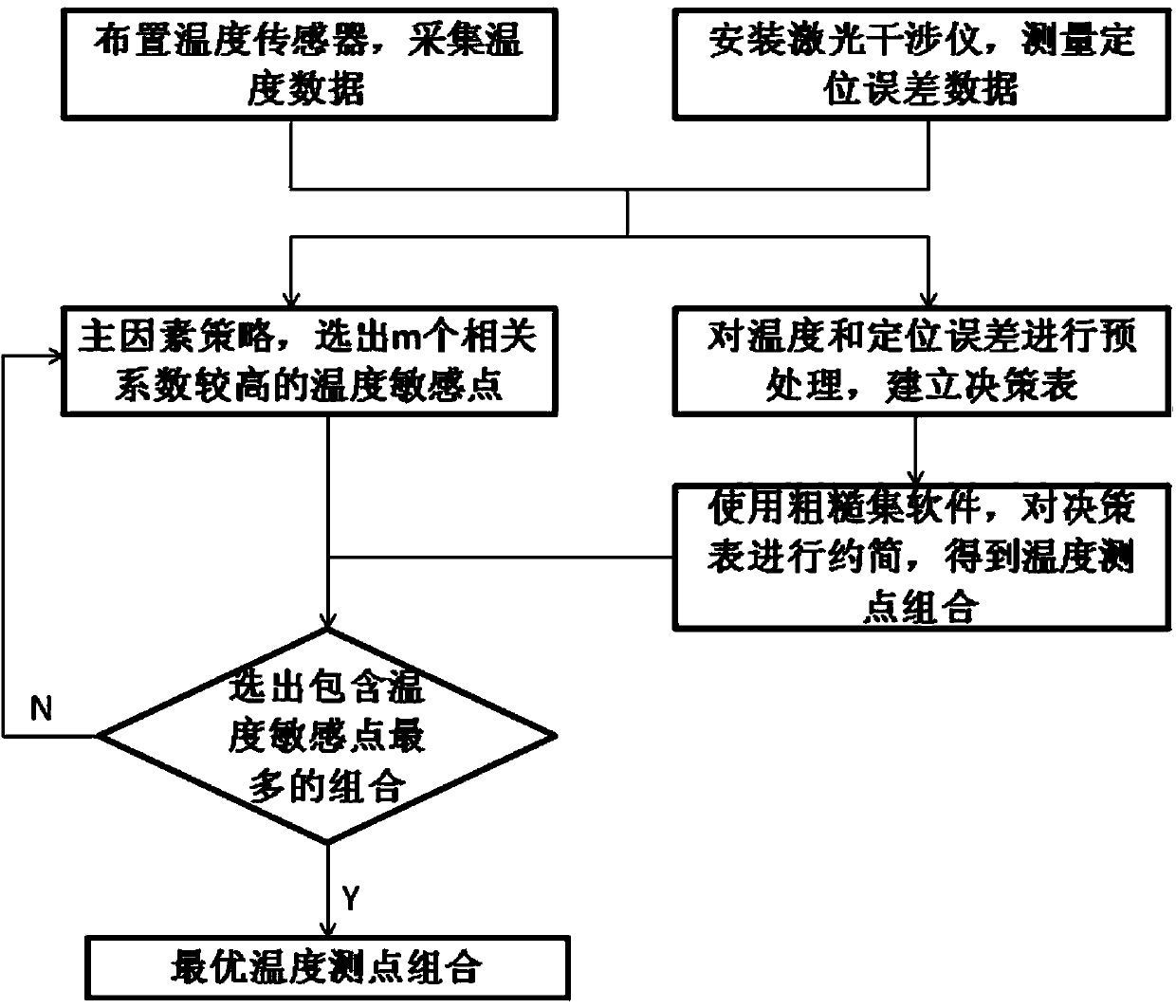

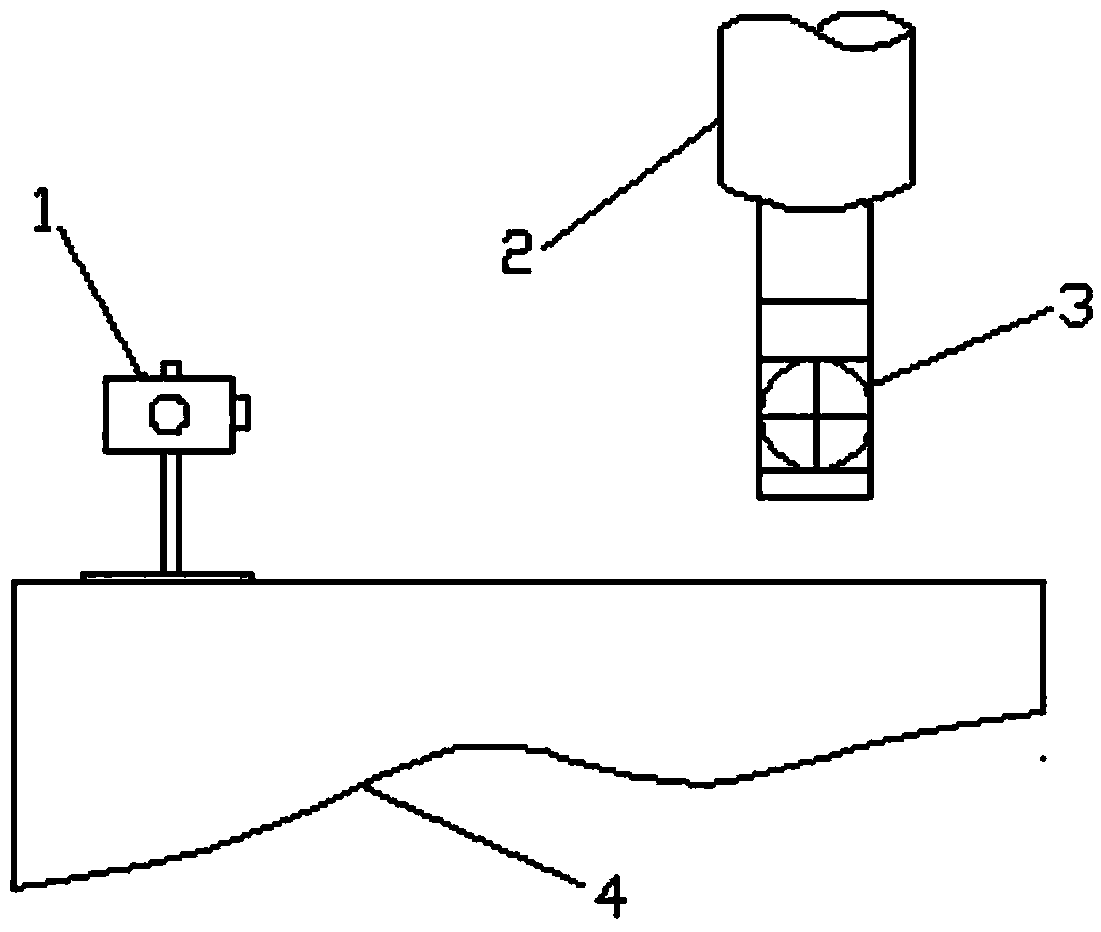

[0025] Such as Figure 1-3 As shown, the selection and optimization method of the machine tool positioning error compensation modeling temperature measuring point of the present invention is a comprehensive selection method based on gray relational analysis and rough set theory, and is realized according to the following steps:

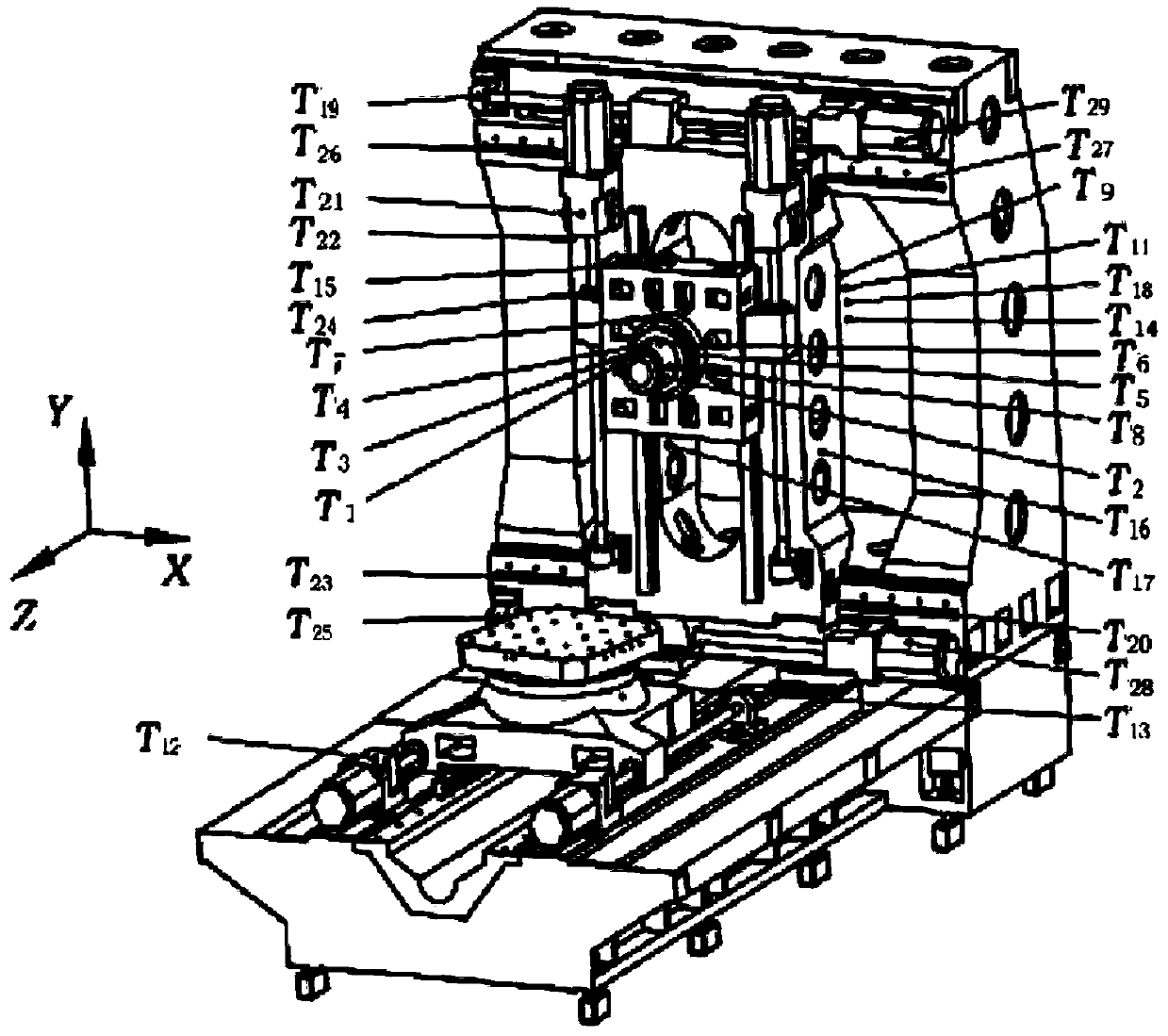

[0026] First, consider the factors related to the positioning error under the thermal effect, including the heat generated by the reciprocating motion of the moving parts of the machine tool, the heat generated by the motor, the heat transfer of various parts of the machine tool, and the influence of the ambient temperature. Based on this analysis, determine the location of the sensor in the experiment of collecting machine tool temperature data. . As shown in Table 1, the layout positions of the 29 sensors are detailed in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com