Rapid design and management method for spacecraft device installation fasteners

A technology of equipment installation and management methods, applied in the fields of instruments, calculations, data processing applications, etc., can solve the problems of high error rate, many types, large workload of fastener statistics and summary, and achieve automatic statistics and summary, Improve work efficiency and ensure the effect of uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

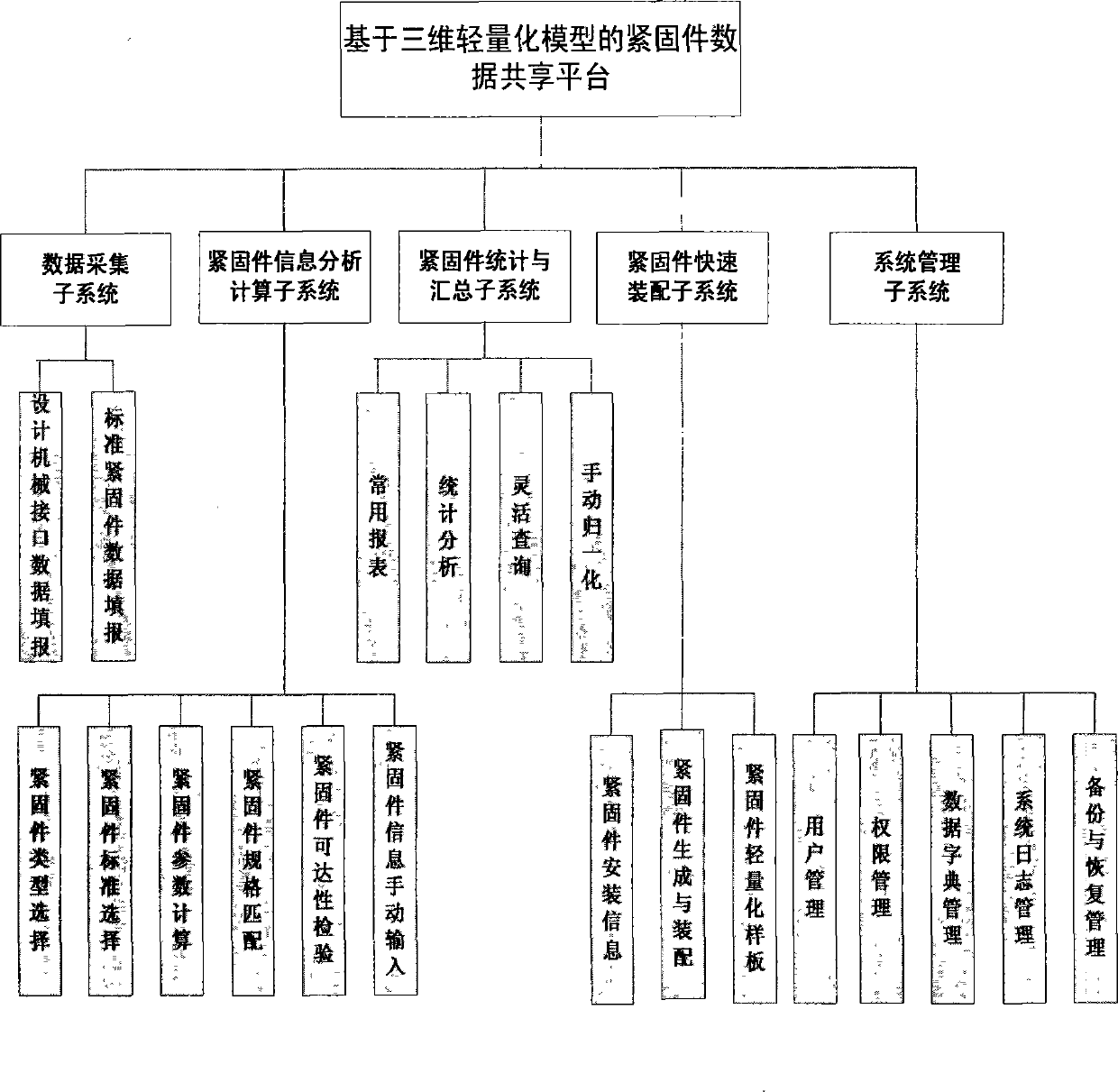

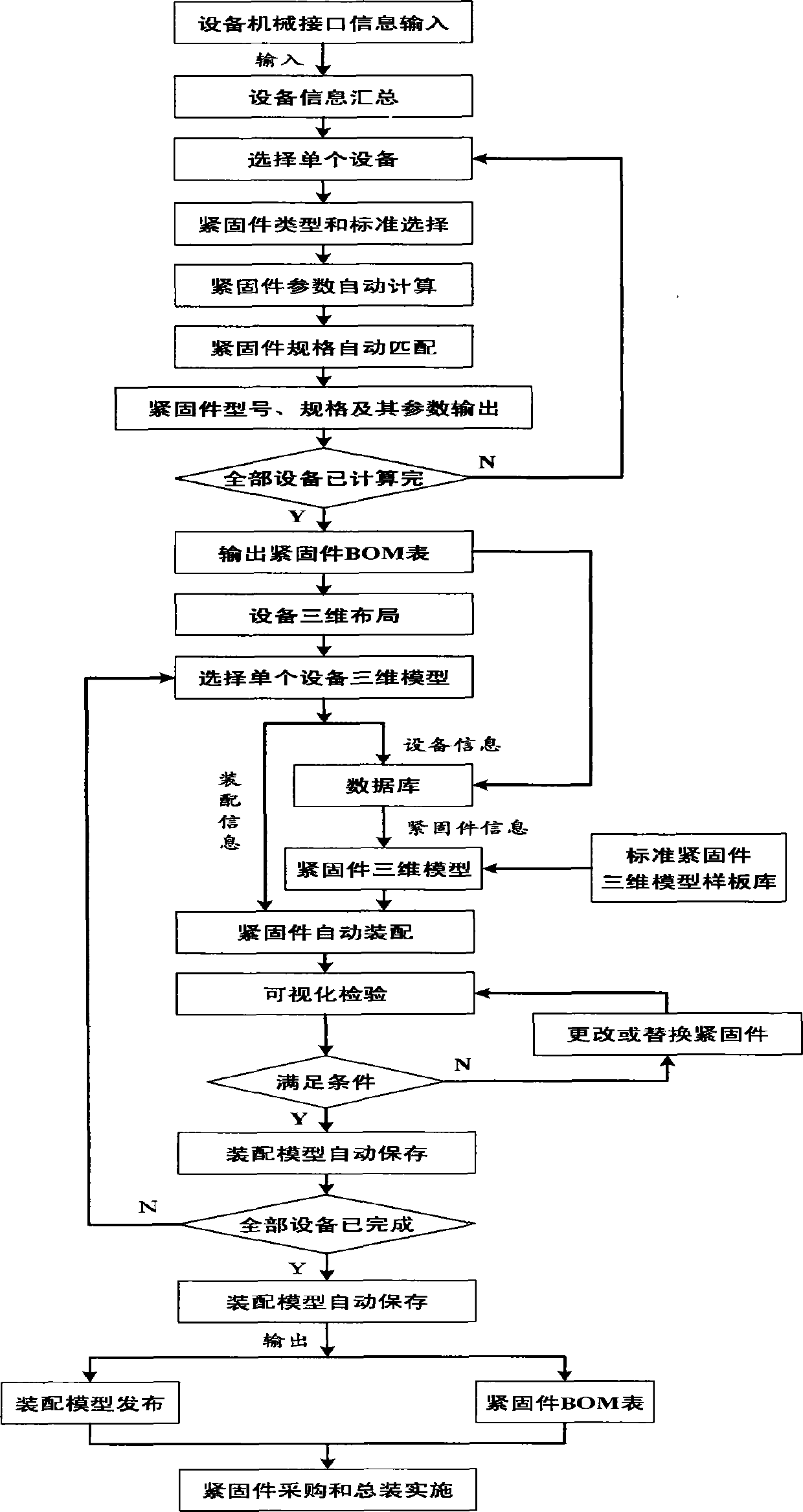

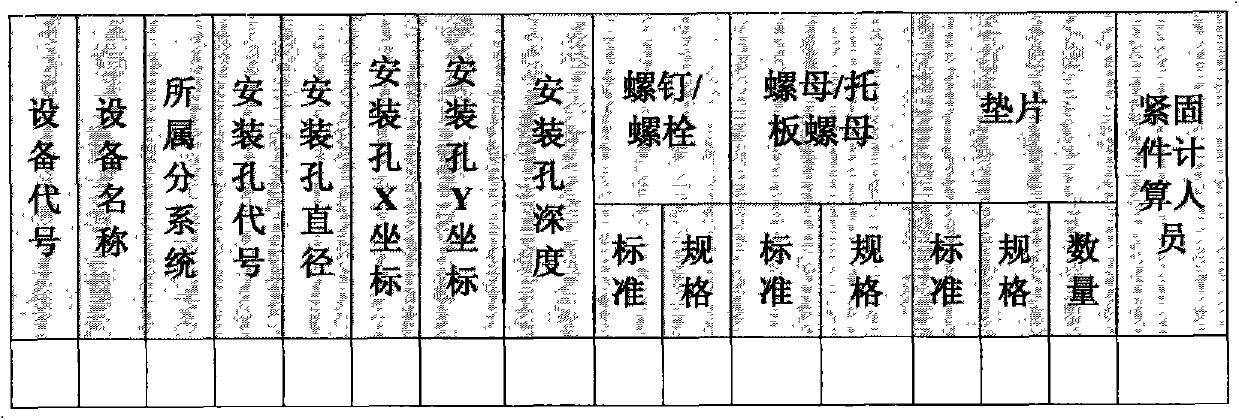

[0033] Starting from the three-dimensional layout of the spacecraft and the actual requirements of the final assembly, the present invention proposes a rapid design and management method for fasteners installed on spacecraft equipment, so as to realize the fasteners in the whole process of "design-matching-assembly-inspection" The information-based closed-loop management realizes the automatic calculation of equipment fastener parameters, automatic matching of specifications, parametric design and automatic assembly of 3D lightweight models, and visual inspection of fastener design results. It is applied to spacecraft 3D In the design process of layout and assembly, improve the efficiency of fastener design, solve the problem of unoptimized fastener design parameters, realize automatic statistics and summary of equipment fastener information, reduce the error rate cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com