Abutting machining process and equipment for improving excitation-characteristic matching ratio of combined-type mutual inductor

A combined transformer and excitation characteristic technology, applied in the field of transformers, can solve problems such as failure to leave the factory, high scrap rate, mismatching excitation characteristics, etc., and achieve the effect of improving yield rate, improving excitation characteristic matching rate, and improving positioning relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

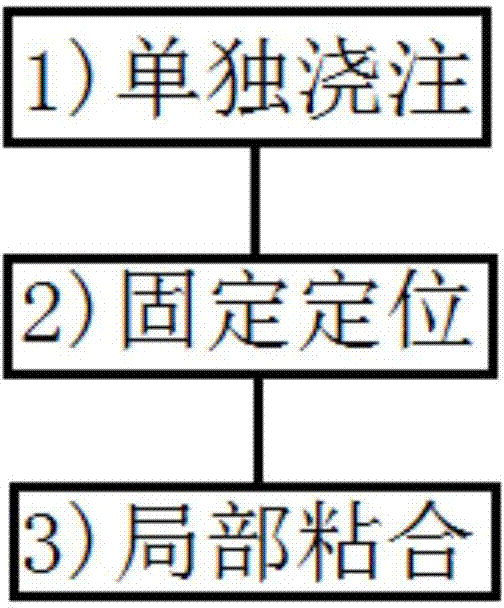

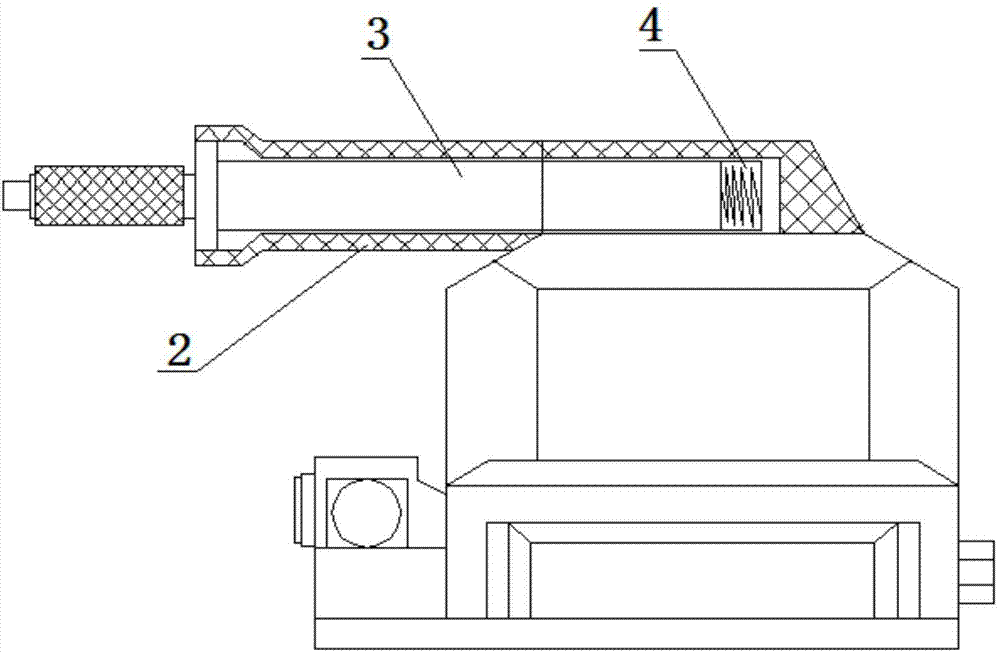

[0048] refer to figure 1 , figure 2 , image 3 , the butt joint processing technology to improve the matching rate of the excitation characteristics of the combined transformer includes the following three steps:

[0049] 1) Separate pouring: pour the single transformer alone, measure the electrical parameters of the completed transformer single, and group the transformer singles with at least two matching electrical parameters;

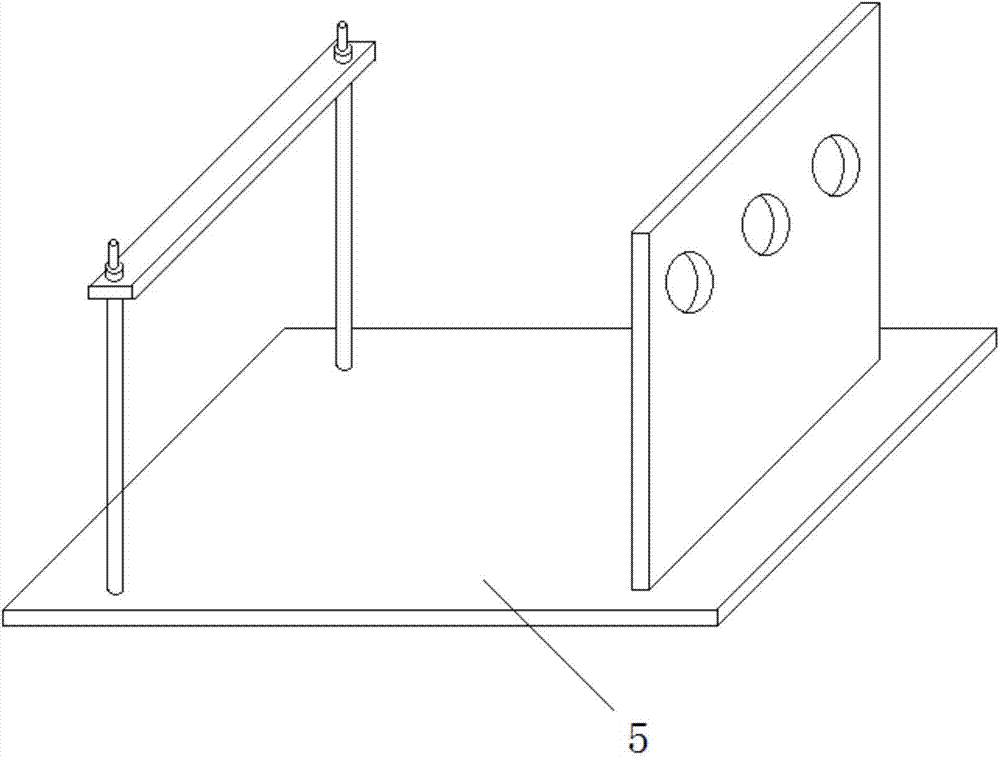

[0050] 2) Fixed positioning: fix at least two matched transformers with a fixed bracket 5;

[0051] 3) Partial bonding: at least two single transformers are bonded on the fixing bracket 5 with an adhesive to form a combined transformer.

[0052] The invention adopts the method of individual pouring first and then overa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com