Strip seeding production line for raising hybrid rice seedlings

A hybrid rice and assembly line technology, which is applied in sowing seeders, watering devices, gardening, etc., can solve the problems that the water spray mechanism cannot meet the seepage requirements of the seedling tray, is easy to be blocked in the diversion groove, and the seedling strengthening agent is difficult to be uniform. , to achieve reasonable design, avoid rotten seedlings and dead seedlings, and reduce the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

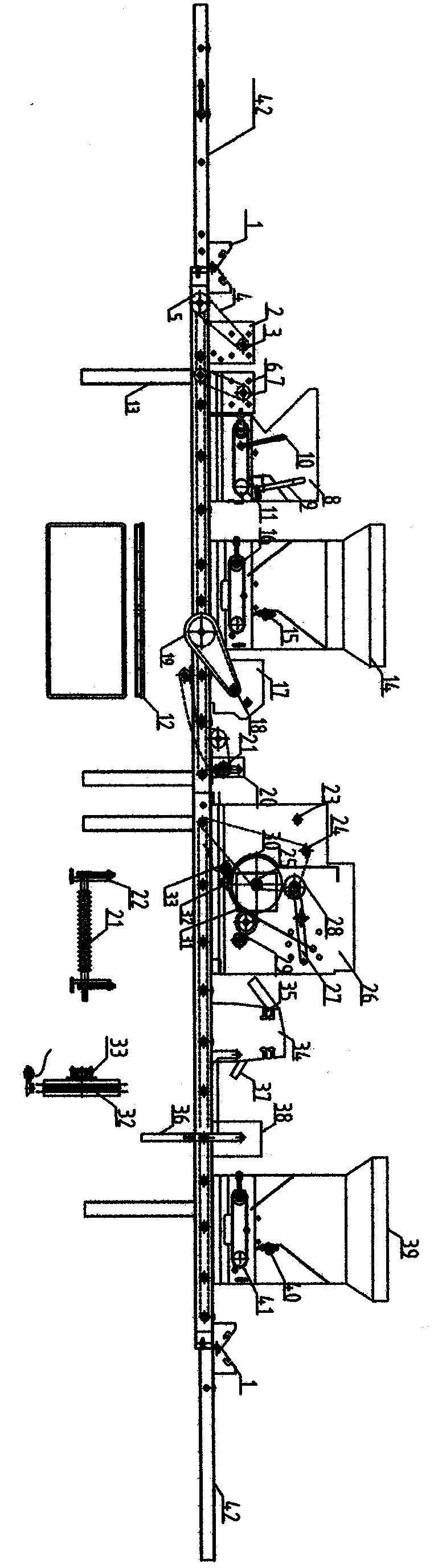

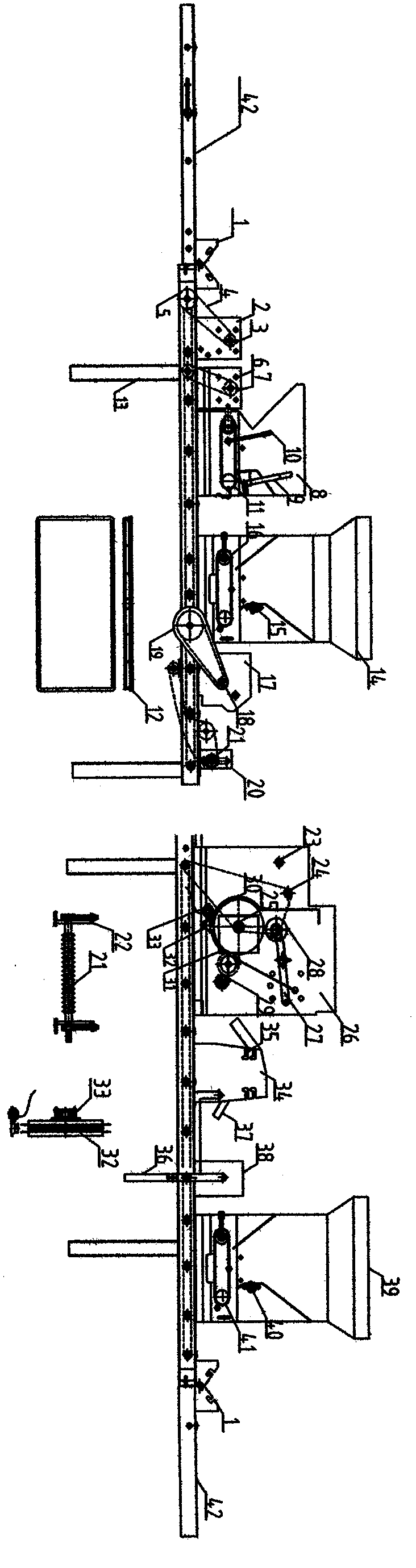

[0021] Such as Figure 1-2Shown, this hybrid rice seedling raising strip seeding assembly line is made up of front and back two parts frame (42), transmission device and each mechanism in order to facilitate transportation and storage. On the front part frame (42), be provided with closing device (1). The transmission device includes a driving motor (3), a transmission sprocket, a chain and a road wheel. The seedling tray (12) is moved forward through the transmission sprocket wheel and the chain driven traveling wheel, and passes through the bottom of the fertilization, subsoil, brush leveling, and groove-pressing mechanisms successively. The fertilization mechanism includes a driving motor (7), a fertilization box (8), a transmission closing and separating device (10), a transmission belt (11) and a volume adjusting device (9). F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com