Alginate adhesive bandage and manufacturing method of alginate adhesive bandage

A technology of alginate and bandages, applied in dressings, viscous dressings, etc., can solve the problems of insufficient viscosity, glue falling off, secondary damage, etc., and achieve the effect of strong viscosity, preventing degumming, and promoting healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

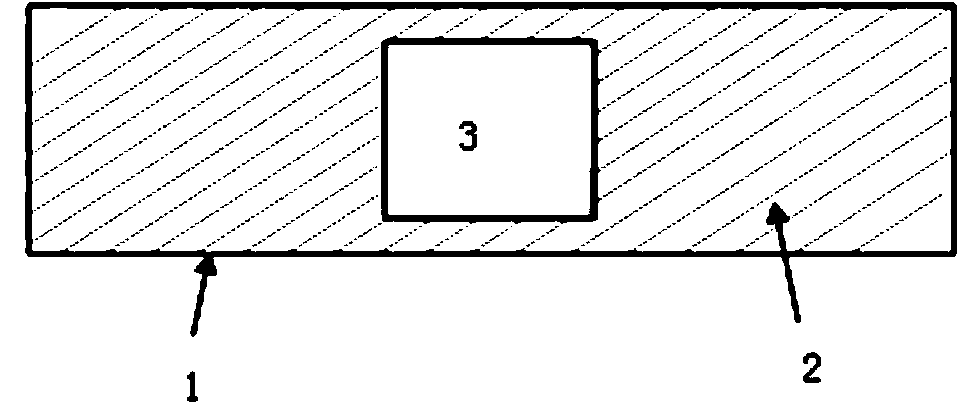

[0023] See figure 2 , the alginate bandage of the present embodiment is made of waterproof fabric 1, medical acrylic glue layer 2, 100% alginate non-woven fabric 3 and protective paper; the latitudinal elasticity of waterproof fabric 1 is greater than 150%; medical acrylic glue Layer 2 is coated on one side of waterproof fabric 1; 100% alginate non-woven fabric 3 is placed on medical acrylic glue layer 2; release paper is covered on medical acrylic glue layer 2 and 100% alginate non-woven fabric 3 superior. The thickness of the waterproof fabric 1 is not more than 300 g / m2, and it has been treated with three levels of waterproofing. The medical acrylic glue layer 2 is a full coating or a dissatisfied coating with vacancies.

[0024] The production method is characterized in that it comprises the following steps:

[0025] Step 1: Prepare elastic fabric with a weft elasticity greater than 150%, and go through three-level waterproof treatment; the weft elastic fabric can be m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com