Programmed temperature rise sterilization method of edible fungi culture material

A sterilization method and culture material technology, applied in heating and other directions, can solve the problems of folic acid loss and affecting mycelial growth, etc., and achieve the effects of convenient operation, reduced nutrient loss, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A kind of sterilization method of edible fungus compost

[0016] Adopt the three-stage stepwise program sterilization method, that is, keep the temperature at 92°C for 60 minutes, raise the temperature to 103°C and keep it for 60 minutes, then raise the temperature to 122°C and keep it for 90 minutes, and simmer for 90 minutes. When the pressure of the autoclave drops to zero, the temperature drops to 90 ℃, open the sterilizer, start the air filter, and push out the sterilizer for cooling.

Embodiment 2

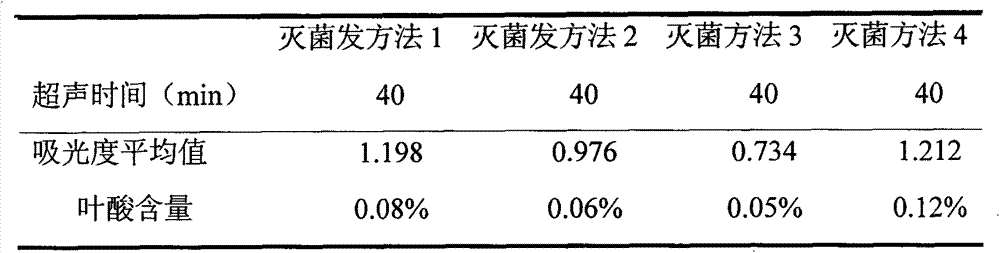

[0017] The determination and analysis of the content of folic acid in the compost of different sterilization methods of embodiment 2

[0018] Sterilization method 1: Sterilize at 121°C for 2 hours;

[0019] Sterilization method 2: 60 minutes at 100°C, intermittent vacuum pumping, the pressure in the kettle is pumped to -0.05~-0.06MPa, and it takes 15 minutes to raise the temperature in the kettle to 121°C, keep the pressure at 0.11MPa for 90 minutes, and turn off the steam , the sterilization is over;

[0020] Sterilization method 3: Sterilize at 100°C for 15 hours;

[0021] Sterilization method 4: the sterilization method described in Example 1;

[0022] Take 4.2g of the culture material obtained by the above-mentioned different sterilization methods and add 15mL of 0.1mol / mL NaOH buffer solution to 12 centrifuge tubes (3 centrifuge tubes for each), and put them into a digitally controlled ultrasonic cleaner for 40 minutes of ultrasonication. Take out the filter and measur...

Embodiment 3

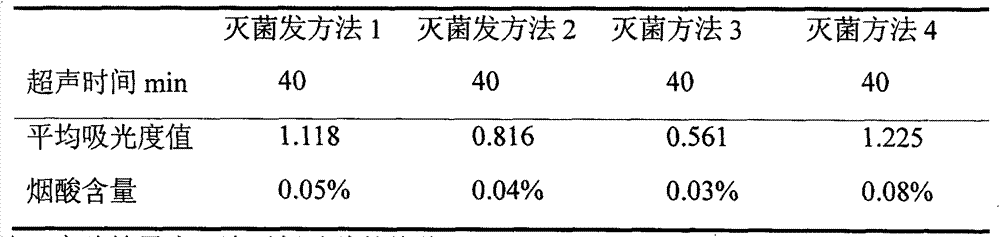

[0028] The determination and analysis of the content of nicotinic acid in the compost of different sterilization methods in embodiment 3

[0029] Take 4.2 g of the culture material obtained by different sterilization methods described in Example 1, add 15 mL of distilled water to 12 centrifuge tubes (3 centrifuge tubes for each), and put them into a digitally controlled ultrasonic cleaner for 60 minutes of ultrasonication. Take out the filter and measure the absorbance at different wavelengths with a UV spectrophotometer. The data were brought into the corresponding standard curve, and the content of niacin in the compost was calculated. The results are shown in Table 2.

[0030] Preparation of niacin standard curve: Accurately weigh an appropriate amount of niacin standard product (calculated as anhydrous matter), dissolve it in distilled water, and prepare a niacin stock solution with a concentration of 100 μl / mL. Prepare 5, 10, 15, 25, 30, 40, 60 μl / mL solutions, use disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com