A method for coating a UV-resistant bright and transparent composite coating

A composite coating and UV-resistant technology, which is applied to coatings, devices for coating liquid on the surface, and pre-treated surfaces, etc., can solve the problems of easy decomposition of chain segments and poor UV resistance, and achieve UV weather resistance, Mold resistance and weather resistance, the effect of excellent weather resistance

Active Publication Date: 2016-08-17

NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The resins used in carbon fiber composites and glass fiber composites generally use epoxy resins. According to literature reports, resin systems containing epoxy structures have poor UV resistance, and the chain segments are easily decomposed under ultraviolet light.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

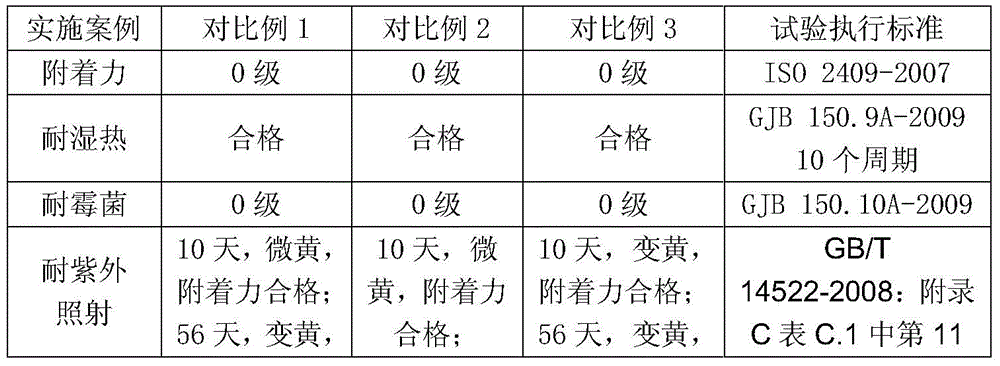

Comparison scheme

Effect test

Embodiment 1

[0044] Varnish A is an acrylic varnish, and Varnish B is a trifluorofluorocarbon varnish.

Embodiment 2

[0046] Varnish A is an acrylic varnish, and Varnish B is a tetrafluorocarbon varnish.

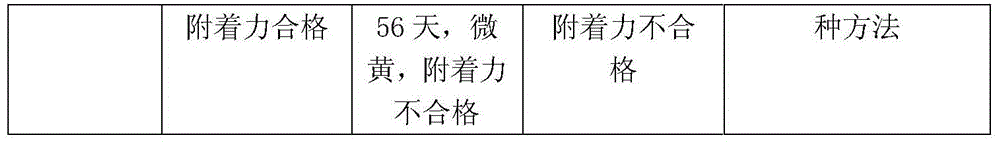

[0047] The environmental adaptability of the composite coating paint film of table 2 embodiment gained

[0048]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a method for coating an ultraviolet-resistant bright and transparent composite coating. The primer varnish used in the invention is acrylic varnish, and the finishing varnish is one of trifluorofluorocarbon varnish or tetrafluorocarbon varnish. The composite coating is used on metal, carbon fiber composite materials or glass fiber composite materials to form a bright and transparent coating that can show the color of the metal body and the fabric texture of the composite material, and the composite coating film has high hardness, beautiful appearance, and Excellent weather resistance against heat and humidity, mold and UV rays.

Description

technical field [0001] The invention relates to a method for coating a composite coating, in particular to a method for coating a bright and transparent composite coating with ultraviolet resistance on metals, carbon fiber composite materials or glass fiber composite materials. Background technique [0002] Transparent coating can show the surface texture and body color of the substrate. As people have higher and higher requirements for product appearance, many products need to be sprayed with transparent coating to improve the appearance of the product, and metal and carbon fiber / glass fiber composite materials are no exception. The resins used in carbon fiber composites and glass fiber composites generally use epoxy resins. According to literature reports, resin systems containing epoxy structures have poor UV resistance, and the chain segments are easily decomposed under ultraviolet light. If the appearance of this kind of composite product is to adopt a transparent coati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05D5/00B05D3/02B05D3/04B05D3/00

Inventor 霍明亮黄晓群王海东申月英曹永杰

Owner NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com