Automatic bowl blank transfer device

A technology of automatic transfer and bowl billet, which is applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems of low degree of automation and work efficiency, high manual labor intensity, cumbersome reversing action of bowl billet, etc. , to achieve the effect of simple structure, high space utilization rate and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

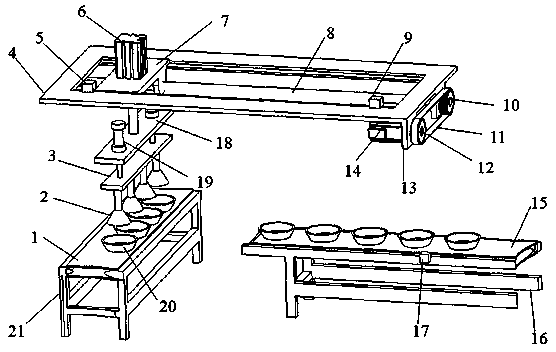

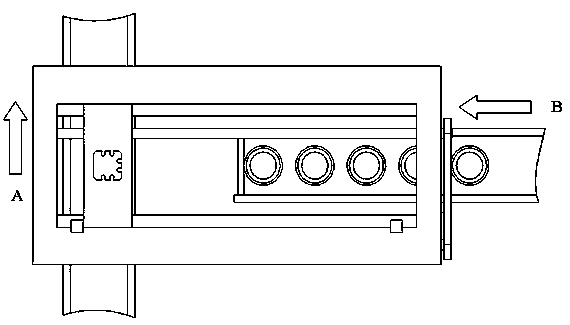

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] control figure 1 and figure 2 , before the device works, the mobile motor 14 on the mobile motor mounting plate 13 drives the large pulley 10 to rotate through the small pulley 12 and the belt 11, and the large pulley 10 drives the screw mandrel 8 to rotate, and the screw mandrel 8 of the rotation makes the horizontal movement The plate 7 moves to the right, and stops when it touches the right travel switch 9. At the same time, the index motor 6 drives the suction cup cylinder mounting plate 18, the suction cup cylinder 19 and the suction cup 2 to rotate 90 degrees, and the bowl blank 20 to be transferred Be transported to directly below the sucker 2 by the conveyor belt 2 15, and the conveyor belt 2 15 stops moving when reaching the quantity specified by the counter 17, and the device completes the preparatory work so far.

[0016] Then the sucker cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com