A kind of preparation method and its product of enzymolysis highly active seaweed organic fertilizer

An organic fertilizer and high-activity technology, which is applied in the direction of organic fertilizers, can solve the problems of poor chemical hydrolysis and damage the activity of endogenous substances in seaweed, and achieve improved activity, which is beneficial to plant growth and development, balanced growth, and large-scale increase in production. and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

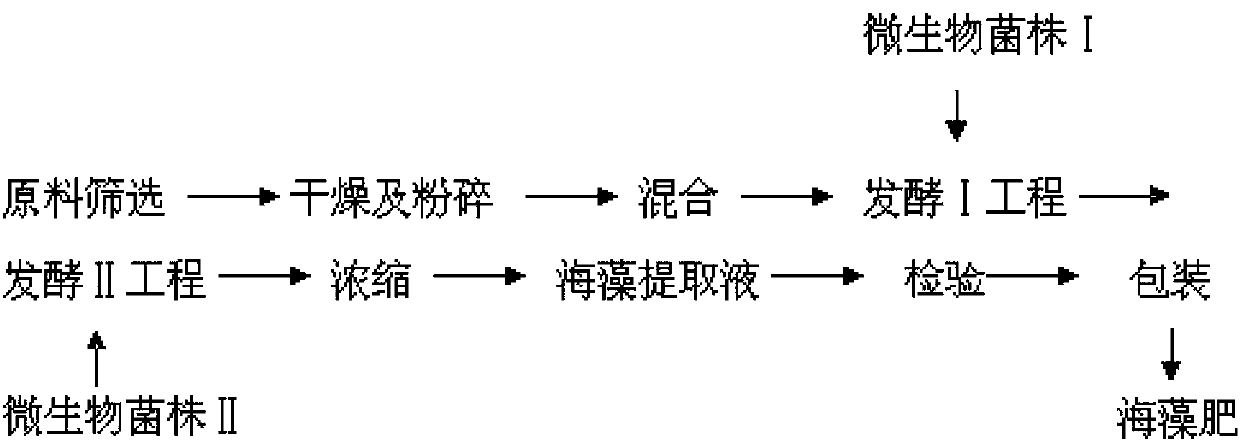

[0055] Such as figure 1 Shown, a kind of preparation method of enzymolysis highly active seaweed organic fertilizer comprises:

[0056] (1) Raw material screening

[0057] Sea millet picked in season from September to December is selected, dried and crushed into a powder with a fineness of about 0.1mm; Semen psyllium is also dried and pulverized, and the two substances are combined into sea millet: Semen psyllium = 99:1 The mass ratio is mixed evenly.

[0058] (2) Enzymatic fermentation

[0059] The first stage of fermentation: Weigh 400kg of the mixed sea millet and psyllium raw materials according to the fermentation process regulations, put them in the fermentation tank, add 1600kg of water, stir them evenly, and steam sterilize at 121°C for 30 minutes . After sterilization, when the temperature of the material drops to 38°C, keep the temperature constant, insert the cultured actinomycete liquid seeds according to the aseptic method, the inoculum amount is 40kg, and fer...

Embodiment 2

[0063] Such as figure 1 Shown, a kind of preparation method of enzymolysis highly active seaweed organic fertilizer comprises:

[0064] (1) Raw material screening

[0065] Sea millet picked in season from September to December is selected, dried and crushed into a powder with a fineness of about 0.1mm; Semen psyllium is also dried and pulverized, and the two substances are combined into sea millet: Semen psyllium = 99:1 The mass ratio is mixed evenly.

[0066] (2) Enzymatic fermentation

[0067] The first stage of fermentation: Weigh 400kg of the mixed sea millet and psyllium raw materials according to the fermentation process regulations, put them in the fermentation tank, add 1600kg of water, stir them evenly, and steam sterilize at 121°C for 30 minutes . After sterilization, when the temperature of the material drops to 42°C, keep the temperature constant, insert the cultured actinomycete liquid seeds according to the aseptic method, the inoculum amount is 20kg, and fer...

Embodiment 3

[0071] Such as figure 1 Shown, a kind of preparation method of enzymolysis highly active seaweed organic fertilizer comprises:

[0072] (1) Raw material screening

[0073] Select sea millet picked in the season from September to December, dry it and crush it into a powder with a fineness of about 0.1mm; Semen psyllium is also dried and pulverized, and combine the two substances into sea millet: Semen psyllium = 98:2 The mass ratio is mixed evenly.

[0074] (2) Enzymatic fermentation

[0075] The first stage of fermentation: Weigh 400kg of the mixed sea millet and psyllium raw materials according to the fermentation process regulations, put them in the fermentation tank, add 1600kg of water, stir them evenly, and steam sterilize at 121°C for 30 minutes . After sterilization, when the temperature of the material drops to 35°C, keep the temperature constant, insert the cultured actinomycete liquid seeds according to the aseptic method, the inoculum amount is 100kg, and fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com