A high-gloss flame-retardant scratch-resistant polypropylene composition and its preparation method

A polypropylene composition and scratch-resistant technology, applied in the field of polyolefins, can solve the problems of reducing the gloss of PP, the impact resistance of the material, and the gloss of the material to a large extent, and achieve the effect of reducing the influence of the surface gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

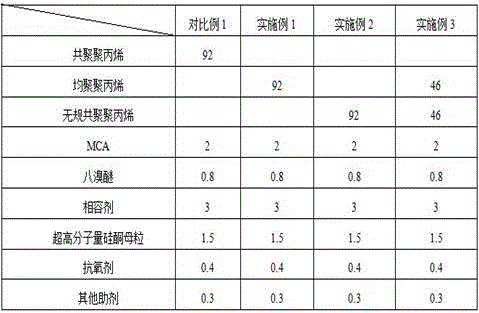

[0041] Table 1: Weight ratio

[0042]

[0043] (1) Weigh raw materials according to the weight ratio in Table 1: polypropylene, MCA, octabromoether, compatibilizer, anti-scratch agent, antioxidant, other additives;

[0044] (2) Put polypropylene, MCA, octabromoether, compatibilizer, anti-scratch agent, antioxidant and other additives together in a high mixer and mix for 10 minutes;

[0045] (3) Put the material into the twin-screw extruder, control the feeding speed, extrude and granulate, the speed of the twin-screw machine is 300 rpm; the vacuum degree is ≥0.06MPa, and the twin-screw extrusion process is listed in Table 2 middle.

[0046] Table 2: Twin-screw extrusion process

[0047]

[0048] It should be noted:

Embodiment 1

[0050] The compatibilizer used in embodiment 1, comparative example 1 is polypropylene graft maleic anhydride; The compatibilizer used in embodiment 2, embodiment 3 is polyethylene graft maleic anhydride.

[0051] The high-gloss flame-retardant and scratch-resistant polypropylene developed according to the above-mentioned process and formula, the glossiness prepared from homopolymerized and random copolymerized polypropylene is obviously better than that of ordinary copolymerized polypropylene. To prepare high-gloss flame-retardant and scratch-resistant polypropylene, random copolymerized polypropylene and homopolymerized polypropylene can be used as base materials.

Embodiment 4~6

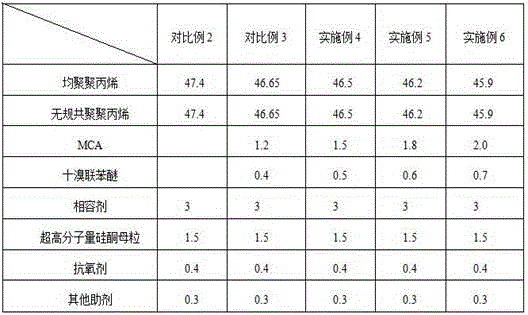

[0053] Table 4: Weight ratio

[0054]

[0055] (1) Weigh raw materials according to the weight ratio in Table 4: polypropylene, MCA, decabromodiphenyl ether, compatibilizer, scratch-resistant agent, antioxidant, other additives;

[0056] (2) Put polypropylene, MCA, decabromodiphenyl ether, compatibilizer, anti-scratch agent, antioxidant and other additives together in a high mixer and mix for 10 minutes;

[0057] (3) Put the material into the twin-screw extruder, control the feeding speed, extrude and granulate, the speed of the twin-screw machine is 300 rpm; the vacuum degree is ≥0.06MPa, and the twin-screw extrusion process is listed in Table 2 middle.

[0058] Table 5: Performance comparison

[0059]

[0060] It should be noted:

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com