Steel for high-speed train axle containing niobium and titanium

A high-speed train and axle steel technology is applied to alloy structural steel for high-speed train axles and its heat treatment process, and in the field of axle steel, which can solve the problem of high cost and achieve the effects of improving hardenability, improving overall performance and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are used to illustrate the present invention, but the protection scope of the present invention is not limited to the following examples.

[0029] The production process of the vanadium-containing titanium high-speed train axle steel of the present invention is as follows: electric arc furnace or converter smelting→LF furnace refining→RH or VD vacuum degassing→continuous casting→slab heating furnace heating→axle blank rolling→axle blank forging→ Rough turning of the rough axle → processing of the full end face of the axle → normalizing + quenching + high temperature tempering heat treatment → finishing turning of the outer circle of the axle → boring of the inner hole of the axle → cylindrical grinding → flaw detection.

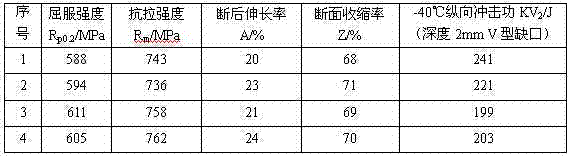

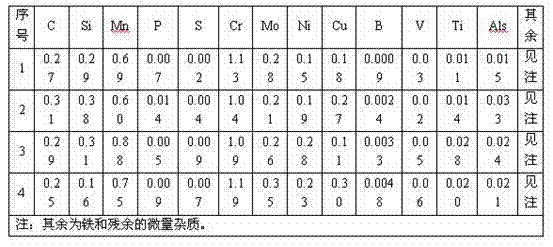

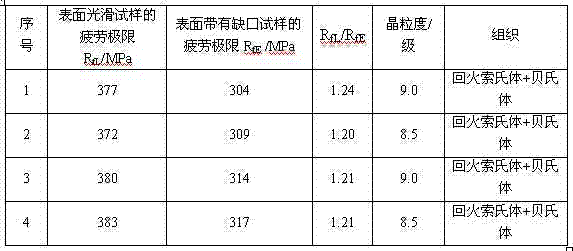

[0030] Embodiments of the smelting chemical composition, main heat treatment process parameters and performance of vanadium-containing titanium high-speed train axle steel of the present invention are as follows:

[0031] The hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com