Chemical vapor deposition equipment and method for silicon carbide

A chemical vapor deposition, silicon carbide technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of influence, unfavorable product performance, unable to meet high-precision process and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

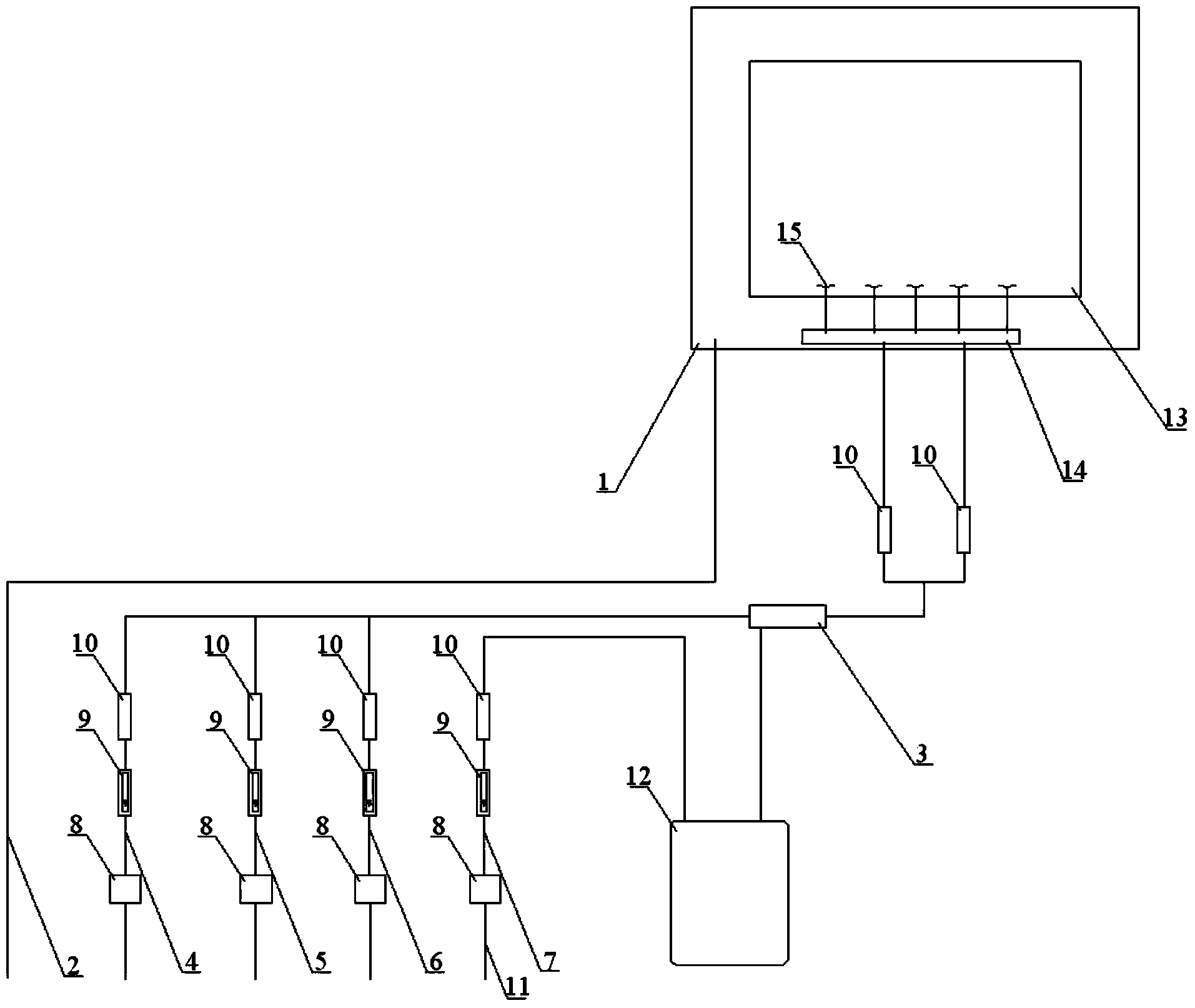

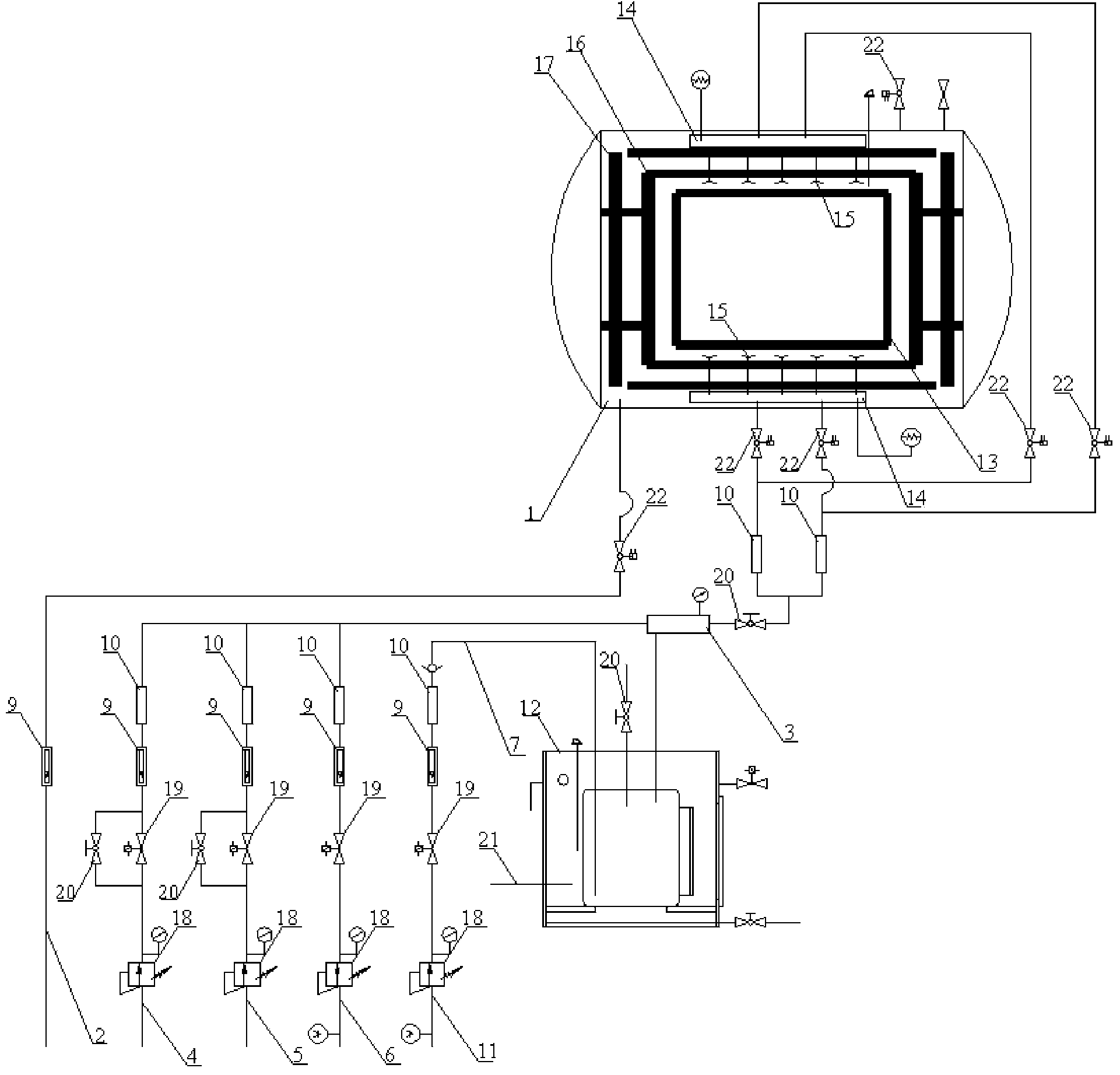

[0049] The schematic structural diagram of the silicon carbide chemical vapor deposition equipment provided in embodiment 1, as figure 1 shown. Among them, 1 is the chemical vapor deposition chamber, 2 is the inert gas inlet pipe, 3 is the mixing device, 4 is the first process gas inlet pipe, 5 is the second process gas inlet pipe, 6 is the third process gas inlet Pipe, 7 is the fourth process gas inlet pipe, 8 is the control valve, 9 is the volume flow meter, 10 is the mass flow controller, 11 is the carrier gas inlet pipe, 12 is the deposition source storage device, 13 is the chemical vapor deposition chamber Body, 14 is a gas distribution box, 15 is a gas nozzle, 16 is a heating element, 17 is a heat insulation layer, 18 is a pressure reducing valve, 19 is a solenoid valve, 20 is a manual ball valve, 21 is a heating pipe, and 22 is a pneumatic ball valve.

[0050] The chemical vapor deposition chamber (1) comprises: a chemical vapor deposition chamber (13); a gas distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com