Method and device for forming optical film on workpiece

A technology of optical film and workpiece, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as unevenness, film layer shedding and deposition amount, etc., achieve uniform energy distribution, easy process, and wide application The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

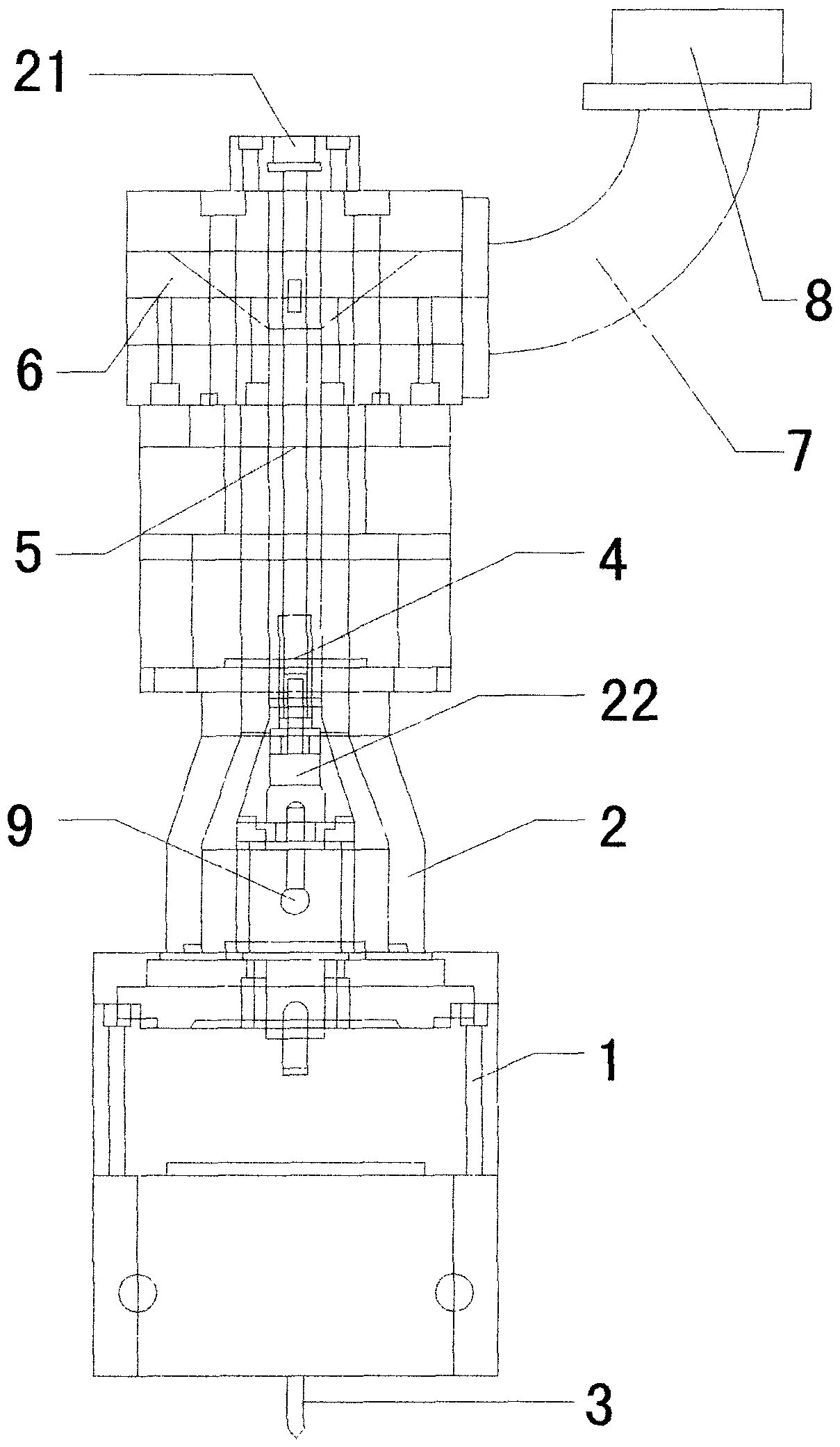

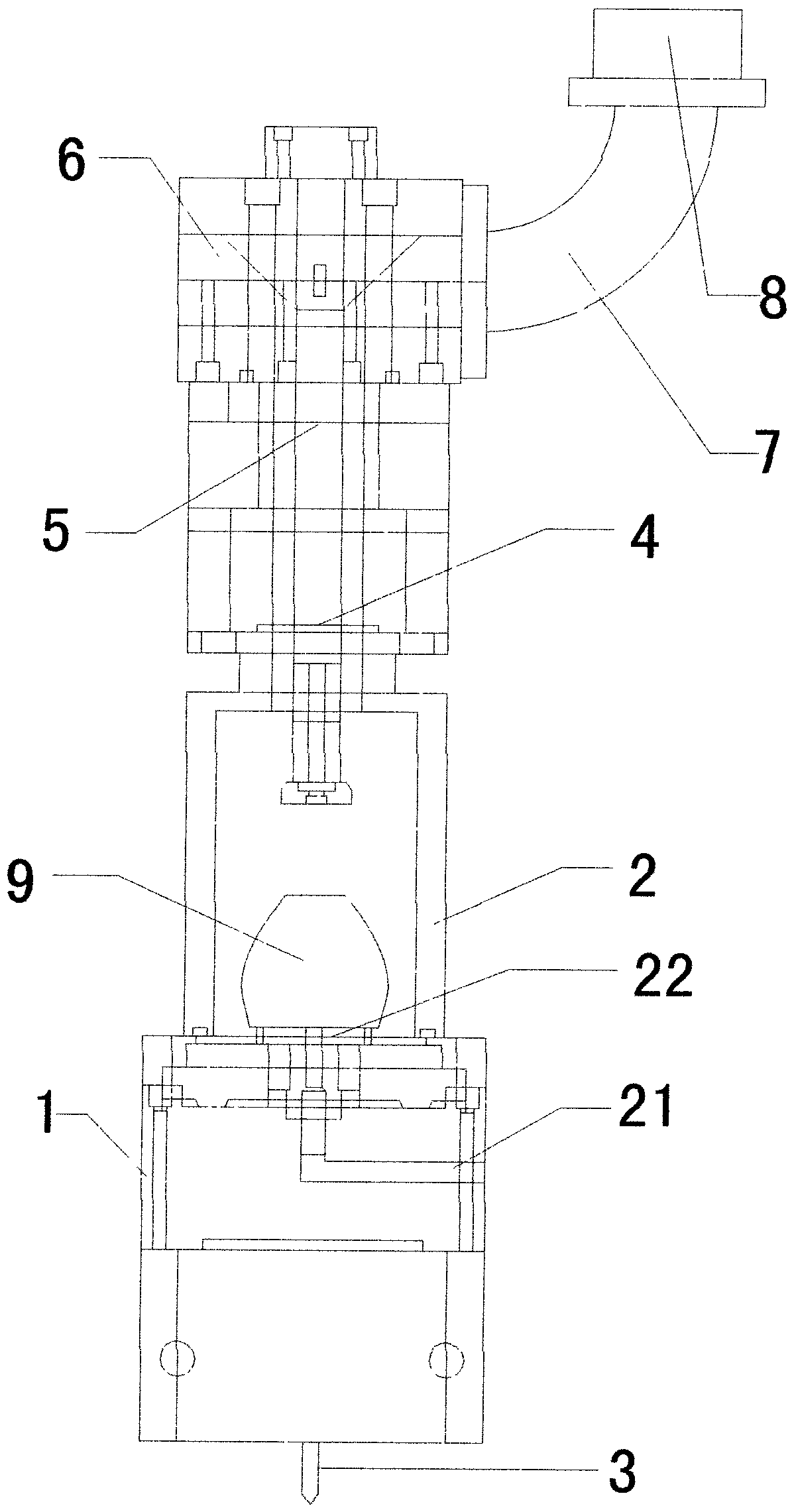

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0034] The present invention first discloses a method for forming an optical film on a workpiece. The method is a pulsed plasma chemical vapor deposition method. This embodiment takes the formation of an infrared cut-off film or an infrared transmission film as an example, and specifically includes the following steps:

[0035] a. Fix the workpiece in the sealed microwave cover, and evacuate the sealed microwave cover; the vacuum degree in the sealed microwave cover reaches 10 -1 mbar to 10 -3 Stop vacuuming at mbar;

[0036] b. Introduce oxygen into the sealed microwave cover, and introduce pulsed microwave into the sealed microwave cover. The reaction time is 10 seconds to 60 seconds, depending on the size of the workpiece; during this process, the pulsed microwave acts on the sealed microwave cover Oxygen plasma is generated by the oxygen, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com