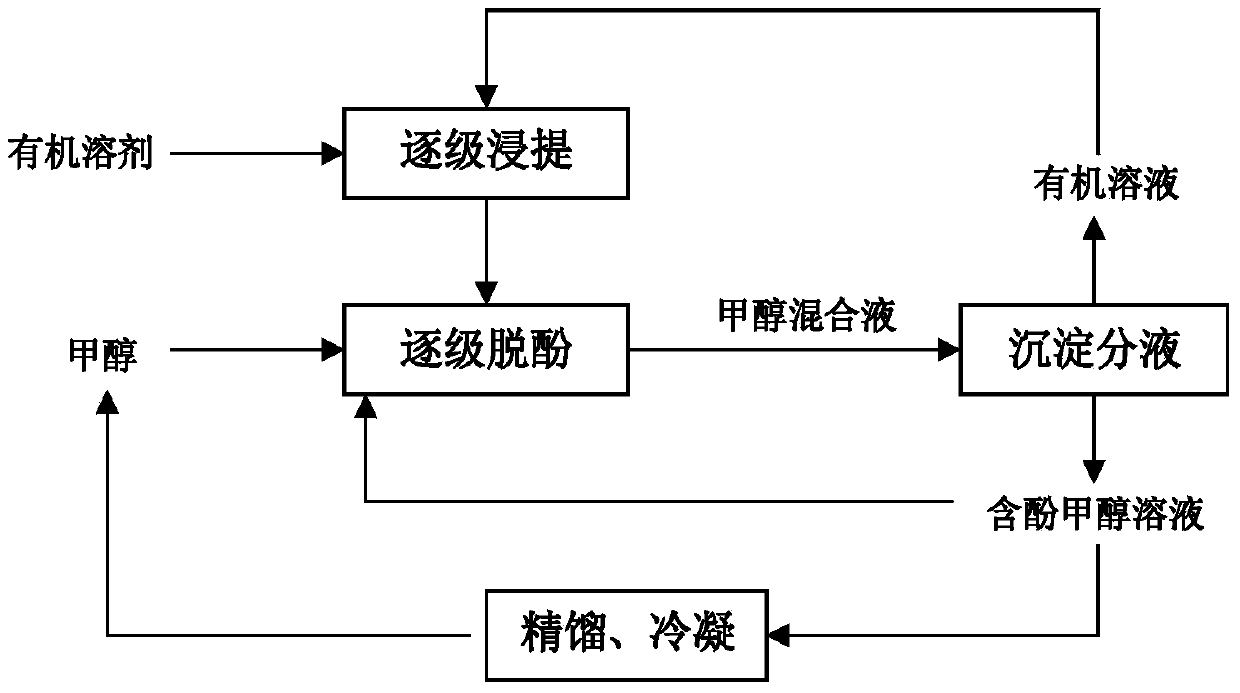

Circulating dephenolizing device and circulating dephenolizing process for producing cottonseed protein by virtue of extraction method

A technology of cottonseed protein and extraction method, which is applied in the field of circulating dephenolization equipment in the production of cottonseed protein by extraction method, can solve the problems of large heat energy consumption and large reboiler load, and achieve energy saving, loss reduction, and compact process equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

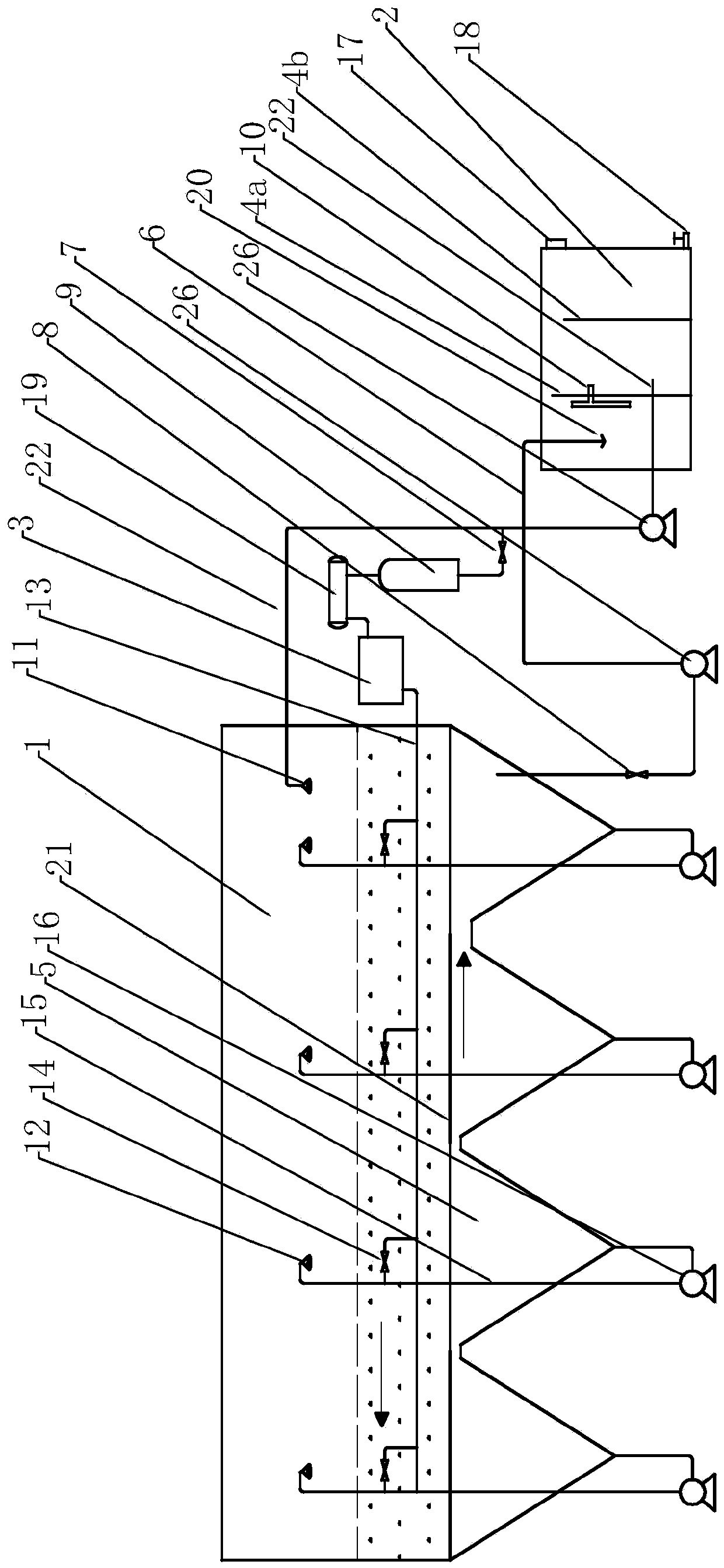

[0013] Such as figure 1 and figure 2 , Cottonseed protein circulation dephenolization device by extraction method, including a multi-stage spray extraction extractor 1, a liquid separation box 2, a rectification tower 9, a condenser 19, a methanol mother liquor tank 3 and a mother liquor pipe 13. Each stage of spray extraction leaching unit includes a spray pipe 12 , a bottom sieve tray 21 , a funnel box 5 , a spray circulation pump 16 and a spray circulation pipe 15 . The upper parts of the funnel boxes 5 at all levels are connected, and the sides are raised step by step according to the traveling direction of the material. , The mother liquor pipe 13 communicates with the spray circulation pipes 15 at all levels respectively.

[0014] An external circulation loop is formed between the extractor 1 and the liquid separation box 2, and the structure of the external circulation loop is: a regulating valve 8 is provided between the upper part of the first-stage funnel box 5 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com