Polyester material recovery and surface mechanical etching method

A polyester material and mechanical technology, which is applied in the field of polyester material recycling and surface mechanical etching, can solve the problems of poor physical properties of fibers and high recycling energy consumption, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

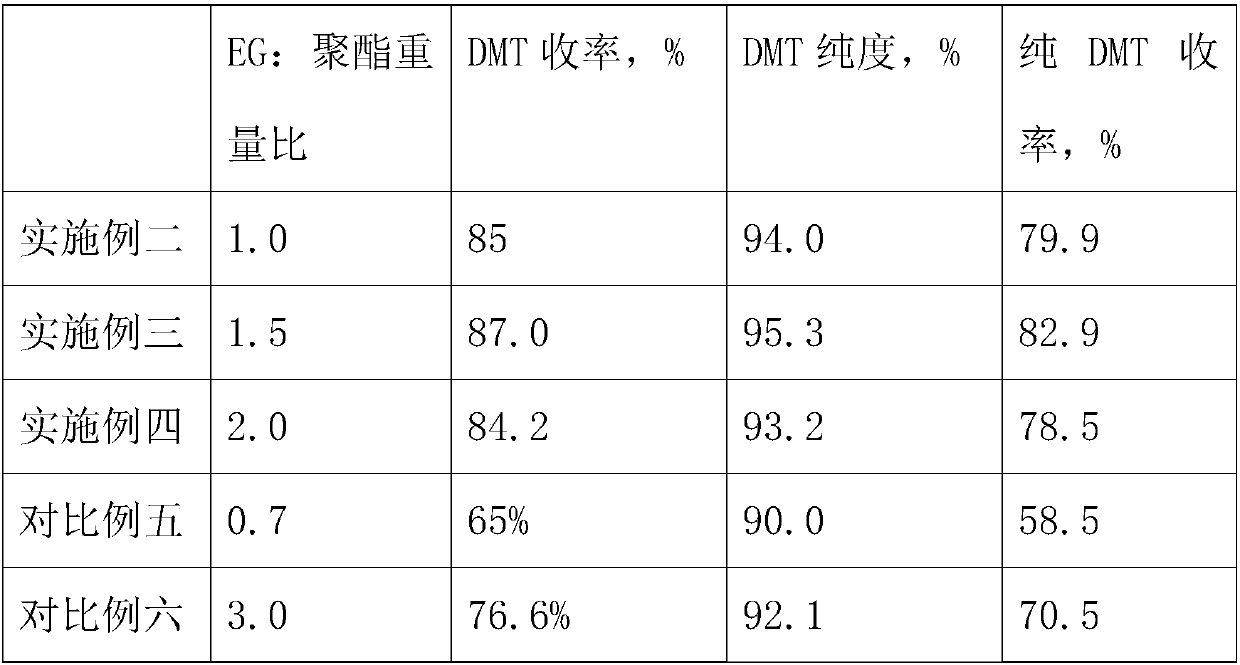

Examples

Embodiment 1

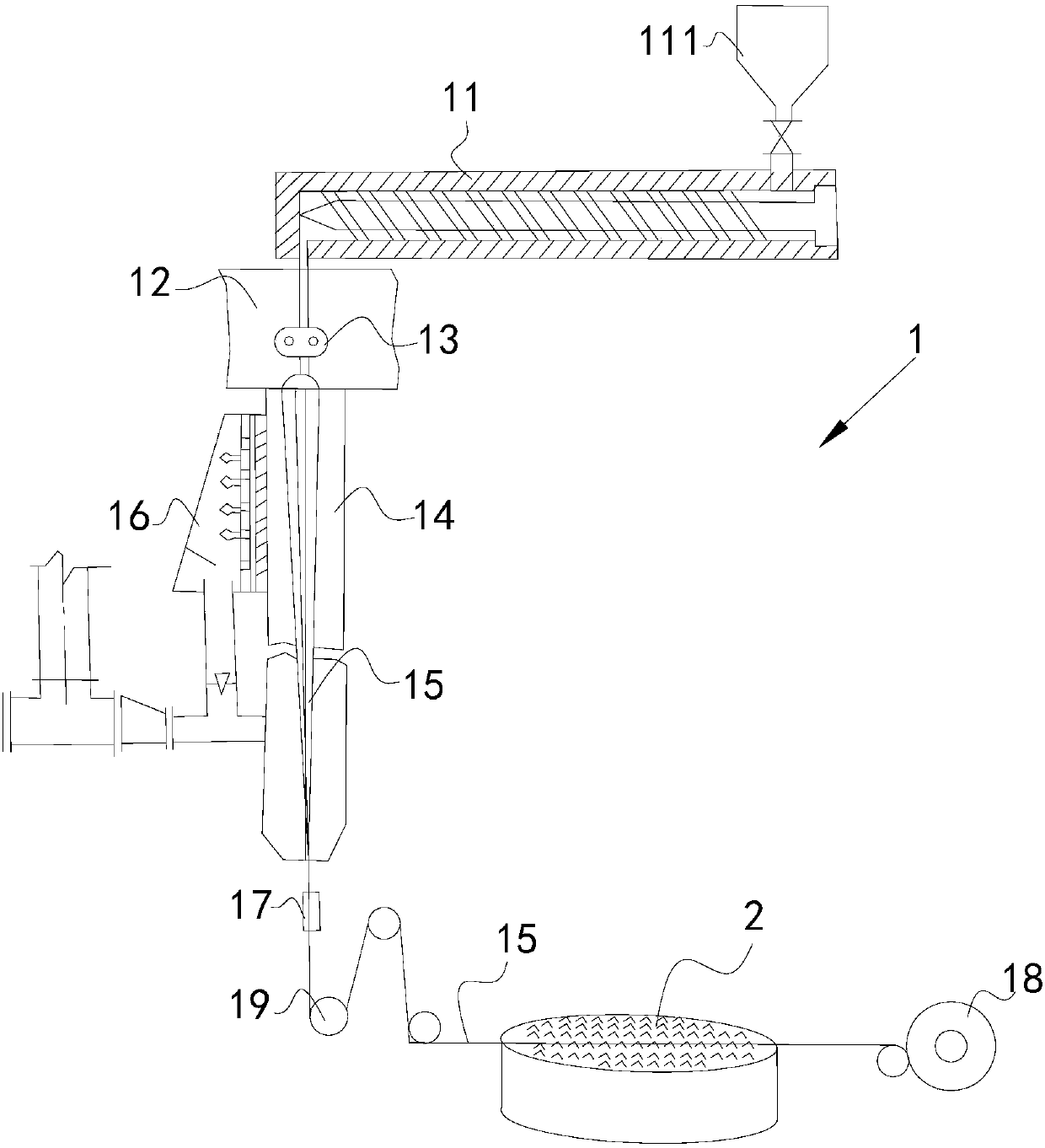

[0043] A method for polyester material recovery and surface mechanical etching, comprising the following steps:

[0044] Alcoholysis: Put 100g of waste polyester, 180g of EG, and 2.7g of potassium carbonate into the alcoholysis kettle, replace the air with nitrogen, heat up to 200°C, and alcoholyze for 3.0hr.

[0045] Removal of impurities: the above-mentioned alcoholyzate is cooled to 170°C, and filtered through a 100-mesh filter to remove solid impurities. The solid impurities are washed with 90g of hot EG at 170°C, and the washed EG is returned to the alcoholysis tank for alcoholysis of the next batch of waste polyester.

[0046] Exchange reaction: add 180 g of methanol and 2.7 g of potassium carbonate to the above alcoholyzate, keep the temperature at 75° C., and the reaction time is 1.0 hr.

[0047] Crude extraction: the temperature of the above-mentioned transesterification product is lowered to 40°C, and DMT crystallizes out. A crude DMT filter cake was obtained by va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com