Emamectin benzoate purifying method

A purification method, emamectin benzoate technology, applied in chemical instruments and methods, sugar derivatives, organic chemistry, etc., can solve the problems of excessive acetone content, low product purity, low recrystallization yield, etc., to reduce recovery energy Consumption, increase economic benefits, reduce the effect of solvent loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

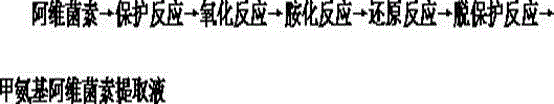

Method used

Image

Examples

Embodiment 1

[0029] Take 500ml of emamectin extract (concentration 700mg / ml), raise the temperature to 38±2°C, add 75ml of saturated sodium chloride solution at 15% (V / V), stir thoroughly for 40 minutes, and let stand for 20 minutes , divide water and filter to obtain 460ml of emamectin isopropyl acetate dehydration solution (concentration 750mg / ml), add 3000ml of isopropyl acetate solvent, dilute the dehydration solution to obtain 3450ml dilution solution (concentration 100mg / ml) ,spare.

[0030] Put 3450ml of the above diluent (concentration: 100mg / ml) into the macroporous resin LX1600 tank at a temperature of 20-25°C at a speed of 2.0BV / h until the feed liquid is completely fed.

[0031] After feeding the feed liquid, wash it with purified water until it is colorless, and elute it with dichloroethane at a rate of 1.5BV / h. Aminoabamectin dichloroethane eluent, liquid phase detection when the concentration of emamectin reaches about 200ug / ml, stop elution, combined eluent total 1620ml (c...

Embodiment 2

[0037]Take 550ml of emamectin extract (concentration 700mg / ml), raise the temperature to 38±2°C, add 93.5ml of saturated sodium chloride solution at 17% (V / V), stir for 30 minutes, and let stand for 15 minutes , divide water and filter to obtain 500ml of emamectin isopropyl acetate dehydration solution (concentration 770mg / ml), add 3000ml of isopropyl acetate solvent, dilute the dehydration solution to obtain 3250ml dilution solution (concentration 120mg / ml) ,spare.

[0038] Put 3250ml of the above diluent (concentration: 120mg / ml) into the macroporous resin LX1600 tank at a temperature of 20-25°C at a speed of 3.0BV / h until the feed liquid is completely fed.

[0039] After feed liquid enters, top wash with purified water to colorless, carry out elution with dichloroethane, elution speed is carried out with 2.0BV / h, after high-performance liquid checks emamectin peak appears, collect formazan Aminoabamectin dichloroethane eluent, liquid phase detection when the concentration ...

Embodiment 3

[0045] Take 600ml of emamectin extract (concentration 700mg / ml), raise the temperature to 38±2°C, add 120ml of saturated sodium chloride solution at 20% (V / V), stir for 40 minutes, and let stand for 30 minutes. Divide the water and filter to obtain 540ml of emamectin isopropyl acetate dehydration solution (concentration 765mg / ml), add 3100ml of isopropyl acetate solvent, dilute the dehydration solution to obtain 3480ml dilution solution (concentration 115mg / ml), spare.

[0046] Put 3480ml of the above diluent (concentration: 115mg / ml) into the macroporous resin LX1600 tank at a temperature of 20-25°C at a speed of 4.0BV / h until the feed liquid is completely fed.

[0047] After feed liquid enters, top wash with purified water until colorless, carry out elution with dichloroethane, elution speed is carried out with 2.5BV / h, after high-performance liquid checks emamectin peak appears, collect formazan Aminoabamectin dichloroethane eluent, liquid phase detection when the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com