Rare earth wastewater treatment and recovery process

A wastewater and rare earth technology, which is applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of inability to recover rare earth elements in wastewater, large amount of rare earth process wastewater, and unsatisfactory effluent quality. Achieve the effect of easy industrial production, low processing cost, and reduced mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

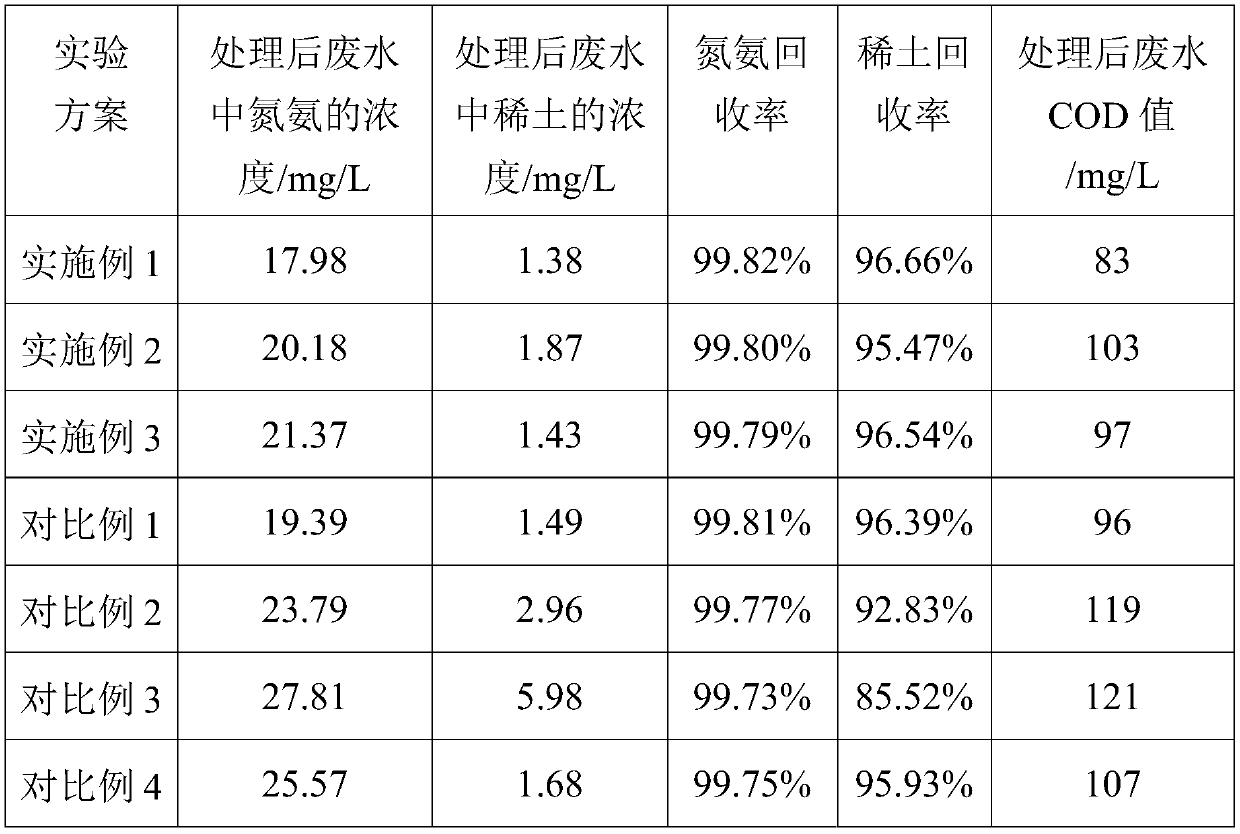

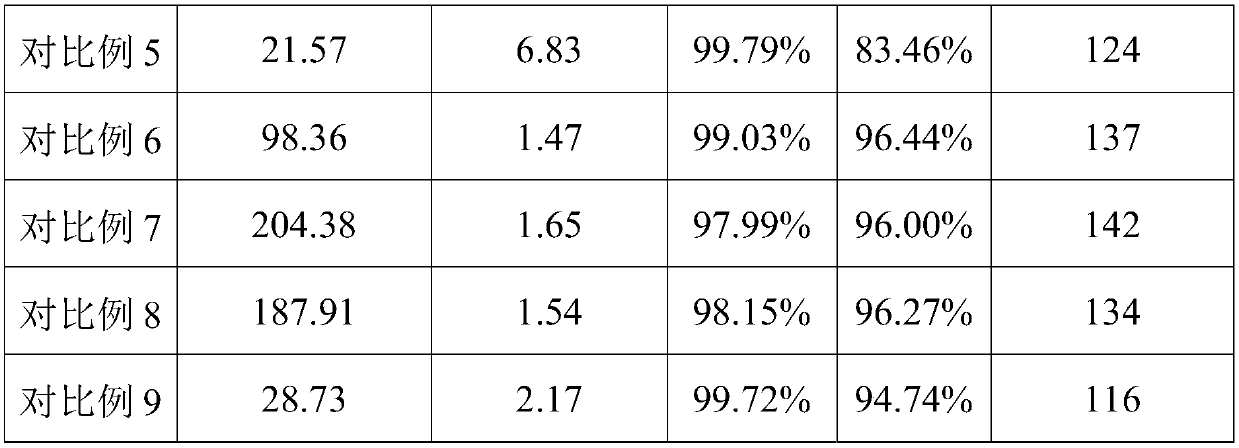

Examples

Embodiment 1

[0033] A process for the treatment and recovery of rare earth wastewater, including the following steps:

[0034] (1) Rare earth wastewater is processed by quartz sand filter, microporous filter and ultrafiltration device in order to obtain rare earth wastewater from which suspended solids and small particles are removed;

[0035] The pore size of the microporous membrane of the microporous filter is 0.1-0.2 μm and the material is polypropylene; the pore size of the ultrafiltration membrane of the ultrafiltration device is 0.01-0.02 μm and the material is polyvinylidene fluoride.

[0036] (2) Adjust the pH of wastewater to 3 by acid or alkali, and then obtain concentrated liquid and filtrate through nanofiltration device;

[0037] The membrane composition of the nanofiltration device is three-stage nanofiltration, wherein the pore size of the first-stage nanofiltration membrane is 3-4nm, the pore size of the second-stage nanofiltration membrane is 1.5-3nm, and the pore size of the thir...

Embodiment 2

[0046] A process for the treatment and recovery of rare earth wastewater, including the following steps:

[0047] (1) Rare earth wastewater is processed by quartz sand filter, microporous filter and ultrafiltration device in order to obtain rare earth wastewater from which suspended solids and small particles are removed;

[0048] The pore size of the microporous membrane of the microporous filter is 0.2-0.3 μm, and the material is polypropylene material; the pore size of the ultrafiltration membrane of the ultrafiltration device is 0.02-0.03 μm, and the material is polyvinylidene fluoride material.

[0049] (2) Adjust the pH of wastewater to 3.5 by acid or alkali, and then obtain concentrated liquid and filtrate through nanofiltration device;

[0050] The membrane composition of the nanofiltration device is three-stage nanofiltration, wherein the pore size of the first-stage nanofiltration membrane is 3-4nm, the pore size of the second-stage nanofiltration membrane is 1.5-3nm, and the...

Embodiment 3

[0058] A process for the treatment and recovery of rare earth wastewater, including the following steps:

[0059] (1) Rare earth wastewater is processed by quartz sand filter, microporous filter and ultrafiltration device in order to obtain rare earth wastewater from which suspended solids and small particles are removed;

[0060] The pore size of the microporous membrane of the microporous filter is 0.3-0.4 μm, and the material is polypropylene material; the pore size of the ultrafiltration membrane of the ultrafiltration device is 0.01-0.02 μm, and the material is polyvinylidene fluoride material.

[0061] (2) Adjust the pH of wastewater to 4 by acid or alkali, and then obtain concentrated liquid and filtrate through nanofiltration device;

[0062] The membrane composition of the nanofiltration device is three-stage nanofiltration, wherein the pore size of the first-stage nanofiltration membrane is 3-4nm, the pore size of the second-stage nanofiltration membrane is 1.5-3nm, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com