A method for purifying printing and dyeing sewage with dynamic three-dimensional electrocatalysis of nano-microbubbles

A nano-micro-bubble, catalytic purification technology, applied in electrochemical water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. Taking advantage of the mass transfer efficiency of the reactor and the insufficient hydraulic exchange between the electrodes and the sewage to be treated, the effects of outstanding electrocatalytic activity, good heat resistance and small footprint are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

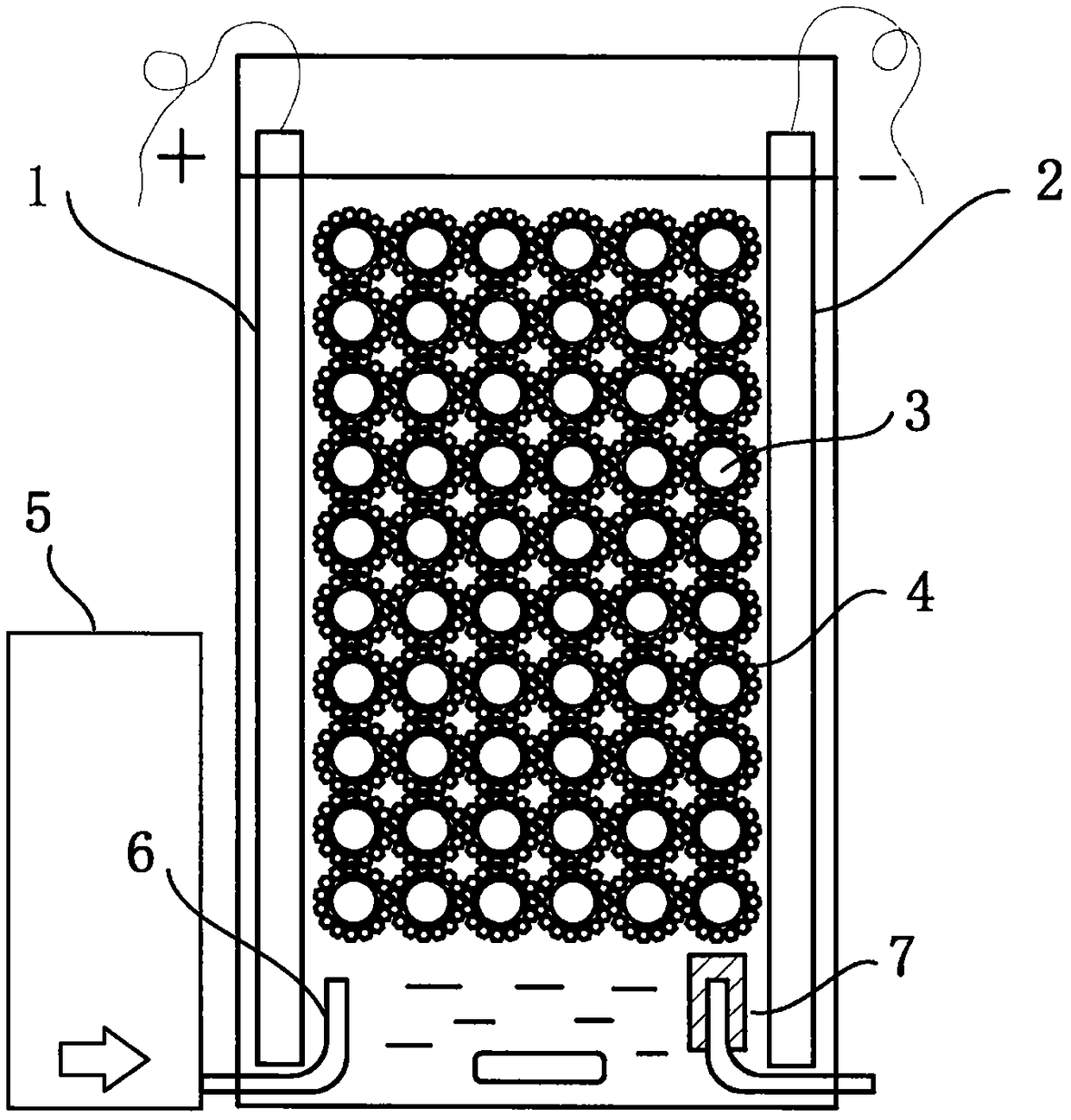

[0031] Such as figure 1 As shown, a method for the dynamic three-dimensional electrocatalytic purification of printing and dyeing sewage with nano-microbubbles, the composition of the reaction device is as follows: the anode (1) and the cathode (2) are placed in the electrolytic cell, and are respectively connected to the positive and negative poles of the DC power supply through wires Titanium oxide particles (3) are placed in the electrolytic cell, and can be attached to the surface of the bubbles to form a microbubble emulsion under aeration conditions, and one side of the bottom of the electrolytic cell is connected with the nano-microbubble aeration device (5), and through The head (6) aerates the wastewater, and the other side is provided with a microfiltration head (7), so that the titanium oxide nanoparticles (4) can be separated from the water phase smoothly after the reaction.

no. 2 example

[0033] A certain printing and dyeing wastewater is treated with the reaction device described in the first embodiment. The water quality parameters of the wastewater are: SS 68.7mg / L, pH value 3.5, conductivity 800μs / cm, COD Cr 278mg / L, N-NH 3 31.2mg / L, chromaticity 50.

[0034]First, remove the suspended particles in the wastewater by sand filtration, reduce its SS value to 45mg / L, adjust the pH value to approximately equal to 7 with sodium hydroxide, and add an appropriate amount of sodium sulfate to make the conductivity of the printing and dyeing wastewater 1200μs / cm. Perform aeration treatment to fully mix the printing and dyeing wastewater with the electrolyte, and add it to the electrolytic cell with an inert form-stable electrode as the anode and a stainless steel plate as the cathode, add 500mg / L titanium dioxide particles to the electrolytic cell, and start nano-microbubble aeration The device pre-oxygenates the printing and dyeing wastewater through the lower aerat...

no. 3 example

[0036] A certain printing and dyeing wastewater is treated with the reaction device described in the first embodiment. The water quality parameters of the wastewater are: SS 125mg / L, pH value 4.7, conductivity 725μs / cm, COD Cr 306mg / L, N-NH 3 10.4mg / L, chromaticity 25.

[0037] The dosage of titanium dioxide particles in the electrocatalysis process is 700mg / L, and the electrocatalytic current density is 12.5mA / cm 2 , the rest of the process and conditions are the same as those in Embodiment 2, and will not be repeated here.

[0038] After 40 minutes of electrocatalytic treatment, the effluent quality is as follows: SS 5.7mg / L, pH 5.0, conductivity 216μs / cm, COD Cr 22.2mg / L, N-NH 3 1.2mg / L, color 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com