Construction method of Y-shaped cast steel combined with steel pipe column in subway station

A subway station and construction method technology, applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve problems such as processing technology, welding quality, lifting and installation difficulties, time-consuming and labor-intensive concrete construction, and uncompacted concrete in pipe columns, etc. Achieve the effects of being conducive to safety management, simple and fast construction methods, and obvious social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

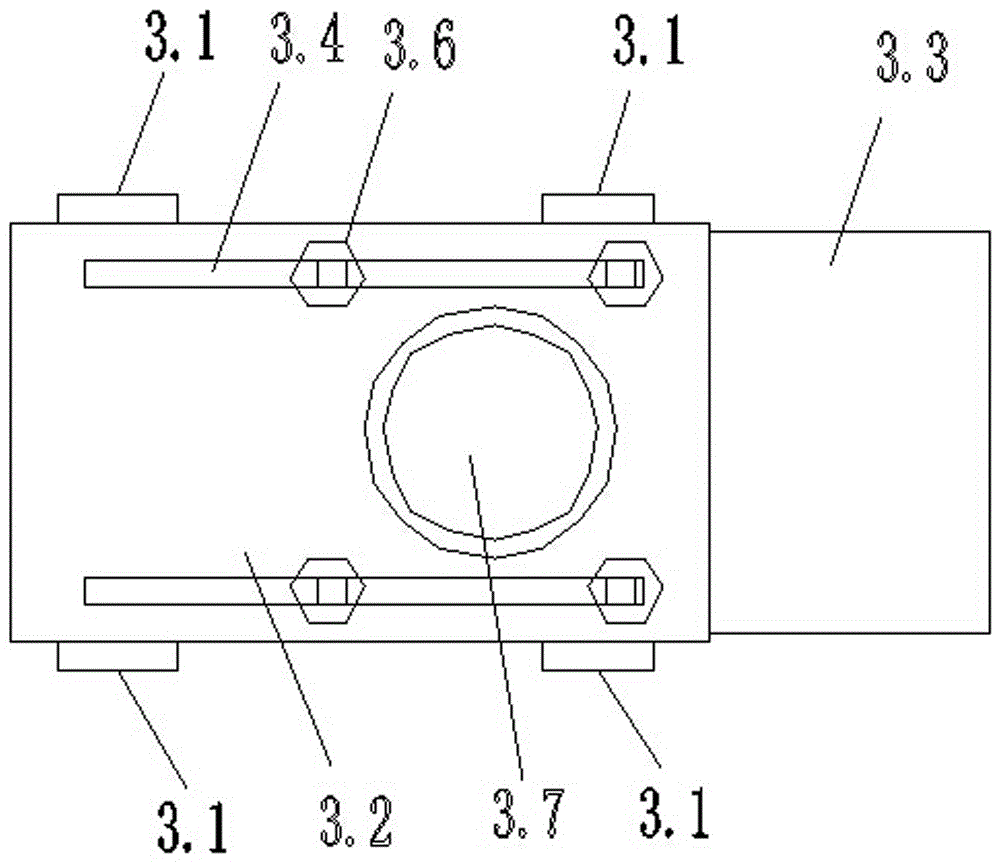

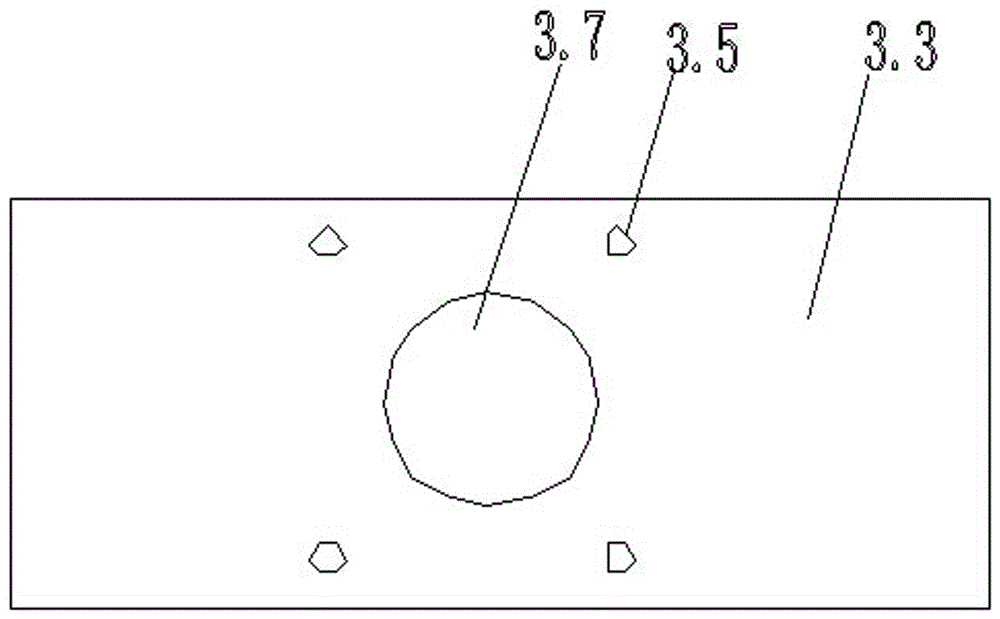

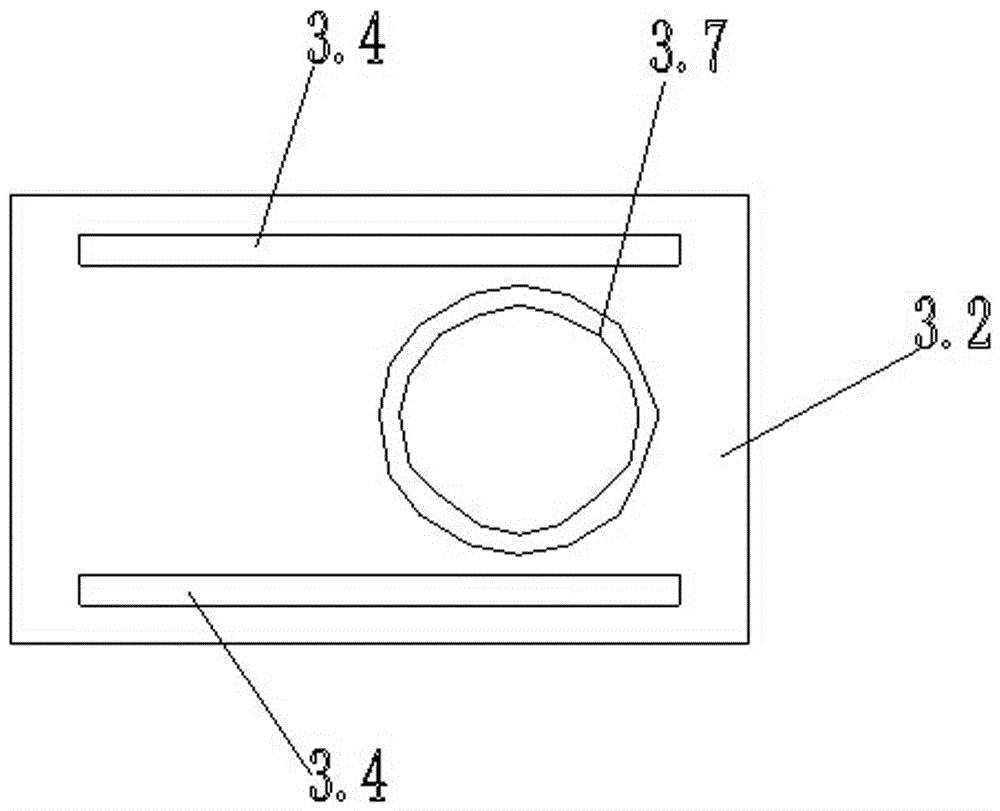

[0062] A construction method for a Y-shaped cast steel combined steel pipe column in a subway station, comprising the following steps:

[0063] Step 1. Design and processing of Y-shaped cast steel combined with steel pipe column

[0064] The cast steel section 11 on the upper part of the Y-shaped cast steel combined with the steel pipe column is formed by casting two bifurcated sections 12 and a vertical node section 13 respectively, and then assembled and welded at the construction site. The material is G20Mn5N, the wall thickness is 80mm, and the bifurcated node position The wall thickness is 130mm, and the angle between the two bifurcated sections is 70°; the steel pipe section 14 under the Y-shaped cast steel combined steel pipe column is welded by several steel pipe sections, the material is Q345B, the steel pipe diameter is 1200mm, and the wall thickness is 30mm; This structure can bear 2,000 tons of vertical pressure on a single axis.

[0065] The upper cast steel sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com