Engine exhaust pipe heat shield

A technology for engines and exhaust pipes, which is applied in the direction of engine components, machines/engines, exhaust devices, etc., can solve problems such as the inability to effectively block high-temperature heat radiation of exhaust pipes, and achieve improved working environment temperature and good heat insulation effect , the effect of preventing catastrophic events

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

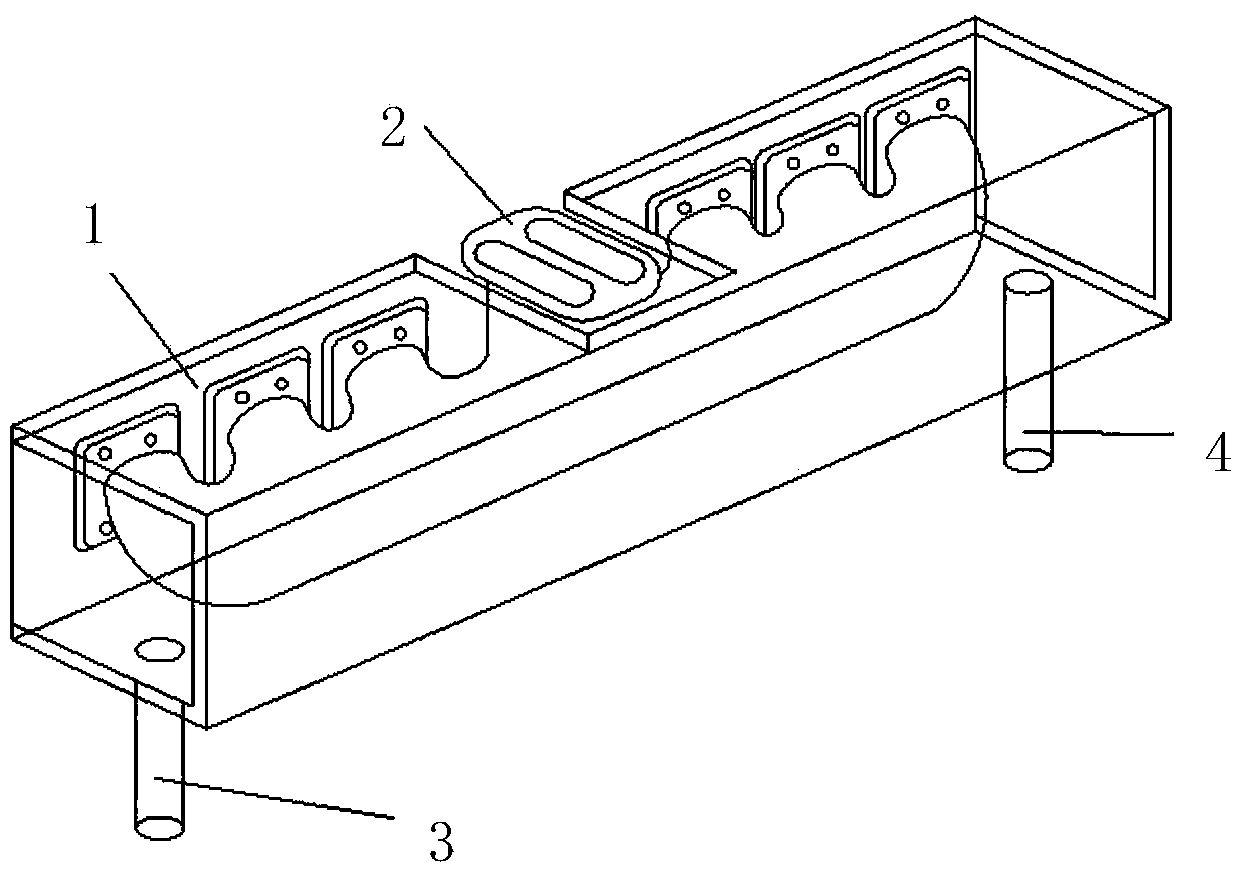

[0013] Embodiment one: if figure 1 As shown, the engine exhaust pipe heat shield is made of a hollow interlayer sleeve 1 that fully seals the engine exhaust pipe 2, and the hollow interlayer sleeve 1 has a cooling water inlet 3 and a cooling water outlet 4 connected to the engine cooling water cycle. The heat of the hollow interlayer sleeve 1 can be continuously taken away by the engine cooling water circulation, and its surface temperature can be kept below 70 degrees to achieve the purpose of isolating the high-temperature heat source of the engine exhaust pipe, preventing fuel fire accidents and reducing the temperature of the engine compartment. Simple and effective heat shield for engine exhaust pipe insulation.

Embodiment 2

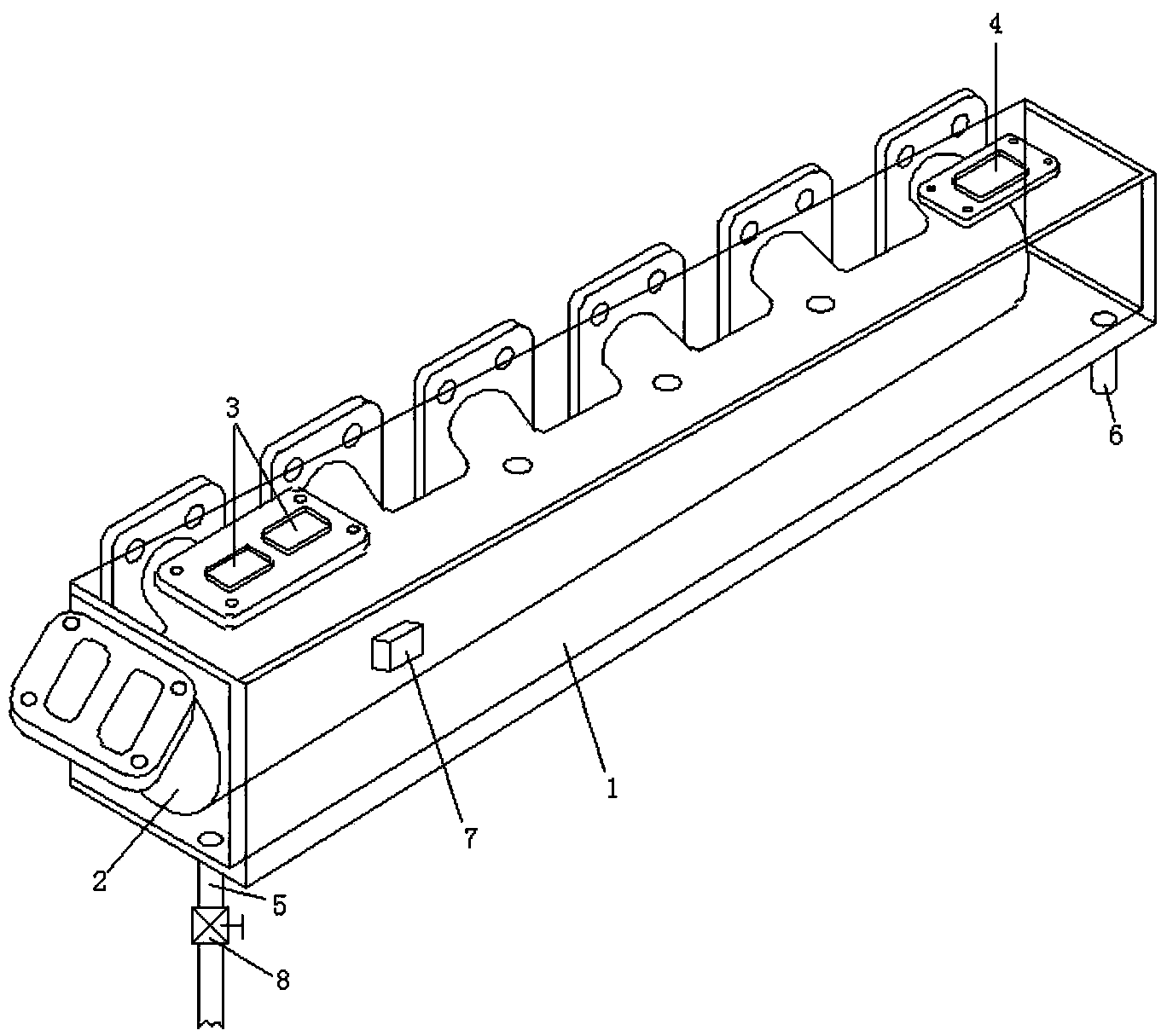

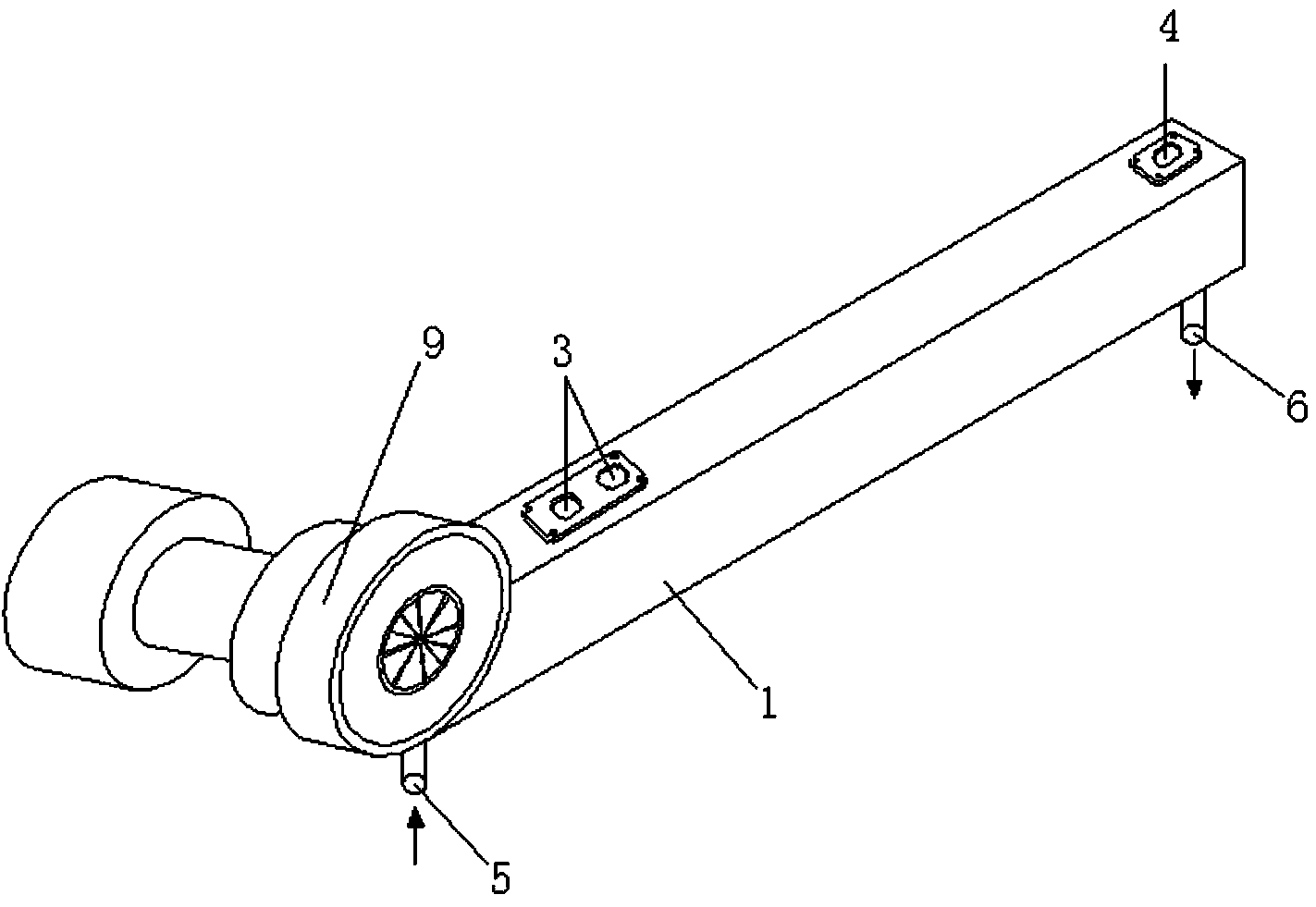

[0014] Embodiment two: if figure 2 , image 3 , Figure 4 As shown; the engine exhaust pipe heat shield is composed of a hollow interlayer sleeve 1 fully sealed engine exhaust pipe 2 and a turbocharger connecting pipe 9, and there are 2 groups of cooling water inlets and cooling water outlets on the hollow interlayer sleeve 1 , the cooling water inlet 3 and the cooling water outlet 4 are connected to the circulating cooling water of the engine, and the cooling water inlet 5 and the cooling water outlet 6 are connected to supplementary cooling water through the solenoid valve 8. When the water circulation is not enough to reduce the temperature of the hollow interlayer jacket 1, start supplementary cooling water, such as figure 2 , image 3 , Figure 4 As shown, a temperature sensor 7 is provided on the hollow interlayer sleeve 1, and the electromagnetic water valve 8 in the supplementary cooling water pipeline is controlled by a control circuit. The setting of the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com