A micro-combustor for catalytic reforming of liquid fuel

A liquid fuel, micro-combustion technology, applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of low comprehensive heat utilization efficiency, low combustion efficiency, unstable combustion, etc., to increase the catalyst area, increase the heat exchange area, The effect of efficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention in any way:

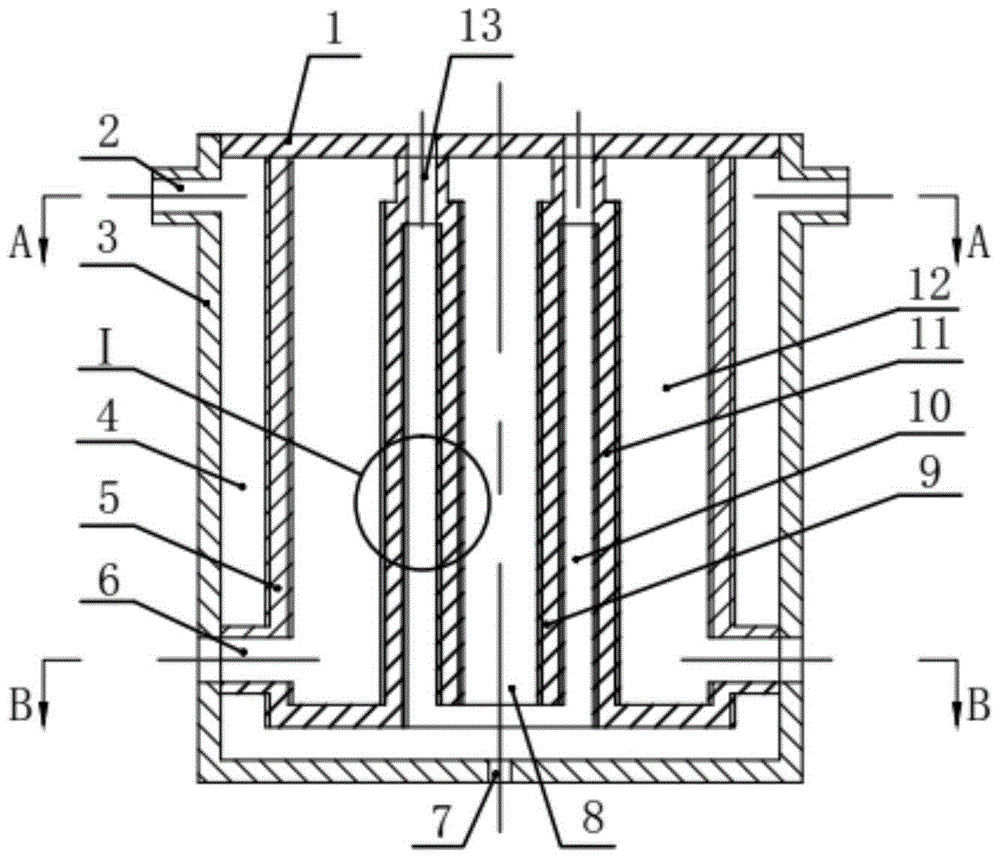

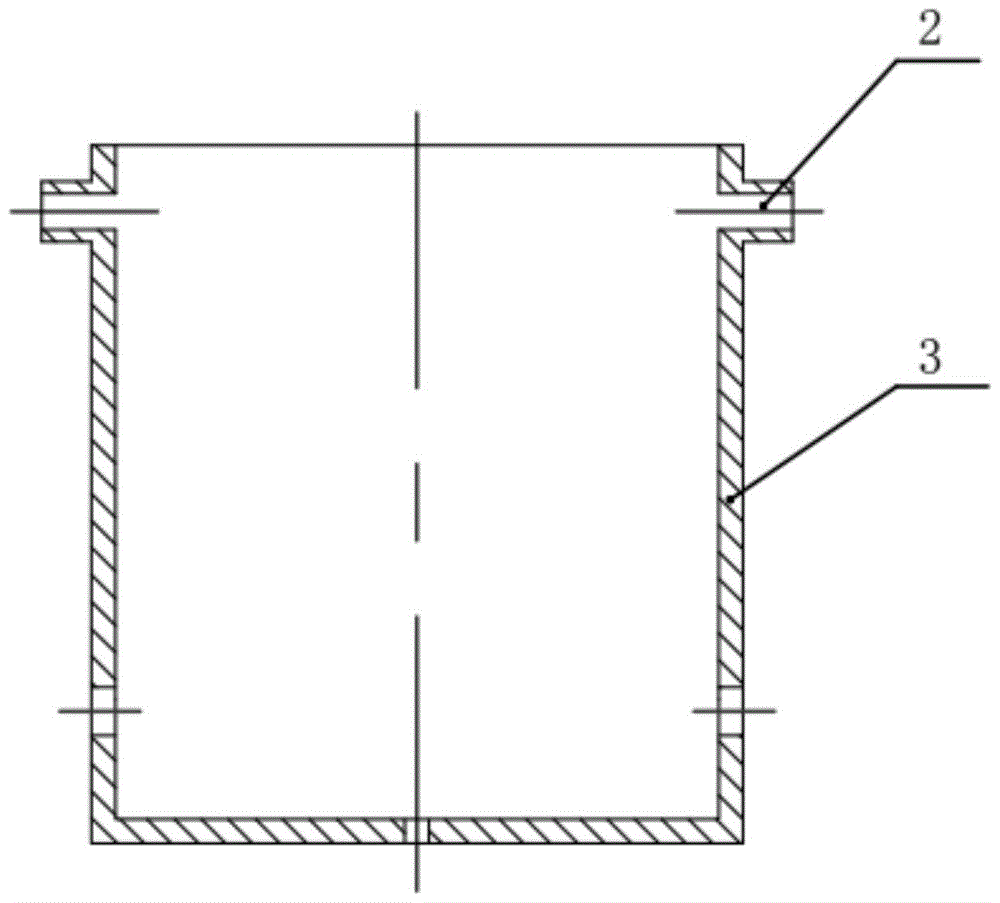

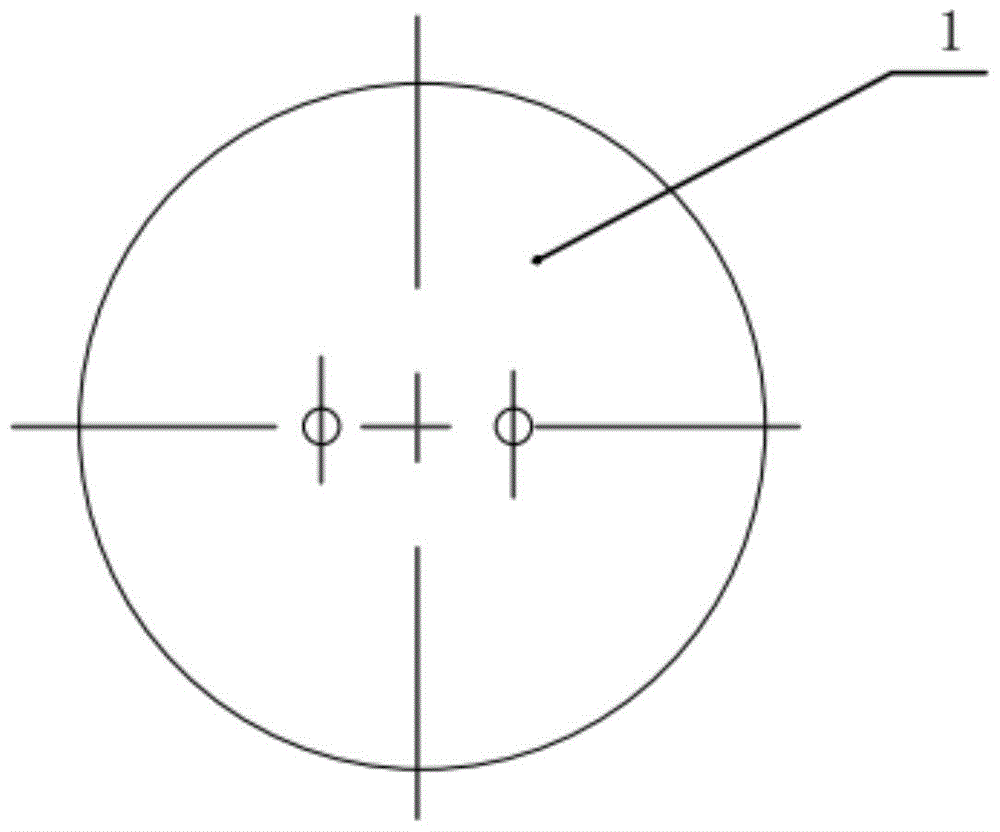

[0030] Such as Figure 1-7 As shown, the embodiment of the present invention provides a specific embodiment of a liquid fuel catalytic reforming micro-combustor, including a circular top cover plate 1, a housing 3 integrally connected with the top cover plate 1, and the top cover plate 1 is provided with a There are two symmetrical fuel inlet 13 holes, two symmetrical air inlet 2 holes are opened on the upper side of the housing 3, two symmetrical exhaust holes are opened on the lower side of the housing 3, and the center of the bottom of the housing 3 is opened There is an igniter hole 7; the inner sleeve 9, the middle sleeve 11 and the outer sleeve 5 are installed inside the housing 3, and the air passage 4 is arranged between the housing 3 and the outer sleeve 5, and is connected to the air inlet 2 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com