Testing method for simulating launching impact overload in chamber

A test method and technology of simulating chambers, applied in the field of testing, can solve problems such as complex process, many uncontrollable factors, and difficulty in grasping performance evolution behavior, so as to achieve the effect of simple method and avoiding complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

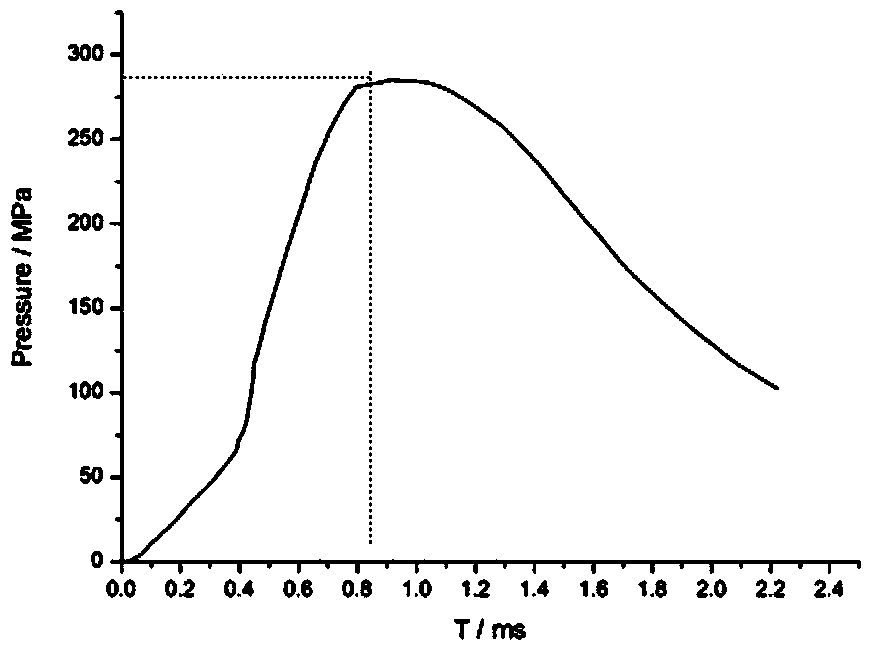

[0031] Taking the simulation of the firing process of a gun as an example, the p-t curve of the chamber pressure when the gun is launched is as figure 2 As shown, the loading time for the chamber pressure to reach the peak is 0.85ms, and the maximum chamber pressure is 285MPa.

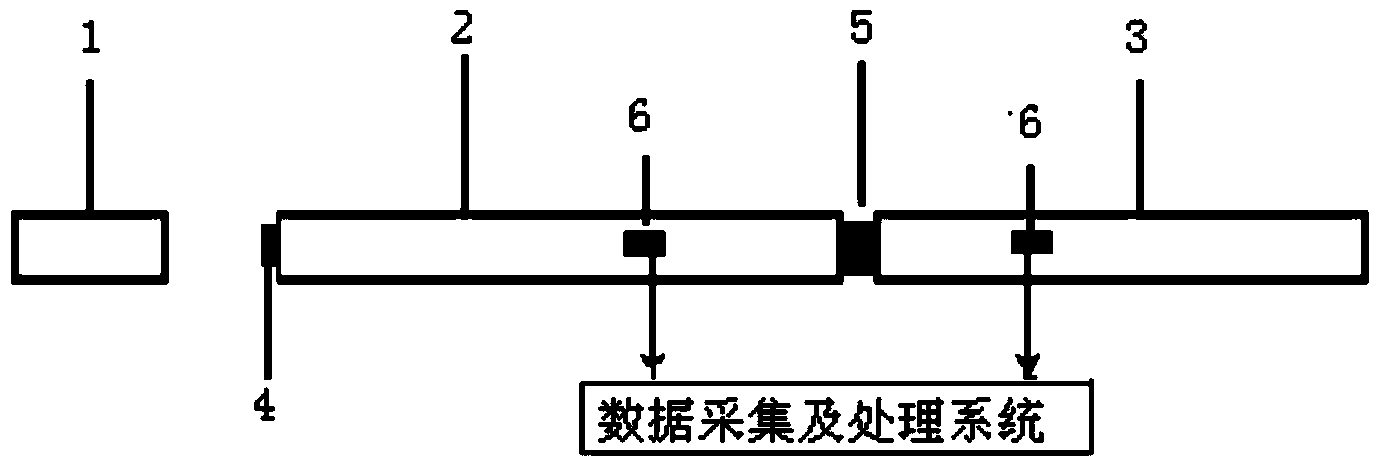

[0032] The striking rod 1, the loading rod 2 and the transmission rod 3 are all cylindrical rods with a diameter of 80mm, the material is 40CrNiMoA, the yield strength is 835MPa, and the density is 7.85×10 3 kg / m 3 , The longitudinal wave velocity is 5000m / s. The length of the striking rod 1 is 2000 mm, the length of the loading rod 2 is 4000 mm, and the length of the transmission rod 3 is 4000 mm. The shaper 4 is a brass sheet of Φ30mm×3mm. By type It is calculated that the predetermined strike speed of the stick 1 is 14.5m / s. The tested sample 5 is a cylindrical resin-based carbon fiber reinforced composite material with an outer diameter of 74mm, an inner diameter of 60mm, and a length of 75mm.

[00...

Embodiment 2

[0037] In the loading process of the bore pressure simulated in this embodiment, the maximum bore pressure is 300 MPa, and the loading time before the bore pressure reaches the peak value is 0.45 ms.

[0038] The striking rod 1, the loading rod 2 and the transmission rod 3 are all cylindrical rods with a diameter of 100mm, the material is 37CrNi3, and the yield strength is 980MPa. The length of the striking rod 1 is 1200 mm, the length of the loading rod 2 is 3500 mm, and the length of the transmission rod 3 is 3500 mm. The shaper 4 is a brass sheet of Φ40mm×4mm. By type It is calculated that the predetermined strike speed of the stick 1 is 15.3 m / s. The tested sample 5 is the same as the first embodiment.

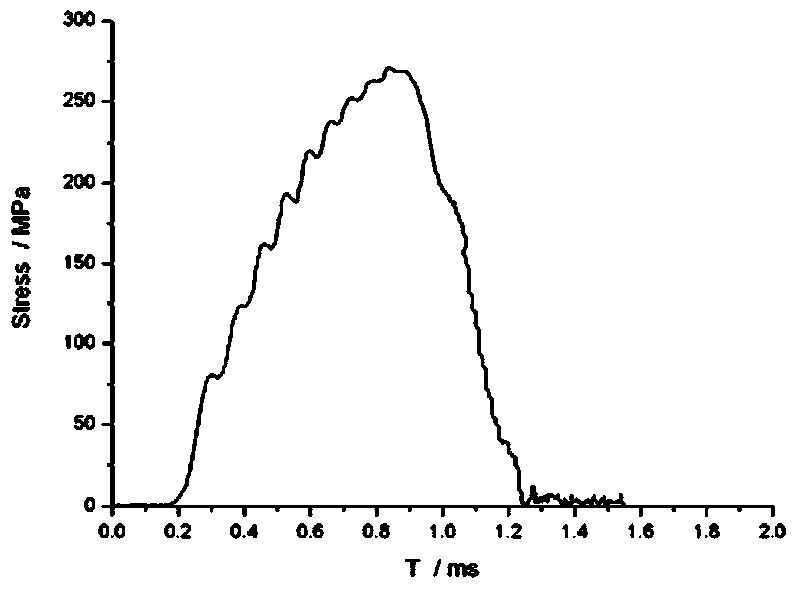

[0039] The striking rod 1 is driven by 2.4Mpa high-pressure gas, and the measured striking speed is 15.6m / s. The loading stress wave waveform measured by the test is as Figure 5 As shown, the maximum loading intensity of the loading stress wave is 302 MPa, and the loading ...

Embodiment 3

[0041] In the loading process of the bore pressure simulated in this embodiment, the maximum bore pressure is 500 MPa, and the loading time before the bore pressure reaches the peak is about 0.3 ms.

[0042] The striking rod 1, the loading rod 2 and the transmission rod 3 are all cylindrical rods with a diameter of 110mm, the material is 35CrMnSiA, and the yield strength is 1280MPa. The length of the striking rod 1 is 800 mm, the length of the loading rod 2 is 3200 mm, and the length of the transmission rod 3 is 3200 mm. The shaper 4 is a brass sheet of Φ60mm×6mm. By type It is calculated that the predetermined strike speed of the stick 1 is 25.5m / s. The tested sample 5 is a cylindrical resin-based carbon fiber reinforced composite material with an outer diameter of 70 mm, an inner diameter of 20 mm, and a length of 50 mm.

[0043] The driving source is ballistic gunpowder gas, which is launched with a 120mm smoothbore barrel. There are two nylon elastic bands on the striking r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com