Three-dimensional circuit manufacturing method and thermosetting spraying solution

A production method and technology of three-dimensional circuits, which are applied in the fields of printed circuit manufacturing, printed circuits, coatings, etc., can solve the problems of inability to manufacture plastic parts, integrate SLS process, and cannot meet the requirements of laser surface activation, so as to reduce the cost of industrial popularization. , Not limited by shape, meet the requirements of laser activation and conductive circuit forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the drawings. It should be emphasized that the following description is only exemplary, and is not intended to limit the scope of the present invention and its application.

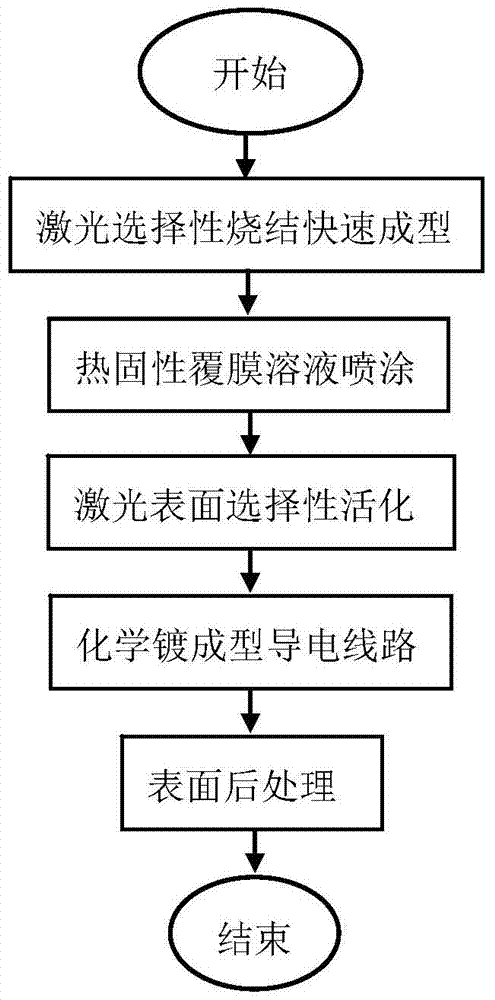

[0030] In some embodiments, a method for making a three-dimensional circuit is figure 1 As shown, the following steps are included.

[0031] step one , Generate prototype parts by selective laser sintering SLS method.

[0032] The process parameters of laser selective sintering to prepare prototype parts are as follows:

[0033] Laser selective sintering equipment is used to manufacture prototype parts. Carbon dioxide infrared laser with wavelength 10.6μm and power 10W~40W can be used as sintering source, laser scanning rate is 3~5m / s, spot diameter is 0.5mm, X, Y, Z axis processing The shrinkage compensation rate X is 2.85~3.82%, Y is 2.85~3.82%, Z(0) is 2.10~3.22%, Z(300) is 1.47~2.44%, where Z(0) refers to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com