Device and method for icing prevention regulation for heat pump evaporators

A heat pump evaporator, anti-icing technology, applied in lighting and heating equipment, heating/cooling equipment, heating methods, etc., can solve the problems of reducing utilization, reducing heat pump efficiency, etc., to achieve the effect of high thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

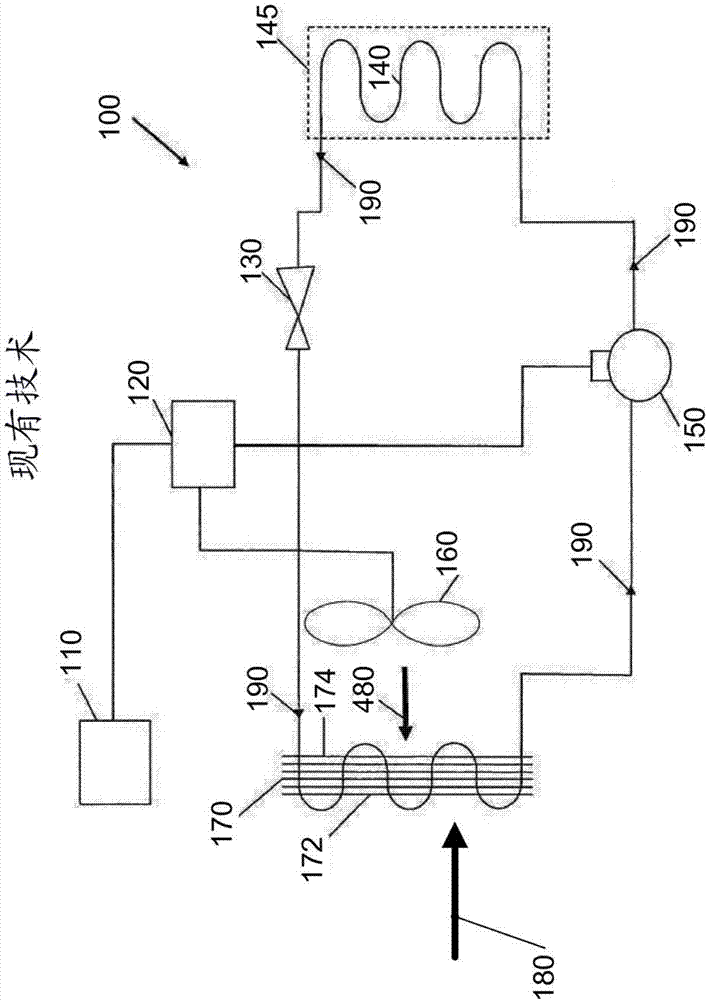

[0064] exist figure 1 The prior art heat pump 100 represented in WO2009 / 094691A1 comprises a refrigeration circuit with a heat pump evaporator 170, a compressor 150, a condenser 140 and an expansion valve 130, the latter being between the outlet of the condenser 140 and the heat pump evaporator Between 170 imports. The connection between the heat pump evaporator 170 and the compressor 150, the condenser 140, the expansion valve 130 and the heat pump evaporator 170 is provided through a refrigerant line 190 for refrigerant flow. The refrigerant liquid absorbs heat from ambient air 180 within the heat pump evaporator 170 and evaporates into a refrigerant vapor. Compressor 150 uses mechanical energy to compress the refrigerant vapor and thereby increase its temperature. In the condenser 140 the refrigerant vapor transfers its heat to the heating circuit 145, causing the refrigerant vapor to condense and become refrigerant liquid again. In the expansion valve 130, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com