Spinerette for improved spinning productivity

A spinneret, productivity technology, applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of complex and inefficient acrylic fiber methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present application will now be described with reference to the accompanying drawings, which do not limit the scope and scope of the present application. The descriptions are given by way of example and illustration only.

[0040] See the non-limiting schemes in the description below explaining the schemes herein and their various features and advantages. Descriptions of known components and processing techniques are omitted in the scheme of this paper, so as not to overwhelm the main content. The examples herein are only intended to facilitate the understanding of the ways in which the solutions herein can be implemented, so as to enable those skilled in the art to implement the solutions herein. Thus, these examples should not be interpreted as limiting the scope of the protocol herein.

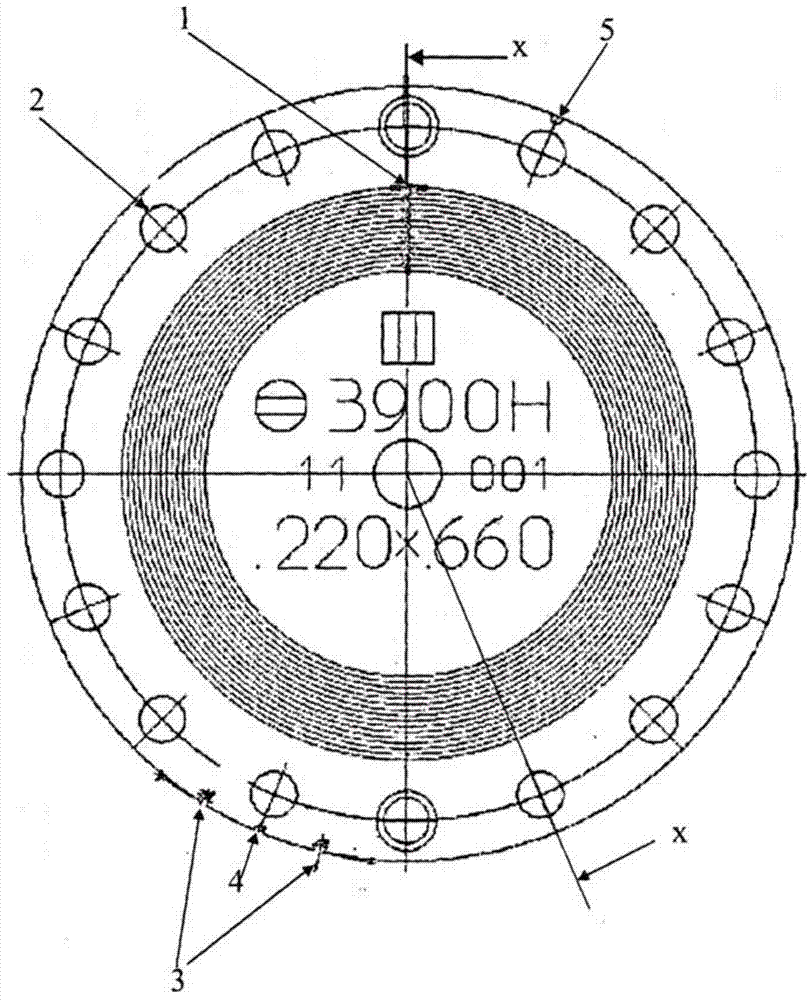

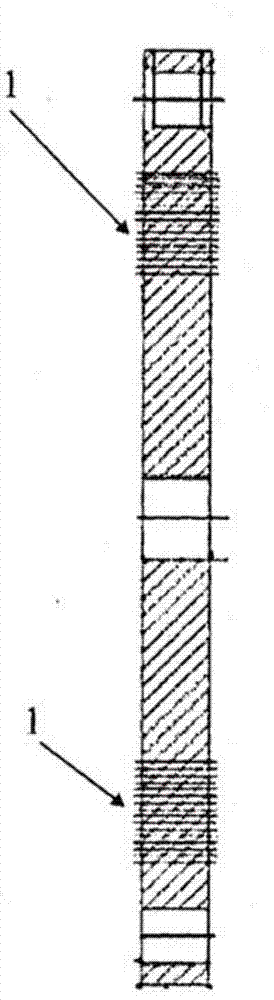

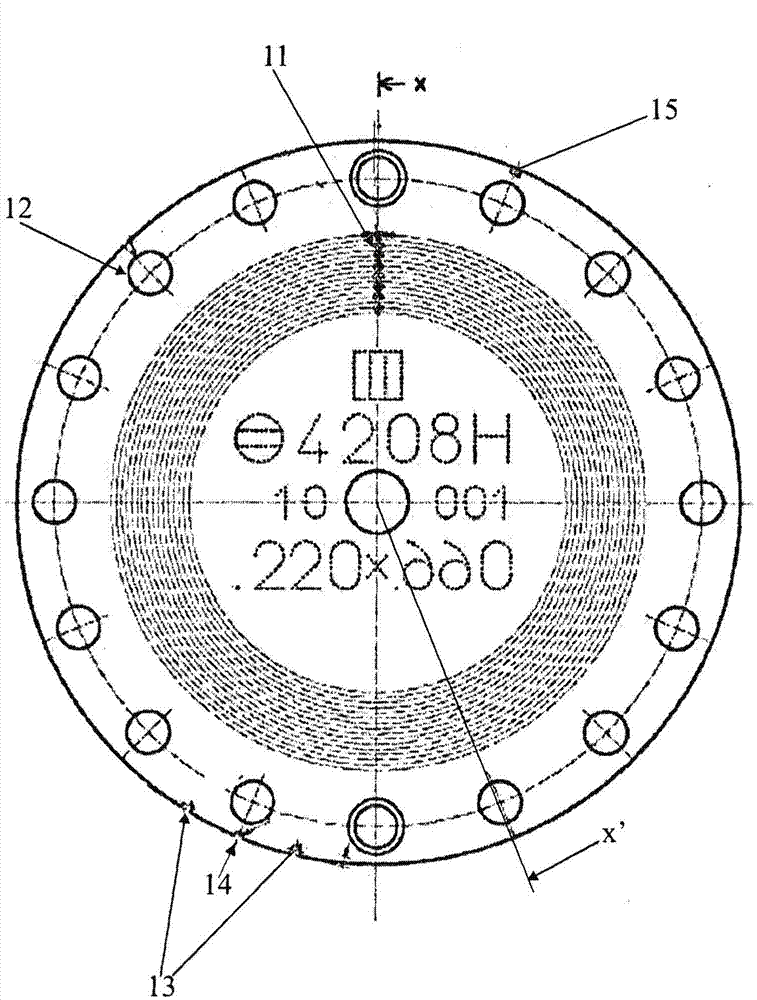

[0041] The present application contemplates an improved spinneret for extruding plastic molten polymer therefrom to form fibers. The improved spinneret has more holes distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com