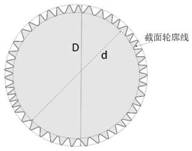

Method for preparing special-shaped cross-section carbon fiber precursor fiber, pre-oxidized fiber or carbon fiber by high-speed dry jet spinning

A technology of precursor fibers and special-shaped cross-sections, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, can solve problems such as undiscovered reports, achieve the effects of reducing production costs, stabilizing production, and increasing single-line production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073]Acrylonitrile, methyl acrylate and tie (97: 2: 1) were added in accordance with the ratio to the water (total monomer mass concentration of 25%), and the molecular weight was 80,000 by suspension polymerization. The molecular weight distribution coefficient is 1.6 PAN-type polymer (in which the coefficient of the comonomer is 3%). The polymerized PAN-based polymer was dissolved in a mixed solution of dimethyl sulfoxide solvent and dimethylacetamide (mass ratio of 15:85), formulated into a spinning liquid having a solid content of 30% by weight. The viscosity of the spinning liquid was 40 Pa.s, the gel point was -25 ° C, and the gel interval was 8 ° C. A stainless steel metal fiber flask of 10 μm and 0.2 μm was used in times, and the spinning fluid was transferred to the deodorant, and then spun. The spinning liquid is spinning, the spinning liquid temperature is 55 ° C, the dry spray section is from -10 ° C, the spray hole is a circular spray hole, the pore diameter is 0.050 m...

Embodiment 2

[0075]Acrylonitrile, acrylic acid (molar ratio of 99.8: 0.02) was added to the n-heptane (the total monomer mass concentration of 6%) according to the ratio, and the molecular weight of 950,000, the molecular weight distribution coefficient was 5.5 by polymerization. The polymer (in which the co-polymer content is 0.02%). The PAN-type polymer obtained by the polymerization was dissolved in dimethyl sulfoxide, formulated into a spinning liquid having a solid content of 5.1% by weight. The viscosity of the spinning liquid was 110Pa.s, the gel point was 14 ° C, and the gel interval was 6 ° C. The non-woven fabric felt fracture of 3 μm and 0.5 μm was used sequentially, and then the spinning liquid was transferred to the deodorant, and then spinned. The spinning liquid is spun, the spinning liquid is 65 ° C, and the dry spray sections are air, the spray hole is a circular spray hole with a pore diameter of 0.065 mm. During the spinning process, two solidified bath grooves are used, and t...

Embodiment 3

[0077]Acrylonitrile, methyl acrylate (molar ratio 94: 6) was sequentially added to the zinc chloride solution (total monomer mass concentration of 25%) in accordance with the ratio, and the molecular weight was 33,000, the molecular weight distribution coefficient was 3.3 by polymerization. The PAN-class polymer (the molar content of the comonomer in it is 6%). The PAN-type polymer obtained by the polymerization was dissolved in dimethylacetamide, formulated into a spinning liquid having a solid content of 10.5 wt%. The viscosity of the spinning liquid was 110Pa.s, the gel point was 9 ° C, and the gel interval was 6 ° C. The stainless steel metal fiber flask of 5 μm and 2 μm was used sequentially, and the spinning fluid was transferred to the deodorant, and then spinned. The spinning fluid is 35 ° C, the spray liquid temperature is from 35 ° C, the dry spray sections are the circular spray hole, the pore diameter of 0.07 mm. During the spinning process, three coagulation baths are u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com