The composite girder having web members with various patterns

A composite beam and steel technology, applied in bridge materials, bridges, bridge construction, etc., can solve the problems of increased shear force, increased bending moment, increased weight, etc., and achieve the effect of improved resistance and reduced node scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, in order to specifically describe the content of the present invention, it will be described in detail with reference to the drawings showing the embodiments.

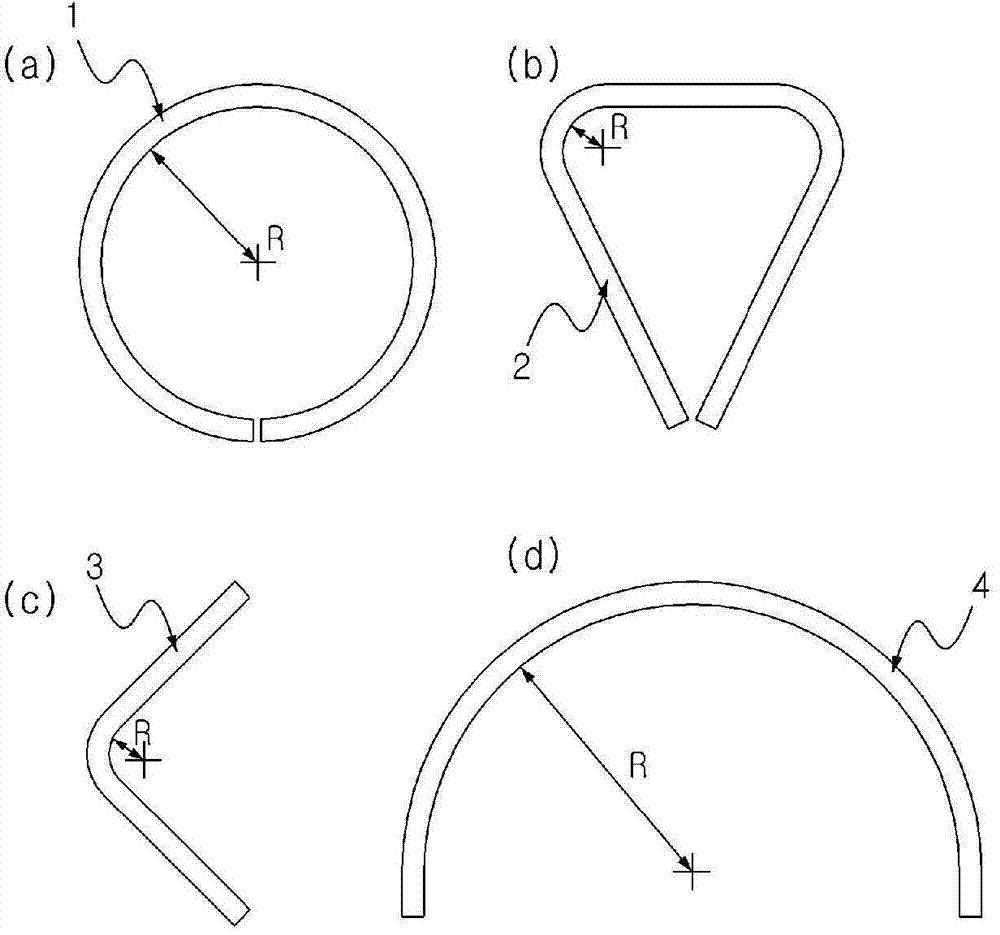

[0057] figure 1 The shape of the unit member used to make the web material of the present invention is shown. Such as figure 1 As shown, the web material of the composite beam of the present invention is made of unit members having a circle 1, a heart 2, an inequality 3, and a semicircle 4, which are bent with a predetermined radius R, so as to be manufactured at certain intervals with multiple Patterned web material.

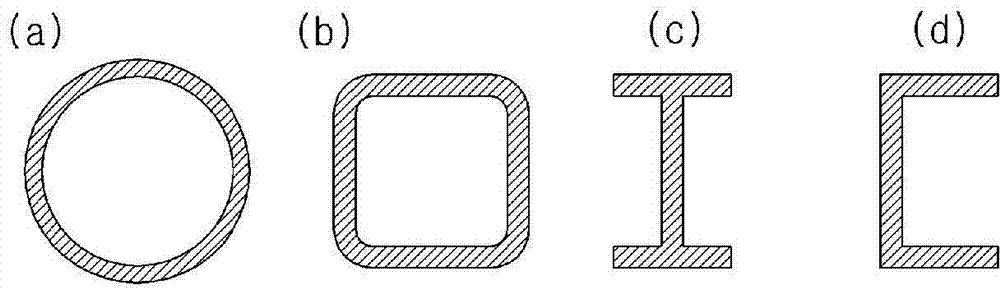

[0058] figure 2 Showing the cross-sectional shape of the unit member of the present invention, it is formed as a cross-section of a circular steel pipe, a square pipe, or a rolled steel (H-shaped steel, C-shaped steel) with minimal change in material properties due to bending.

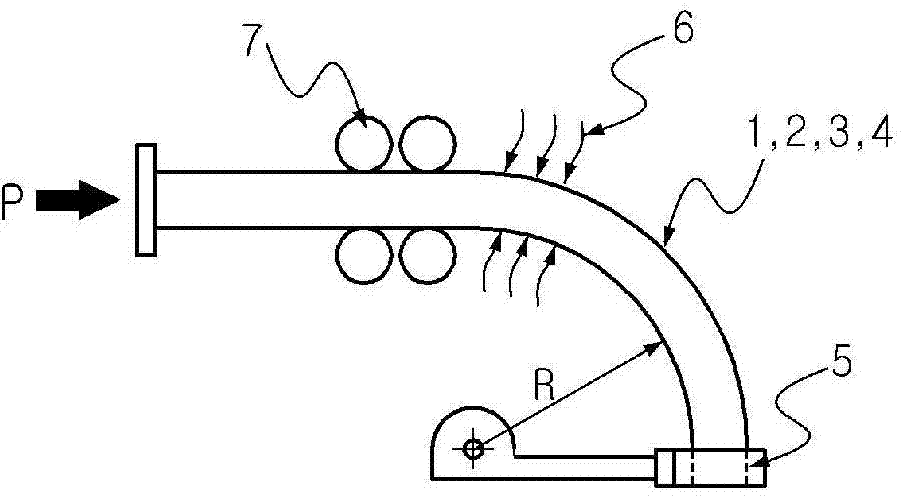

[0059] image 3 is a schematic view showing an apparatus for producing a unit member of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com