Multifunctional processing equipment for substrates

A kind of processing equipment and multi-functional technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of low purification degree, inability to arrange, and inability to arrange hot plates, etc., to avoid temperature fluctuations Uniformity, improvement of product quality, and diversification of processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

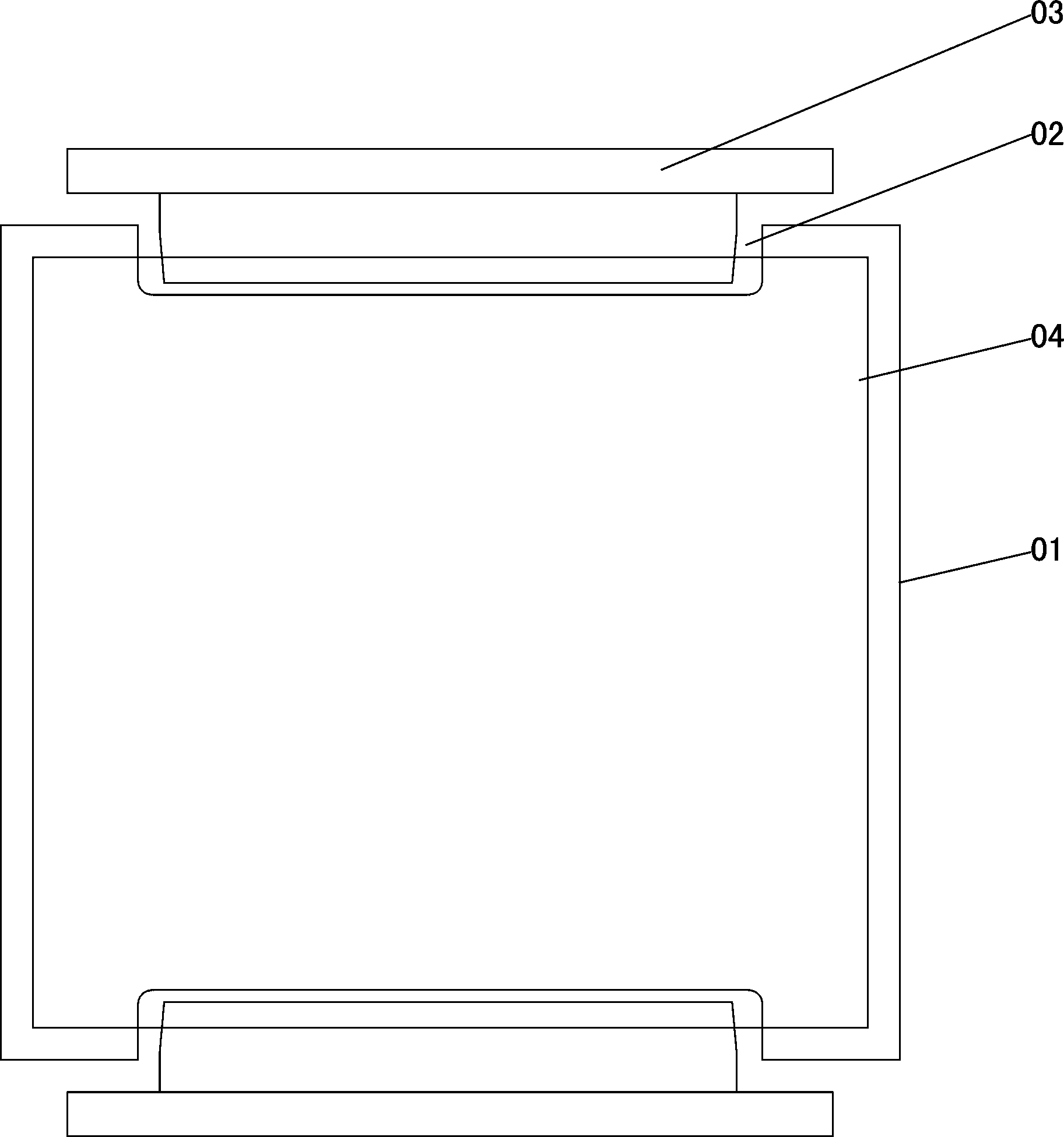

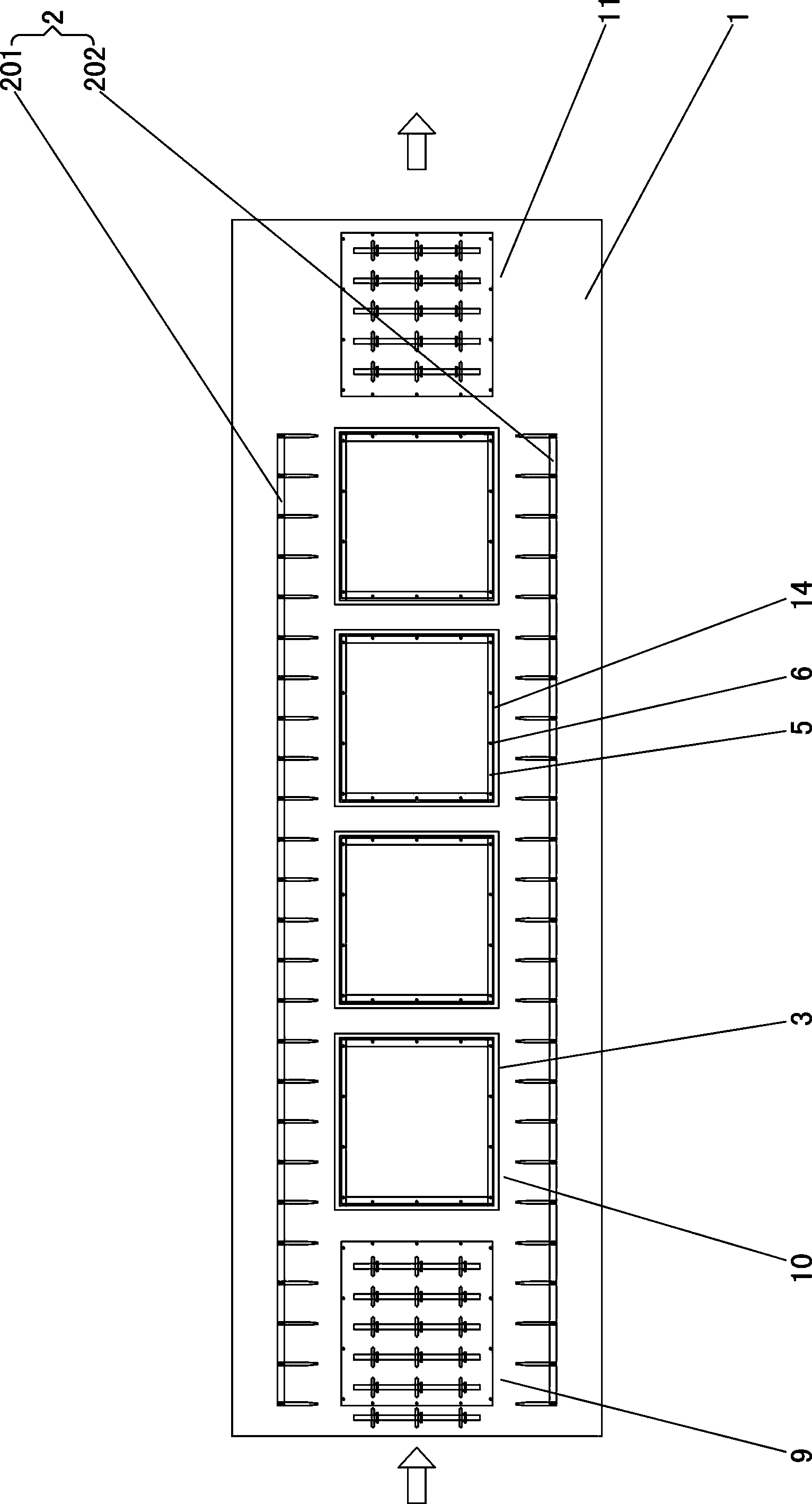

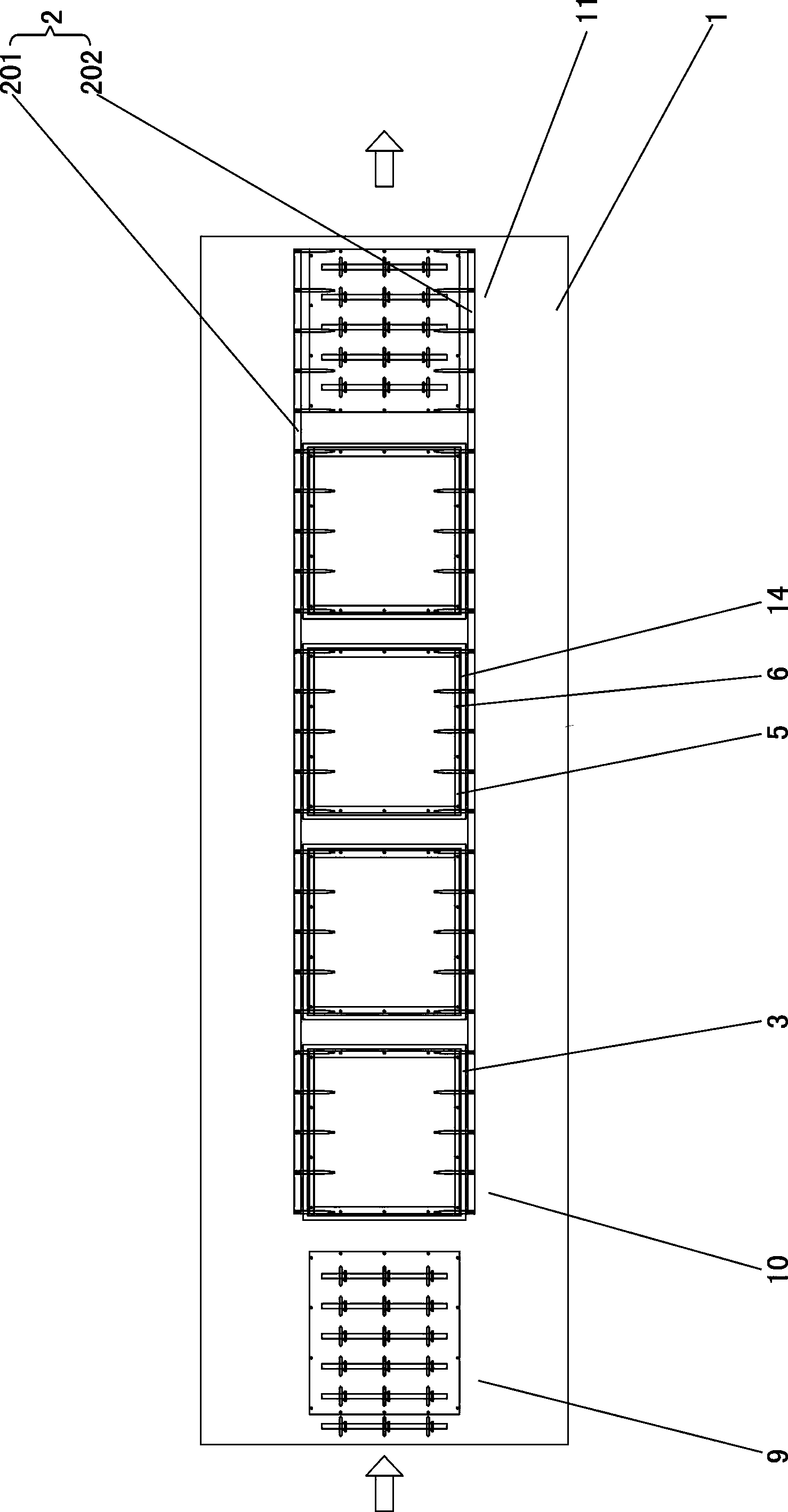

[0033] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, this multifunctional processing equipment for substrates includes a frame 1, a transport mechanism 2, a plurality of processing functional components 3, a frame lifting mechanism 4, a plurality of support frames 5, a plurality of support nails 6 and a plurality of support Rod 7, height adjustment device 8 is also provided on the support rod 7; Feeding station 9, a plurality of processing stations 10 and a discharge station 11 are arranged successively along the conveying direction on the frame 1, and a plurality of processing functional parts 3 Each processing station 10 is arranged in sequence and is on the same level; the edge of each processing function part 3 is provided with a plurality of through holes 12 for the support rod 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com